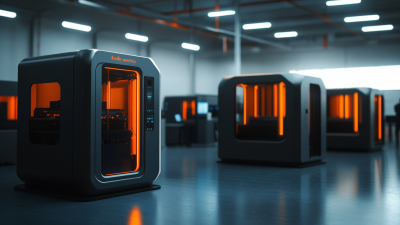

How to Choose the Right Carbon 3D Printer for Your Business Needs

When it comes to revolutionizing your business's manufacturing capabilities, selecting the right Carbon 3D printer is a critical step that can greatly influence your production efficiency and product quality. With a plethora of options available in the market today, understanding the specific needs of your business becomes paramount. This guide aims to help you navigate the intricate landscape of Carbon 3D printing technology, highlighting essential factors such as printing speed, material compatibility, and post-processing requirements. By carefully assessing these elements, you can make an informed decision that aligns perfectly with your business objectives, ensuring that your investment in a Carbon 3D printer yields maximum returns and facilitates innovation in your production processes. Whether you are a small startup or an established enterprise, the right Carbon 3D printer can transform your approach to design and manufacturing, opening new avenues for growth and creativity.

Understanding Your Business Requirements for 3D Printing

Choosing the right carbon 3D printer for your business begins with a clear understanding of your specific printing needs. According to a report by Wohlers Associates, the global 3D printing industry is expected to grow from $12.6 billion in 2020 to over $35.6 billion by 2024. This rapid growth highlights the increasing reliance on 3D printing technologies across various sectors, making it essential for businesses to align their operations with these advancements.

To begin with, you must evaluate the types of materials you will be using. Carbon’s technology is particularly notable for its ability to print with a range of advanced composite materials, which can be a game-changer in industries like aerospace and automotive, where precision and strength are paramount. Additionally, understanding print volume and speed is crucial; for example, the average production time for a carbon 3D printed part can be significantly lower than traditional methods, which can increase productivity and reduce lead times. According to a study by SmarTech Analysis, 80% of manufacturers report that the ability to rapidly prototype and produce end-use parts is a decisive factor in their adoption of 3D printing technology. These insights put the focus firmly on evaluating how a printer’s capabilities align not just with current projects, but also with long-term business strategy.

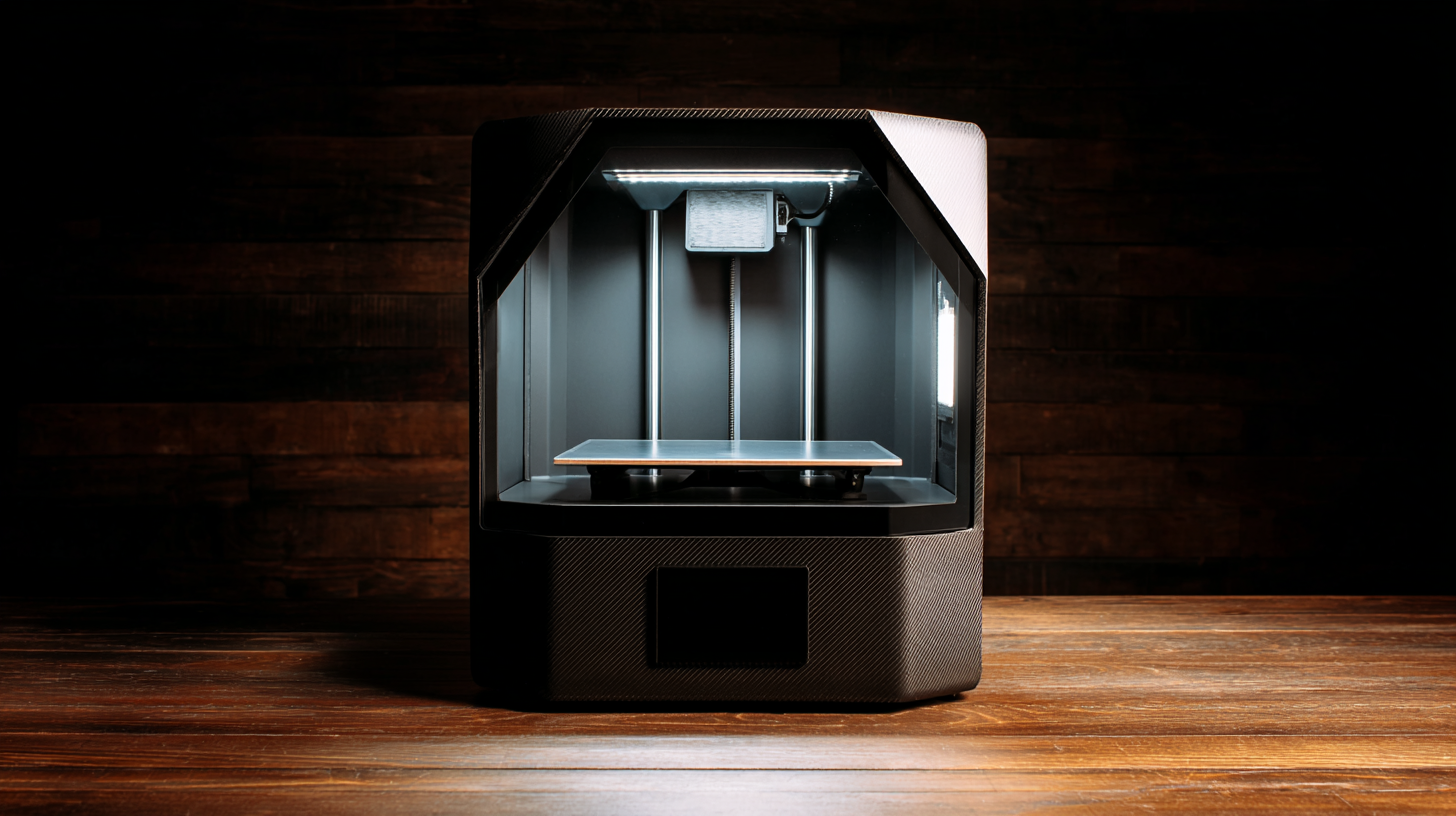

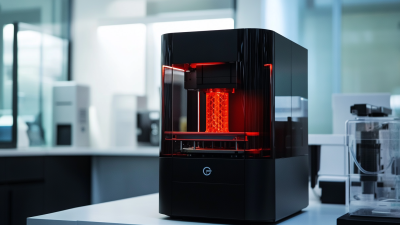

Key Features to Look for in Carbon 3D Printers

When selecting a Carbon 3D printer for your business, it's essential to focus on key features that align with your production needs. One of the most critical aspects is the print volume. Depending on the size of the objects you intend to create, larger build volumes can significantly enhance your workflow and efficiency.

Another feature to consider is the resolution and layer thickness capabilities. Higher resolutions allow for more detailed prints, which can be crucial for industries that require precision, such as medical or aerospace applications. Additionally, look for models that offer a range of layer thickness settings, enabling versatility in production speed and detail.

**Tips:** Prioritize printers that offer user-friendly software and a strong support network. This will streamline the integration process into your business and ensure that you have assistance when troubleshooting issues. Always evaluate the material compatibility of the printer to ensure it can work with the specific resins or materials your projects require.

Comparison of Key Features in Carbon 3D Printers

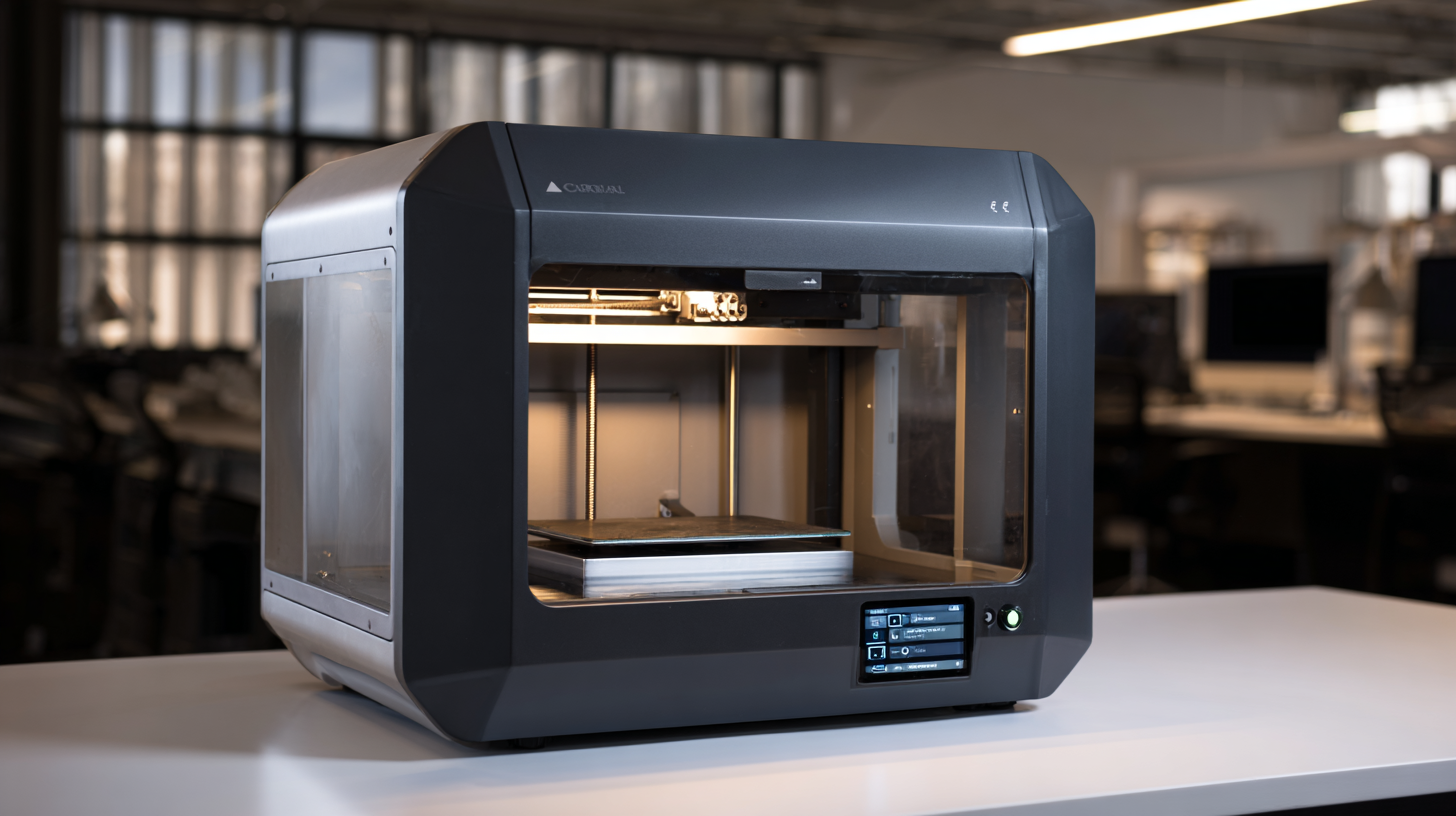

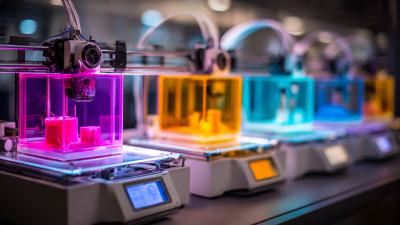

Comparing Different Models Based on Performance and Cost

When selecting a carbon 3D printer for your business needs, it's crucial to compare different models based on both performance and cost. According to a recent industry report by Wohlers Associates, the average cost of professional-grade 3D printers ranges from $5,000 to over $100,000, depending on technical capabilities and applications. This wide price spectrum highlights the importance of aligning your budget with the printer's intended performance outcomes.

**Tip:** Always consider the total cost of ownership, including maintenance and material expenses, not just the upfront price. Certain models may have lower initial costs but could end up being more expensive in the long run due to higher consumable prices or operational inefficiencies.

Performance metrics such as print speed, layer resolution, and build volume are essential to evaluate when selecting a model. A study from the 3D Printing Industry states that carbon printers can achieve layer resolution as fine as 25 microns, resulting in smoother finishes and more intricate designs. Investing in a high-performance printer that meets your specific business needs can significantly enhance production capabilities and product quality.

**Tip:** Before making a purchase, request demo prints or trial periods from suppliers to better understand the performance metrics in real-world scenarios. This hands-on experience can provide invaluable insights and help inform your decision.

How to Choose the Right Carbon 3D Printer for Your Business Needs - Comparing Different Models Based on Performance and Cost

| Model | Print Speed (mm/h) | Build Volume (mm) | Layer Height (microns) | Material Compatibility | Cost (USD) |

|---|---|---|---|---|---|

| Model A | 150 | 300 x 300 x 300 | 50 | PLA, ABS, Nylon | 2,500 |

| Model B | 120 | 400 x 400 x 400 | 75 | PLA, TPU | 3,200 |

| Model C | 200 | 250 x 250 x 250 | 100 | PETG, HIPS | 2,000 |

| Model D | 180 | 350 x 350 x 300 | 50 | ASA, Wood Filament | 3,000 |

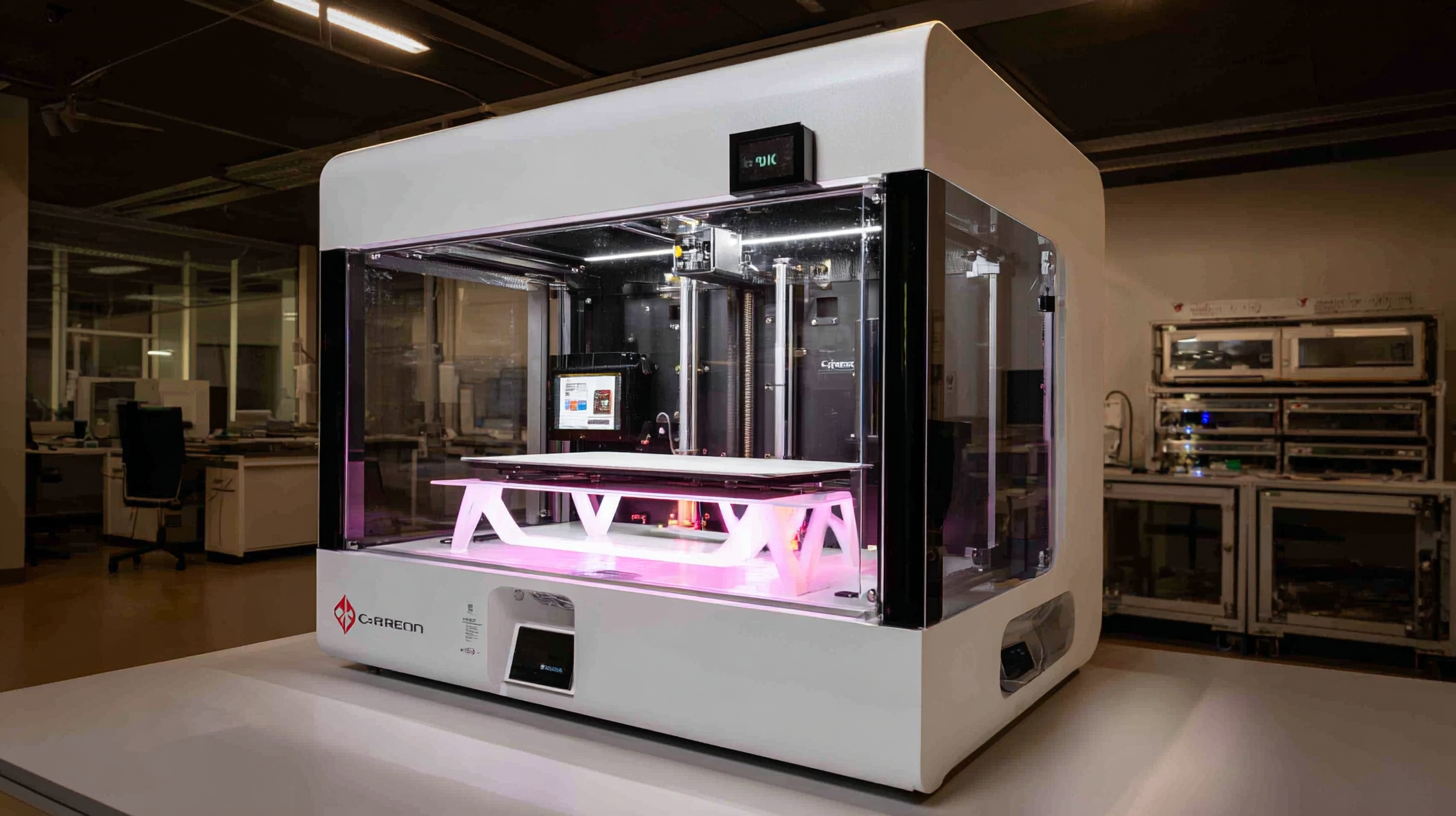

Evaluating Material Compatibility for Your Projects

When selecting a carbon 3D printer tailored to your business needs, evaluating material compatibility is paramount. Different printers boast varying capacities for handling a wide array of materials, such as resin, thermoplastics, and composites. Understanding the specific requirements of your projects, including strength, flexibility, and finish, can help narrow down your choices. For example, if your business focuses on prototyping functional parts, consider a printer that supports engineering-grade materials which offer superior mechanical properties.

Moreover, specific industries may have unique demands for material compatibility. For instance, the aerospace sector often requires materials that meet stringent certification standards, while the medical field might prioritize biocompatibility. It is essential to ensure that the 3D printer you choose can accommodate the necessary material types and specifications. Engaging in thorough research and consulting user reviews can provide deeper insights into how well a printer performs with your selected materials, ultimately leading to better decision-making that aligns with your business objectives.

Assessing Support and Maintenance Services for Long-term Use

When selecting a carbon 3D printer for your business, it’s crucial to assess the support and maintenance services provided by the manufacturer. A reliable support system can significantly impact the longevity and efficiency of your printing operations. Look for companies that offer comprehensive technical support, including troubleshooting and quick response times in case of issues. An established service network ensures that you have access to qualified technicians who understand your specific equipment, minimizing downtime and keeping your production on track.

**Tips:**

1. Inquire about the availability of on-site support versus remote assistance. On-site visits can be critical for complex issues that require hands-on intervention.

2. Consider the availability of replacement parts and the manufacturer’s policies on warranty and service agreements. Prompt access to parts can reduce the time your printer sits inactive.

Additionally, scrutinizing maintenance services is essential. A well-defined maintenance schedule can help prolong the life of your printer. Opt for manufacturers that provide detailed guidelines for routine maintenance and offer training sessions for your staff. This proactive approach not only ensures optimal performance but can also save costs associated with unexpected repairs.

Related Posts

-

5 Reasons Why You Should Choose the Best Top 3D Printers Today

-

Finding Reliable Vendors for Large 3D Printers to Boost Your Manufacturing Efficiency

-

Exploring Opportunities in Large Format 3D Printing: Highlights from the 137th Canton Fair

-

Leading the Charge: Explore the Superiority of China's Best Carbon 3D Printers for Global Buyers

-

Future of 3D Printing in 2025 Essential Trends and Actionable Checklist for Success

-

Top Choices for Best 3 D Printing Solutions Across Global Markets