Exploring the Best Options for Top 3d Printers That Suit Your Business Needs

As the 3D printing industry continues to evolve, businesses are increasingly recognizing the potential of incorporating this technology into their operations. According to a report by Wohlers Associates, the 3D printing market is projected to reach $34.8 billion by 2024, illustrating a compound annual growth rate (CAGR) of 21.0% from 2019 to 2024. This rapid growth underscores the necessity for companies to not only adopt 3D printing but also to select the right equipment. The term "Top 3D Printers" has become synonymous with quality and precision, making it crucial for businesses to explore options that align with their specific needs.

With advancements in materials, software, and printing techniques, the variety of available 3D printers has expanded dramatically. Businesses ranging from automotive to healthcare are leveraging these technologies to streamline production processes, reduce costs, and enhance product customization. According to a survey by Gartner, 69% of manufacturing companies are investing in 3D printing technologies to improve prototypes and reduce time-to-market. This growing trend emphasizes the importance of selecting the right top 3D printers that not only meet technical specifications but also align with business objectives, paving the way for innovation and competitive advantage.

Identifying Key Factors for Choosing the Right 3D Printer for Your Business

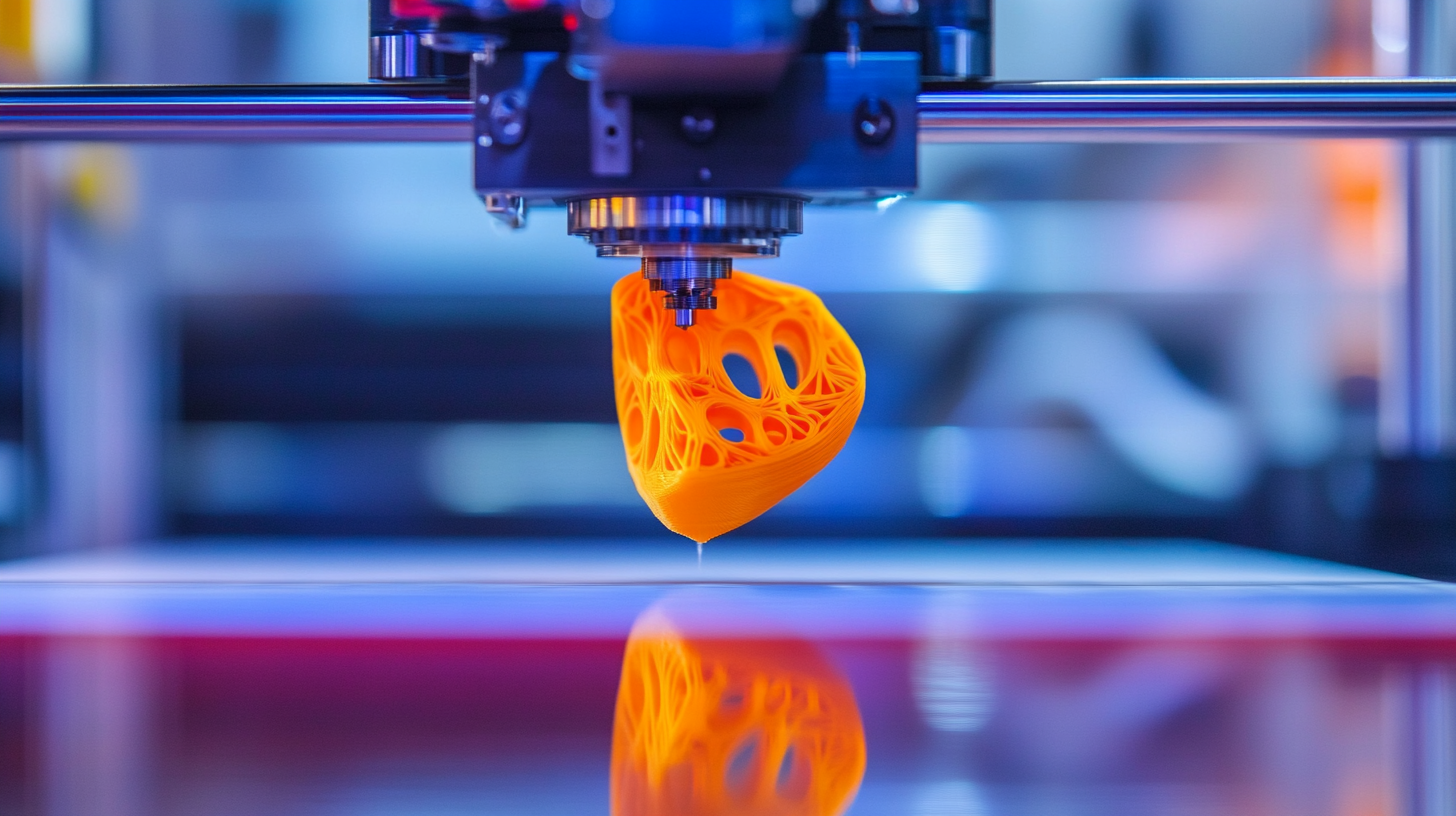

When selecting the ideal 3D printer for your business, it’s vital to consider several key factors that will impact your operations and efficiency. The first consideration is the printer’s technology. There are various printing technologies available, such as Fused Deposition Modeling (FDM), Stereolithography (SLA), and Selective Laser Sintering (SLS). Each technology has its advantages and limitations, thus understanding how each aligns with your business requirements is crucial. Businesses focusing on rapid prototyping may prefer FDM for its speed and cost-effectiveness, while those needing high-resolution prints might lean towards SLA. Next, evaluate the build volume and printer material compatibility. The scale of the projects your business undertakes will dictate the necessary build size of the 3D printer. It's equally important to consider the range of materials that the printer can use, as diverse materials can enhance creativity and product functionality. A printer that supports multiple filaments, including specialty materials, can expand your business capabilities significantly. Finally, don’t overlook the importance of ease of use and maintenance. A user-friendly interface and reliable customer support can save valuable time and resources. Regular maintenance requirements and the availability of replacement parts are also important factors to ensure that your printing operations remain seamless and efficient over time. By thoughtfully considering these key aspects, you can make an informed decision that aligns perfectly with your business objectives.

A Comparative Analysis of Different 3D Printing Technologies

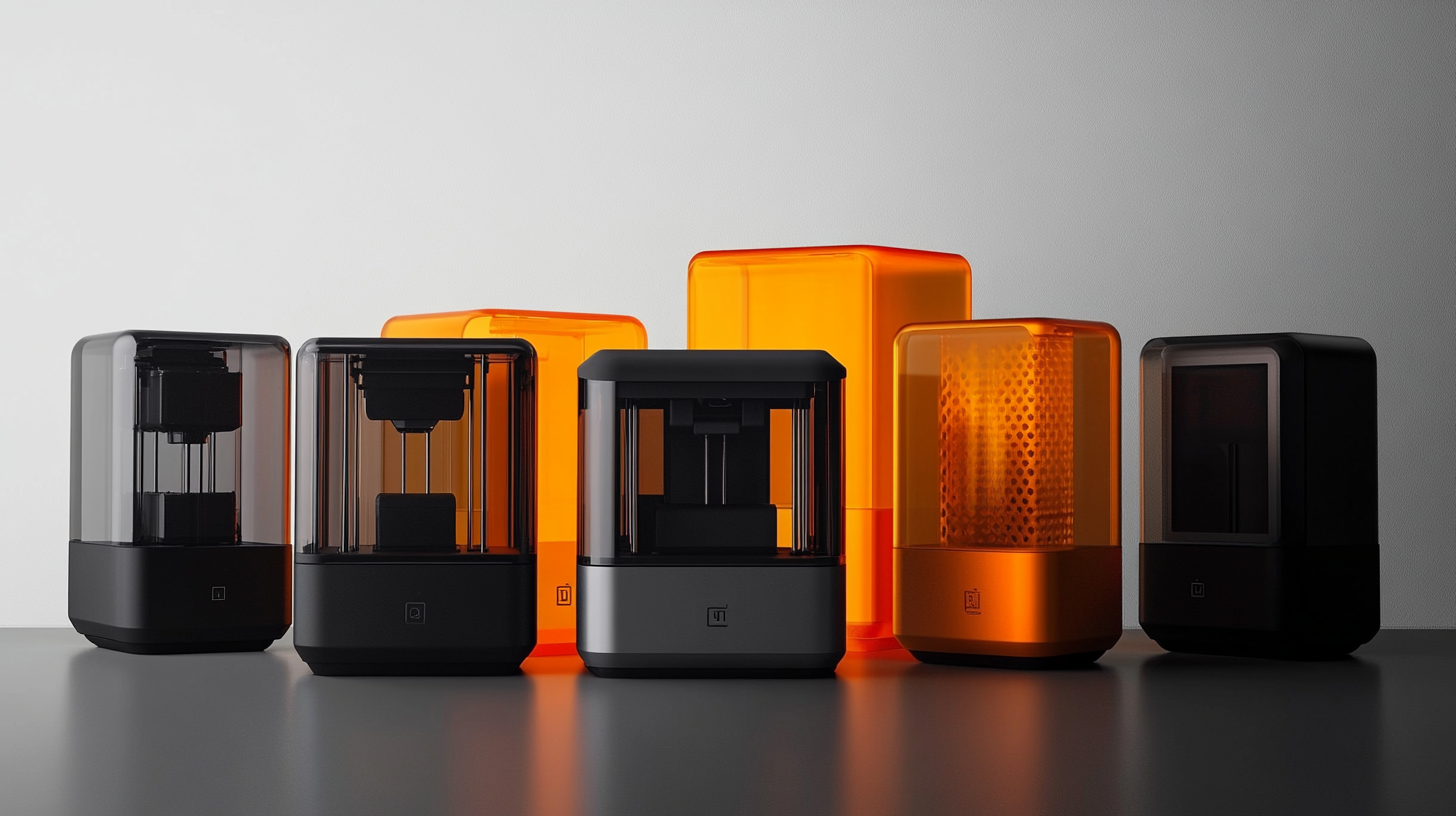

The landscape of 3D printing technology is continuously evolving, offering various solutions tailored to meet diverse business needs. As of 2024, the global 3D printing market has reached an impressive valuation of approximately $19.7 billion. This significant growth underscores the increasing adoption of various 3D printing technologies across multiple industries, including automotive, aerospace, and healthcare.

When comparing different 3D printing technologies, it is essential to recognize the similarities and distinctions among them. Notably, Stereolithography (SLA) and Digital Light Processing (DLP) share a commonality in their operational principles—both utilize liquid photopolymers that solidify under light exposure. This method is highly praised for its precision and the quality of the finished products, making it ideal for industries requiring intricate designs and detailed prototypes.

Moreover, as new players continue to enter the market, advancements in materials and printing speeds are becoming increasingly critical. For instance, the emergence of ceramic 3D printing technologies has initiated a new wave of applications, emphasizing the need for businesses to stay informed about technological advancements. Analysts suggest that companies, much like tech giants such as Apple, may accelerate the technology's evolution, potentially replicating the success seen in CNC machinery. As the industry matures, a comprehensive understanding of these technologies will be vital for businesses looking to leverage 3D printing effectively.

Understanding Material Compatibility for Optimal 3D Printing Results

When selecting a 3D printer for your business, understanding material compatibility is crucial for achieving optimal results. Different 3D printing technologies use various materials, each with its unique properties and applications. For instance, Fused Deposition Modeling (FDM) commonly works with thermoplastics such as ABS and PLA, which are ideal for prototyping and low-volume production. In contrast, Stereolithography (SLA) offers superior surface finish and detail but is typically limited to resin materials, making it more suitable for intricate models or parts requiring high precision.

Another essential aspect to consider is how material compatibility aligns with your specific business needs. If your projects often require durable and functional prototypes, materials like Nylon or PETG might be more appropriate due to their robustness and resistance to impact. Conversely, if your focus is on aesthetic models or complex geometries, specialty resins used in SLA can enhance visual quality and detail, providing an edge in competitive markets. Understanding these material characteristics not only influences the quality of your final products but can also affect production efficiency and cost-effectiveness. This highlights the importance of aligning your choice of 3D printer with the materials that best suit your business objectives.

Evaluating Cost-Effectiveness: Initial Investment vs. Long-Term Benefits

When evaluating the investment in a new 3D printer for your business, a thorough cost-effectiveness analysis becomes essential. The decision to acquire equipment like this often involves a complex balance of initial investment versus long-term benefits. Upfront costs can be substantial, but it’s crucial to consider how this investment will pay off over time through enhanced productivity, quality of output, and the potential for innovation.

In the broader context of sustainable practices, deploying energy-efficient technologies, including advanced 3D printers, aligns with growing trends in corporate responsibility. Just as companies are increasingly evaluating their carbon footprints and exploring renewable energy options, investing in efficient printing solutions can reduce material waste and energy consumption. This not only addresses immediate operational costs but also positions businesses within a market that values sustainability, potentially leading to increased customer loyalty and brand prestige.

Moreover, understanding the ROI of these printing technologies is not just about the financial aspects; it also involves assessing the environmental impacts. Innovations in 3D printing can streamline production processes and minimize excess, thereby contributing to sustainable practices. The cost-benefit analysis should extend beyond financial figures to encompass the societal and ecological ramifications, reassuring stakeholders that the path taken is both economically viable and environmentally responsible.

Exploring Customer Support and Warranty Options for 3D Printers

When considering the acquisition of a 3D printer for your business, customer support and warranty options are crucial factors that should not be overlooked. Reliable customer support can mean the difference between operational downtime and quick solutions to technical issues. As 3D printing technology continues to evolve, manufacturers like Bambu Lab are responding to customer feedback. They've recently promised enhancements such as a ‘Developer Mode’ that allows users greater control over their devices, which can be particularly advantageous for businesses looking to customize their printing processes.

Warranties also play a significant role in the decision-making process. A good warranty can provide peace of mind, ensuring that you're covered in case of mechanical failures or defects. Many printers aimed at small businesses come with comprehensive warranty packages that not only cover repairs but also include technical support. This is essential for minimizing disruption, allowing businesses to maintain productivity without the added stress of unexpected costs.

In conclusion, as you explore the best options for 3D printers, it's clear that robust customer support and generous warranty programs are integral. They not only enhance the user experience but are also pivotal in ensuring that your investment continues to serve your business needs effectively over time.