The Ultimate Guide to Choosing the Right 3D Printer Filament: Expert Insights and Industry Trends

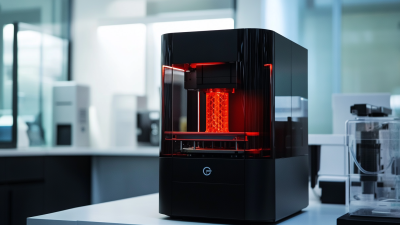

The rapid evolution of 3D printing technology has transformed industries, leading to an unprecedented demand for high-quality 3D printer filament. As reported by Smithers Pira, the global 3D printing materials market is forecasted to reach $12.6 billion by 2028, with filament accounting for a significant portion of this growth. This surge can be attributed to advancements in material science and the increasing adoption of 3D printing across various sectors, including automotive, healthcare, and consumer goods.

Yet, with a myriad of filament options available, selecting the right 3D printer filament can be daunting for both novice and experienced users. This guide will delve into expert insights and the latest industry trends to help you navigate this complex landscape, ensuring that your 3D printing projects are not only successful but also aligned with the best practices in the industry.

Understanding Different Types of 3D Printer Filaments: A Comprehensive Overview

When venturing into the world of 3D printing, understanding the diverse range of filaments available is crucial for achieving optimal results. The most common types include PLA, ABS, PETG, and TPU, each offering unique properties that cater to different applications. According to a recent market report from MarketsandMarkets, the 3D printing filament market is anticipated to grow from $1.2 billion in 2023 to $2.3 billion by 2028, highlighting the increasing demand for specialized materials in various industries.

PLA, known for its ease of use and biodegradability, is favored by beginners and educators for printing prototypes and educational models. ABS, offering greater strength and thermal resistance, is popular among professionals for creating durable parts. In contrast, PETG sits between PLA and ABS in terms of flexibility and strength, making it suitable for products that require a balance of durability and ease of printing. As reported by Smartech Analysis, the largest share of the filament market is dominated by PLA, which is projected to account for over 50% of the overall market due to its accessibility and user-friendly characteristics. Understanding these distinctions will aid in making informed decisions when selecting the perfect filament for your 3D printing needs.

Key Factors to Consider When Choosing the Right 3D Printer Filament

When selecting the right 3D printer filament, several key factors come into play that can significantly affect the outcome of your projects. First, material compatibility is crucial; not all filaments are suitable for every printer. According to a recent industry report by 3D Printing Industry, PLA (Polylactic Acid) and ABS (Acrylonitrile Butadiene Styrene) are among the most widely used materials due to their ease of use and availability.

PLA offers a lower printing temperature and is biodegradable, making it an excellent choice for beginners, while ABS is favored for its durability and heat resistance, suited for functional parts.

Another critical aspect to consider is the filament diameter and consistency. The American Society for Testing and Materials (ASTM) suggests maintaining a tolerance of ±0.02mm on filament diameter to ensure reliable printing. Inconsistent filament can lead to clogging and poor print quality. Furthermore, color and finish options are increasingly important in the industry; as reported by SmarTech Analysis, the demand for specialty filaments, including those with metallic or flexible qualities, has grown considerably, constituting over 25% of the market share in recent years. Understanding these factors will guide you in making informed choices that align with your specific 3D printing needs.

Exploring Popular Filament Materials: PLA, ABS, PETG, and More

When selecting the right 3D printer filament, understanding the characteristics of popular materials such as PLA, ABS, and PETG is crucial for achieving optimal results. PLA is widely appreciated for its affordability and ease of use, making it a favorite among hobbyists. Recent studies highlight the mechanical properties of PLA under various printing parameters, showcasing its suitability for a range of applications in the FDM process. Interestingly, innovations in PLA processing techniques over the last three years have further enhanced its performance, promoting its use in more complex designs.

ABS, on the other hand, is known for its durability and impact resistance, often chosen for projects requiring tougher materials. However, newer alternatives like PETG are gaining traction due to their excellent layer adhesion and chemical resistance while being easier to print compared to ABS. As the 3D printing market evolves, the filament recycler market is also on the rise, projected to reach USD 2.85 billion by 2034, with a CAGR of 23.16% from 2025-2034, highlighting the increasing focus on sustainability in filament choices. This shift toward environmentally friendly materials offers exciting opportunities for hobbyists and professionals alike in maximizing their 3D printing ventures.

Industry Trends: Innovations in 3D Printing Filament Technology

The world of 3D printing filament technology is constantly evolving, with innovations setting new standards for quality and performance. One of the most notable trends is the development of eco-friendly filament options. Brands are now offering biodegradable materials such as PLA derived from renewable resources, which not only meets the needs of environmentally conscious consumers but also enhances the sustainability of 3D printing practices.

When selecting the right filament, it's crucial to consider the material properties that align with your project requirements. For example, if you're printing functional prototypes, consider using Nylon or PETG for their superior strength and flexibility. Additionally, explore the emerging flexible filaments that provide versatility for various applications.

Tips: Always check compatibility with your printer’s hotend and settings for optimal results. Experimenting with different filaments can help discover unique finishes and effects, such as wood-infused or metal-infused filaments, which can add a creative touch to your projects. Keep an eye on industry trends, as staying informed can empower you to make strategic choices and enhance your 3D printing experience.

Expert Tips for Maintaining and Storing Your 3D Printer Filament

When it comes to 3D printing, the quality of your filament can significantly affect the outcome of your projects. Therefore, maintaining and storing your 3D printer filament properly is essential for achieving optimal results. One of the key tips is to keep your filament in a cool, dry environment. Filaments, especially those made from hygroscopic materials like PLA and Nylon, can absorb moisture from the air, leading to prints that are brittle or have surface defects. To combat this, consider using airtight containers with desiccants to draw out any moisture, ensuring that your filament remains in peak condition.

When it comes to 3D printing, the quality of your filament can significantly affect the outcome of your projects. Therefore, maintaining and storing your 3D printer filament properly is essential for achieving optimal results. One of the key tips is to keep your filament in a cool, dry environment. Filaments, especially those made from hygroscopic materials like PLA and Nylon, can absorb moisture from the air, leading to prints that are brittle or have surface defects. To combat this, consider using airtight containers with desiccants to draw out any moisture, ensuring that your filament remains in peak condition.

Another important aspect of filament maintenance is protecting it from UV light and extreme temperatures. Extended exposure to sunlight can degrade the filament, impacting its mechanical properties and color fidelity. It’s advisable to store the filaments in opaque containers or bags that block UV rays. Additionally, be mindful of temperature fluctuations; storing your filament in a climate-controlled area will help prevent warping and other issues that can affect print quality. By following these expert tips for maintaining and storing your 3D printer filament, you'll not only extend its lifespan but also enhance the overall quality of your 3D prints.

Related Posts

-

Maximizing Efficiency in 3D Printing with Advanced Material Selection Techniques

-

5 Digital Tips for Maximizing Efficiency with Your Carbon 3D Printer

-

Unlocking the Secrets to Sourcing High-Quality 3D Printer Filament for Your Business

-

Leading the Charge: Explore the Superiority of China's Best Carbon 3D Printers for Global Buyers

-

Explore the Rise of Beginner 3D Printers at the 137th Canton Fair in Guangzhou

-

Innovative Approaches for Global Buyers of 3D Printing Technology