Understanding Industry Standards for Choosing the Best Fast 3D Printer for Your Business Needs

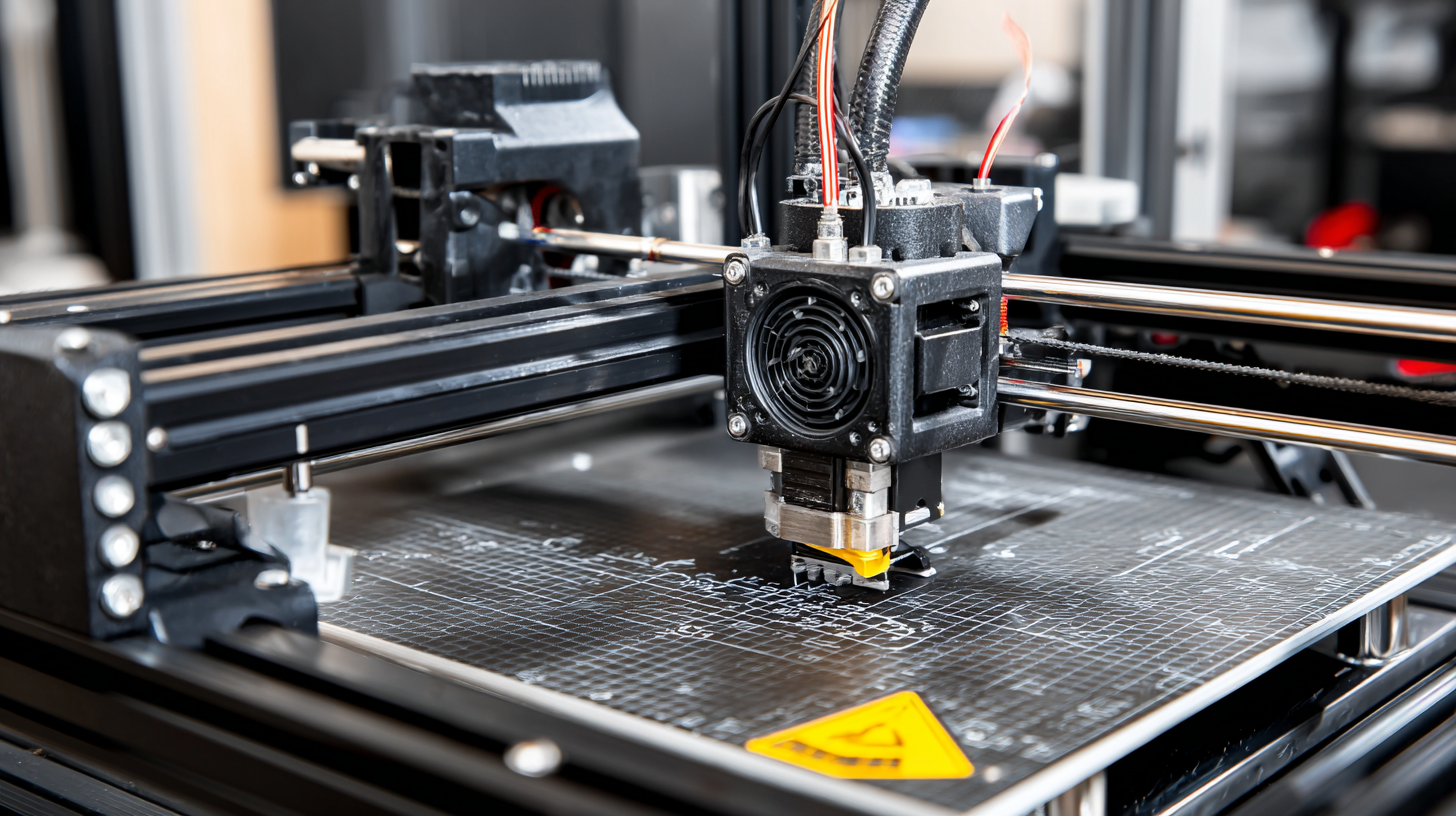

In today's rapidly evolving manufacturing landscape, the demand for speed and precision is more critical than ever, particularly as businesses strive to remain competitive. Fast 3D printers have emerged as a vital tool in this quest, revolutionizing production processes across various industries.

According to a report by SmarTech Analysis, the global market for 3D printing is expected to surpass $32 billion by 2026, with fast 3D printing solutions leading the charge due to their ability to significantly reduce production times and costs.

As companies seek to optimize their operations, understanding the key industry standards and technology advancements related to fast 3D printers becomes essential for making informed decisions.

This blog will delve into the critical factors to consider when selecting the best fast 3D printer tailored to your business needs, ensuring you stay ahead in a competitive market.

The Importance of Understanding Industry Standards in 3D Printing

In the rapidly evolving world of 3D printing, understanding industry standards is crucial for businesses seeking to adopt this technology effectively. These standards define the quality, safety, and interoperability of 3D printers, ensuring that products meet specific requirements and can be seamlessly integrated into existing workflows. By familiarizing themselves with industry benchmarks such as ISO norms and ASTM standards, businesses can make informed decisions when selecting a fast 3D printer that fits their unique operational needs.

Adhering to industry standards not only enhances the reliability of 3D printing processes but also fosters trust among clients and stakeholders. When a company utilizes printers that comply with recognized regulations, it signals a commitment to quality and accountability, which can be a significant competitive advantage. Moreover, understanding these standards can help businesses identify the right materials and technologies that are compatible with their selected printers, ultimately leading to improved efficiency, lower production costs, and better end products.

Key Market Trends Shaping the Fast 3D Printer Industry by 2025

The fast 3D printer industry is poised for significant growth, driven by several key market trends projected to shape the landscape by 2025. According to a report by Smithers Pira, the global 3D printing market is expected to reach $34.8 billion by 2025, demonstrating a compound annual growth rate (CAGR) of 23%. This surge is largely attributed to advancements in material science and an increasing demand for rapid prototyping across various sectors, including automotive and healthcare.

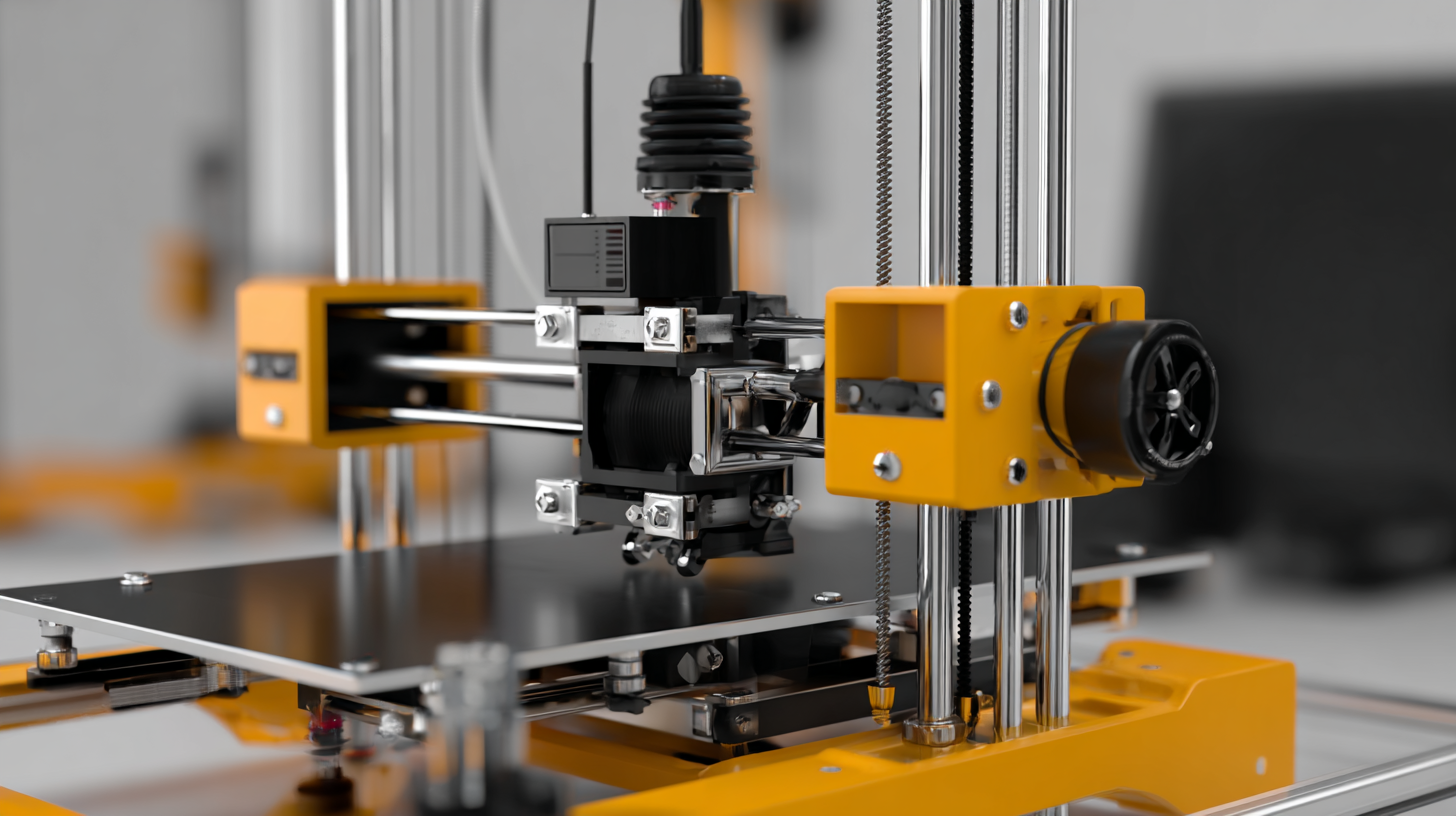

Another pivotal trend is the rise of additive manufacturing technologies that enhance speed and efficiency. A recent analysis by Wohlers Associates states that innovations like Continuous Liquid Interface Production (CLIP) and Multi Jet Fusion (MJF) are revolutionizing production, significantly reducing print times while maintaining high-quality outputs. Businesses that prioritize these cutting-edge technologies will likely gain a competitive edge, as consumer expectations for faster turnaround times and personalized products continue to rise.

Moreover, with sustainability becoming a central focus, manufacturers are exploring eco-friendly materials and processes. The adoption of biodegradable filaments and energy-efficient printers is expected to not only meet regulatory demands but also appeal to environmentally-conscious consumers. As these trends evolve, companies must stay informed and adaptable to leverage the opportunities within this dynamic industry.

Comparative Analysis of Fast 3D Printer Technologies and Their Applications

In the rapidly evolving 3D printing landscape, selecting the right technology for your business hinges on understanding the diverse applications and capabilities of various systems. Notably, the dental industry has embraced 3D printing, utilizing technologies like Stereolithography (SLA) and Fused Deposition Modeling (FDM) to create accurate dental models and custom prosthetics. In-office and in-lab printers serve distinct needs, with in-office systems facilitating immediate patient care and in-lab printers providing high-volume production capabilities.

Beyond dentistry, industries such as aerospace and automotive are leveraging advanced 3D printing techniques like Selective Laser Sintering (SLS) and Direct Metal Laser Sintering (DMLS) for prototyping and manufacturing complex components. These technologies not only allow for lightweight structures but also enhance performance with innovative materials. As organizations explore these dynamic applications, understanding the strengths of each 3D printing technology becomes crucial in meeting specific business requirements and staying competitive in the market.

Understanding Industry Standards for Choosing the Best Fast 3D Printer for Your Business Needs

| Technology | Printing Speed (mm/s) | Layer Height (mm) | Build Volume (mm) | Materials Supported | Typical Applications |

|---|---|---|---|---|---|

| Fused Deposition Modeling (FDM) | 50 - 300 | 0.1 - 0.5 | 300 x 300 x 400 | PLA, ABS, PETG, TPU | Prototyping, Functional Parts |

| Stereolithography (SLA) | 20 - 150 | 0.025 - 0.1 | 200 x 200 x 300 | Resin | Dental, Jewelry, Miniatures |

| Selective Laser Sintering (SLS) | 10 - 50 | 0.1 - 0.15 | 400 x 400 x 450 | Nylon, Polyamide | Complex Geometries, Functional Testing |

| Digital Light Processing (DLP) | 20 - 200 | 0.05 - 0.2 | 120 x 68 x 160 | Resin | Rapid Prototyping, Medical Models |

| Continuous Liquid Interface Production (CLIP) | 100 - 1000 | 0.025 - 0.1 | 145 x 144 x 175 | Resin | High Detail Items, Functional Parts |

Case Studies: Successful Implementation of Fast 3D Printing in Various Sectors

The utilization of fast 3D printing technology has significantly impacted various sectors, particularly in healthcare and robotics. In the medical field, the ability to produce highly detailed and accurate models is revolutionizing patient treatment plans and surgical procedures. According to a recent industry report, the global 3D printing market in healthcare is projected to reach $6.3 billion by 2025, reflecting a compound annual growth rate (CAGR) of 18.2%. This burgeoning demand is driven by the need for customized medical solutions, including prosthetics and implants, which can be rapidly created through additive manufacturing techniques.

Moreover, in the robotics industry, fast 3D printing is enabling manufacturers to overcome traditional production constraints. The technology facilitates the rapid prototyping of complex designs, allowing for iterative testing and improvements in a fraction of the time previously required. Reports indicate that companies adopting 3D printing technologies in their manufacturing processes have seen reductions in material waste by up to 50% and significantly shortened lead times. These advantages not only enhance the innovation cycle but also contribute to cost-efficiency, making fast 3D printing an essential tool in leading-edge industries.

Fast 3D Printing Adoption Across Industries

Evaluating ROI: How Industry Standards Impact Fast 3D Printer Investment Decisions

When considering the investment in a fast 3D printer for your business, evaluating the return on investment (ROI) is crucial. Industry standards play a significant role in this assessment, as they provide benchmarks for performance, reliability, and cost-effectiveness. By understanding these standards, businesses can make informed decisions that align with their specific needs and operational goals. For instance, printers that comply with established industry norms tend to show higher durability and efficiency, directly impacting production costs and time.

Moreover, adhering to industry standards can facilitate scalability and integration into existing workflows. A 3D printer that meets recognized criteria is often easier to integrate with other technologies and processes, ensuring that businesses can expand their capabilities without incurring excessive additional costs. This adaptability not only maximizes the initial investment but also enhances long-term profitability. Ultimately, the right fast 3D printer—supported by thorough knowledge of industry standards—can be a transformative asset, driving innovation and efficiency in any business infrastructure.