How to Choose the Right Industrial 3D Printer for Your Business Needs

As the demand for customized manufacturing solutions continues to rise, choosing the right industrial 3D printer has become a critical decision for businesses aiming to enhance their production capabilities. According to a recent report by Wohlers Associates, the global 3D printing industry is projected to reach $44.5 billion by 2026, a testament to the growing significance of this technology in various sectors. Industrial 3D printers offer unmatched precision, flexibility, and speed in producing complex geometries and prototypes, which traditional manufacturing methods often struggle to achieve. With an array of models and technologies available, from FDM to SLA and SLS, businesses must carefully evaluate their specific needs, production volume, and material requirements to ensure that their chosen solution aligns with their operational goals. This tutorial aims to guide you through the essential considerations for selecting the most suitable industrial 3D printer tailored to your business needs.

Understanding Your Business Requirements for 3D Printing Solutions

Choosing the right industrial 3D printer for your business requires a clear understanding of your specific requirements. With the rapid advancement of 3D printing technology, businesses must assess their needs in terms of material capabilities, production volume, and intended applications. For instance, companies in the dental industry are witnessing significant growth, with the market projected to increase substantially over the next decade. This emphasizes the importance of selecting a printer that can deliver precision and quality specific to dental applications.

Additionally, exploring non-metal and non-polymer 3D printing solutions can expand your business's potential. Innovative startups are emerging with unique approaches that leverage alternative materials for diverse applications, potentially transforming how products are developed. By analyzing your business needs and keeping an eye on industry trends, you can identify the technologies and solutions that will best support your objectives and enhance your competitive edge in the market.

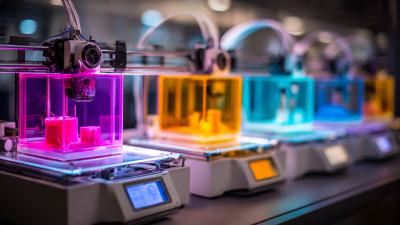

Exploring Different Types of Industrial 3D Printers Available

When exploring the different types of industrial 3D printers available, businesses must first understand their specific needs and the capabilities of each technology. Fused Deposition Modeling (FDM) is one of the most common methods, ideal for prototyping and small production runs. According to a report by Markets and Markets, the FDM segment holds a significant market share, projected to grow from 2.5 billion USD in 2021 to 5.2 billion USD by 2026. This growth highlights its reliability and efficiency for businesses looking to produce functional parts quickly.

Another viable option is Selective Laser Sintering (SLS), which excels in producing complex geometries and customized products. SLS printers utilize powdered materials and a focused laser to create solid structures, enabling greater design freedom. A study by SmarTech Analysis indicates that the SLS market is expected to see a compound annual growth rate (CAGR) of 20% through 2025, making it a crucial technology for businesses looking to innovate.

**Tip:** When selecting a printer, consider the materials you'll need. Different printers are compatible with various filaments and powders, impacting your production capabilities.

**Tip:** Evaluate your volume requirements. If your business anticipates high production needs, invest in an industrial printer that offers scalability. More advanced models can provide faster build times and larger build volumes, ultimately enhancing your operational efficiency.

Key Features to Consider When Selecting a 3D Printer

When selecting an industrial 3D printer for your business, focusing on key features is essential to ensure it meets your operational needs. According to a report by Wohlers Associates, the global 3D printing industry is projected to grow from $12.6 billion in 2020 to over $35 billion by 2024. This growth is driven by advancements in technology, which have made printers more accessible and versatile. Businesses should consider factors such as printing technology, material compatibility, build volume, and speed. For instance, Fused Deposition Modeling (FDM) printers might be suitable for functional prototypes, while Stereolithography (SLA) or Selective Laser Sintering (SLS) technologies are better for producing high-resolution and complex geometries.

Another vital aspect to consider is the printer's software capabilities. A good 3D printer should integrate seamless design-to-print workflows. Based on a survey conducted by 3D Hubs in 2022, 64% of professionals reported that software compatibility was a crucial deciding factor in their printer selection. Furthermore, the ease of use and technical support provided by the manufacturer play critical roles, especially for businesses lacking in-house expertise. Investing in a printer that offers robust customer service can significantly reduce downtime and facilitate smoother operations, contributing to overall productivity gains in your manufacturing processes.

How to Choose the Right Industrial 3D Printer for Your Business Needs - Key Features to Consider When Selecting a 3D Printer

| Feature | Description | Importance | Example Use Cases |

|---|---|---|---|

| Build Volume | The maximum size of the object that can be printed. | Critical for large parts or multiple part production. | Prototyping large components, tooling. |

| Material Compatibility | Types of materials that can be used (plastics, metals, ceramics). | Essential for functional parts and specific applications. | Automotive parts, aerospace components. |

| Print Speed | Rate at which the printer can produce objects. | Affects turnaround time, especially for production runs. | Mass production of small parts. |

| Resolution | Level of detail the printer can achieve. | Important for aesthetic and functional parts. | Medical implants, intricate models. |

| User Interface | Ease of use in operation and setup. | Can affect training time and operational efficiency. | User-friendly for quick prototyping. |

| Post-Processing Requirements | Need for additional finishing steps after printing. | Impacts overall production workflow. | Parts requiring sanding or painting. |

Evaluating Cost-Effectiveness and Return on Investment

When selecting an industrial 3D printer, evaluating cost-effectiveness and return on investment (ROI) is crucial for making a well-informed decision. First, consider the initial capital cost of the printer, which includes purchasing price, installation, and training expenses. However, this first figure is only part of the equation; it's essential to look beyond up-front costs and analyze long-term financial implications. With the right model, savings can accrue through reduced material waste and increased production speed.

Tip 1: Conduct a detailed cost analysis that includes ongoing operating expenses, such as materials, maintenance, and labor. Compare these figures against projected output and sales to forecast potential ROI over time.

Another important aspect is to assess the printer's versatility and scalability. A printer that can handle multiple materials or product lines may offer better cost efficiency in the long run. This flexibility allows businesses to adapt to changing market demands without incurring significant additional costs.

Tip 2: Research case studies from businesses of similar sizes and sectors that have integrated 3D printing technologies. Understanding their ROI can provide invaluable insight into what you can realistically expect from your investment.

Future Trends in Industrial 3D Printing Technology to Watch

The landscape of industrial 3D printing is rapidly evolving, shaped by emerging technologies that promise to redefine manufacturing processes. One significant trend is the integration of artificial intelligence into 3D printing systems. This development allows for smarter printers that can optimize build processes in real time, reducing waste and improving accuracy. As businesses prioritize efficiency and sustainability, AI-enhanced printers are expected to gain popularity, making them a vital consideration for companies looking to invest in 3D printing technologies.

Another trend to watch is the rise of advanced materials. The expansion of material options is crucial for industries that require specific mechanical properties, from aerospace to healthcare. Innovative materials such as bio-based plastics and high-performance composites are steadily becoming more accessible, enabling businesses to create more resilient and functional prototypes and end-products. This shift towards diverse and specialized materials will allow industrial 3D printers to cater to a wider range of applications, enhancing their versatility and appeal in various sectors.

Trends in Industrial 3D Printing Technology

Related Posts

-

Understanding Industry Standards for Choosing the Best Fast 3D Printer for Your Business Needs

-

Innovative Solutions Beyond Top 3D Printers for Your Manufacturing Needs

-

Top Choices for Best 3 D Printing Solutions Across Global Markets

-

Comprehensive Insights on 3D Printing Materials for Global Buyers

-

Exploring the Unique Features and Uses of the Best Small 3D Printer and How to Choose the Right One

-

Innovative Approaches for Global Buyers of 3D Printing Technology