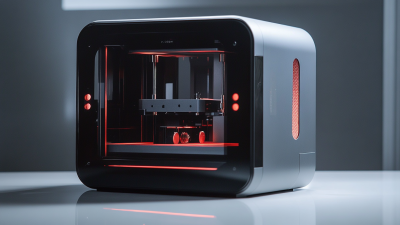

5 Compelling Reasons Commercial 3D Printers Transform Business Efficiency and Innovation

In today's rapidly evolving business landscape, the adoption of Commercial 3D Printers is revolutionizing efficiency and fostering innovation across various industries. According to a report by MarketsandMarkets, the global 3D printing market is expected to reach USD 34.8 billion by 2026, growing at a CAGR of 23% from 2021. This surge highlights the increasing reliance on 3D printing technologies as businesses seek to streamline their operations, reduce costs, and enhance product development processes. Companies are leveraging Commercial 3D Printers not only to produce prototypes but also to manufacture end-use products, enabling them to respond swiftly to market demands. By embracing this transformative technology, organizations can significantly improve their competitive edge while fostering a culture of creativity and innovation, making it an indispensable tool for modern commerce.

Revolutionizing Production Processes with 3D Printing Technology

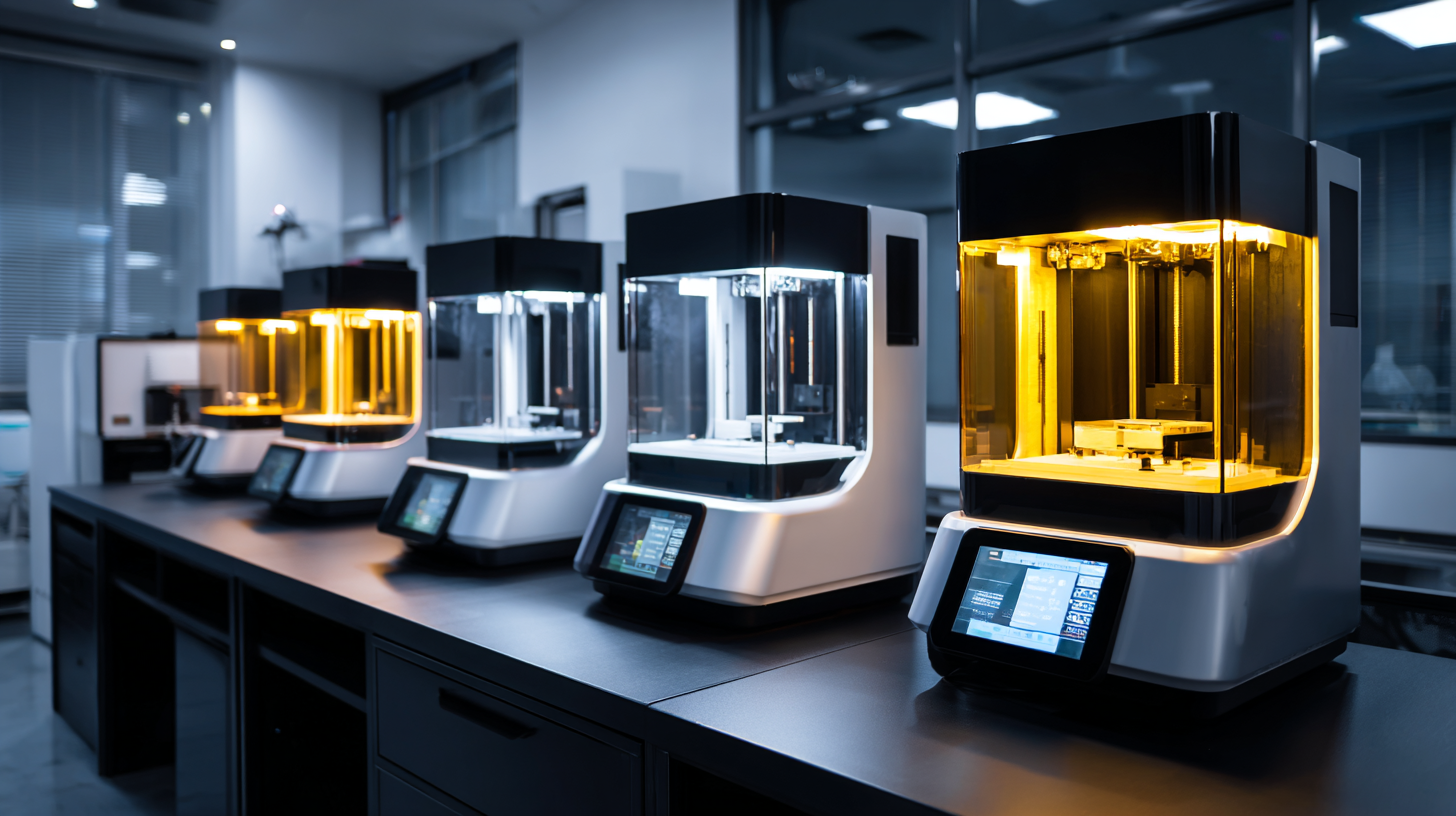

The integration of 3D printing technology into commercial production processes is revolutionizing how businesses develop and manufacture products. According to a report by Wohlers Associates, the global 3D printing market is expected to reach $38.2 billion by 2025, marking a compound annual growth rate (CAGR) of 26.4%. This significant growth highlights the increasing recognition of 3D printing as a vital tool for innovation and efficiency.

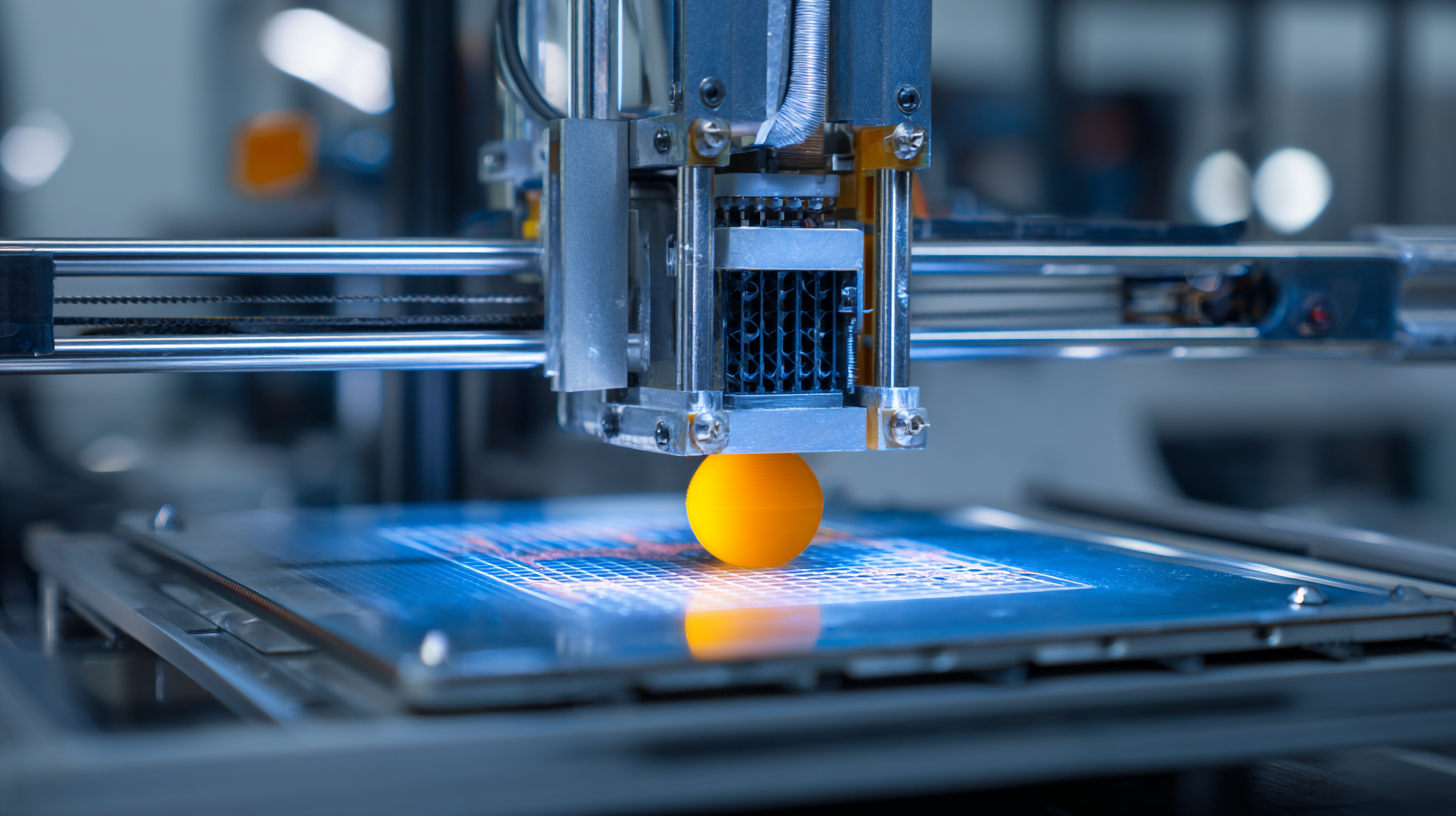

One major way 3D printing enhances production is through rapid prototyping, allowing companies to create and test designs faster than traditional methods. This not only reduces development time but also decreases costs associated with material waste. A survey by Gartner indicates that 75% of organizations using additive manufacturing report improved manufacturing flexibility, enabling them to respond quickly to changing market demands and customer preferences. Moreover, by using 3D printing for complex parts that typically require extensive tooling, businesses can streamline their supply chains and reduce lead times significantly.

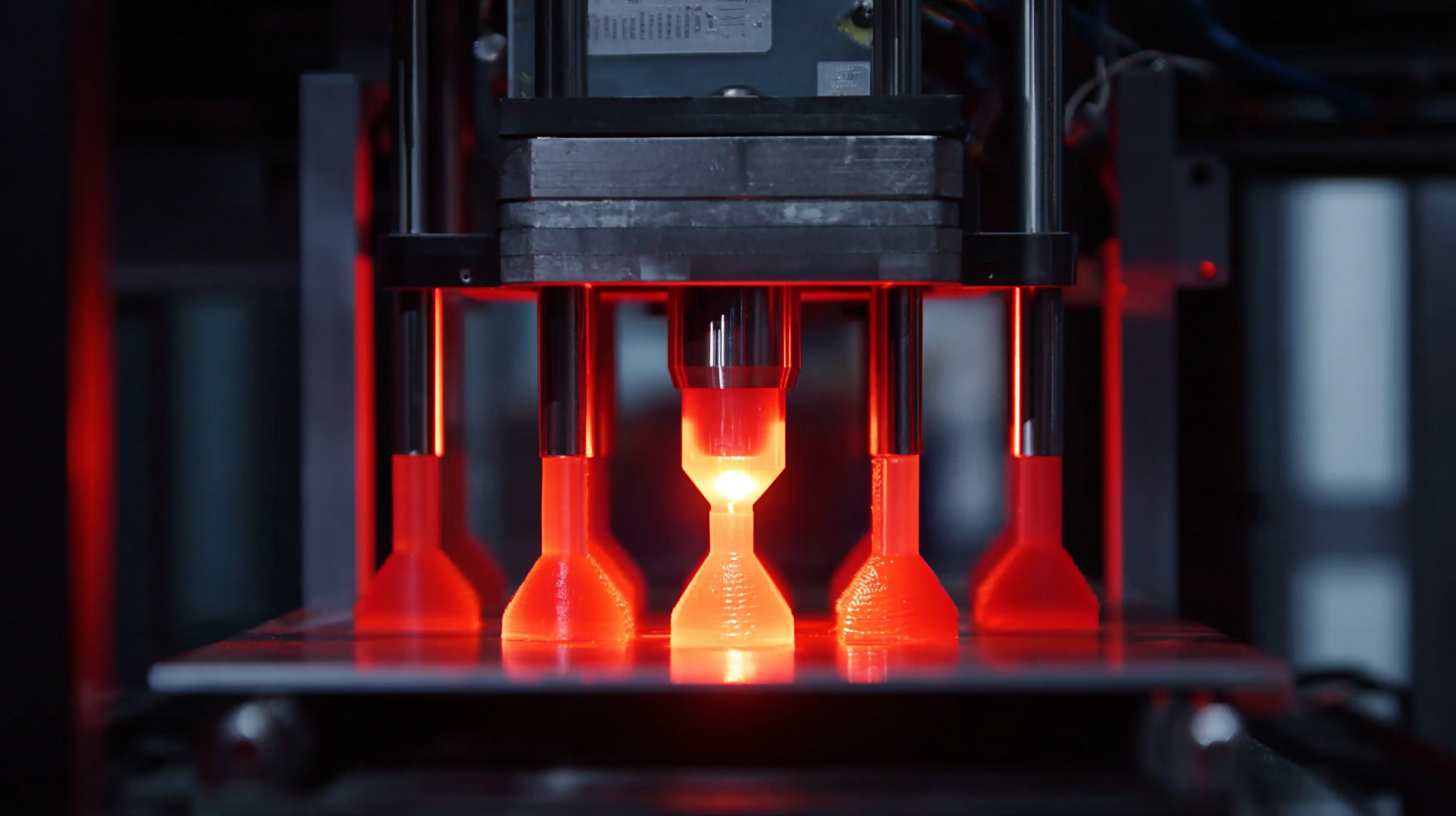

The adoption of 3D printing is transforming industries from aerospace to healthcare, where customized solutions can be fabricated on-demand. For instance, the medical sector has seen a 3D-printed prosthetic limb market that is expected to grow significantly, with an anticipated CAGR of 28.3% from 2020 to 2027 according to Grand View Research. This technological advancement not only boosts operational performance but also fosters a culture of continuous innovation, leading to more tailored solutions in various sectors.

Enhancing Customization and Personalization in Products

With the rise of commercial 3D printers, businesses are entering a new era of customization and personalization in product development. This innovative technology allows companies to tailor their offerings to meet the specific needs and preferences of their customers, ultimately enhancing consumer satisfaction and loyalty. By utilizing 3D printing, manufacturers can create unique designs that stand out in a competitive market, setting themselves apart from those relying on traditional mass production methods.

One valuable tip for businesses looking to enhance customization is to engage customers in the design process. Solicit feedback on prototypes and encourage customers to share their ideas. This not only fosters a sense of connection but also helps create products that truly resonate with users. Additionally, leveraging software that allows for easy adjustments to digital designs can streamline the customization process, enabling quick modifications based on consumer input.

Another crucial aspect is the ability to produce low-volume, high-variability products at an affordable cost. This flexibility allows companies to experiment with different designs or limited-edition items without the significant financial risk associated with traditional manufacturing. By implementing a lean production approach, businesses can respond rapidly to market trends and consumer demands, ensuring they remain relevant and innovative in an ever-evolving landscape.

Reducing Costs and Waste Through Efficient Manufacturing

In today’s competitive landscape, businesses are constantly seeking ways to reduce costs and waste, and commercial 3D printers are emerging as a game-changing solution. By leveraging additive manufacturing techniques, companies can generate parts and products layer by layer, minimizing the raw materials required compared to traditional subtractive methods. This not only lowers production costs but also significantly decreases material wastage, allowing businesses to allocate resources more effectively.

Moreover, the customization capabilities of 3D printing enable businesses to produce specialized products on demand, further reducing inventory costs. Traditional manufacturing often leads to overproduction and surplus inventory, which can strain financial resources. With commercial 3D printers, companies can create exactly what they need, reducing excess stock and streamlining supply chains. This efficient manufacturing process not only enhances profitability but also contributes to a greener approach by cutting down on excess waste, thus aligning with sustainability goals that are increasingly important in the modern economy.

| Reason | Description | Impact on Business | Estimated Savings |

|---|---|---|---|

| Cost Reduction | Lower costs for materials by reducing waste in manufacturing. | Enhanced profitability and competitive pricing. | Up to 30% reduction in production costs. |

| Customization | Ability to produce tailored products meeting specific customer needs. | Increased customer satisfaction and loyalty. | Increased revenue potential by 20%. |

| Faster Prototyping | Accelerates the design process by allowing rapid prototyping. | Shorter time to market for new products. | Reduces R&D costs by 25%. |

| Material Efficiency | Utilizes additive manufacturing to minimize material use. | Reduced environmental impact and compliance with sustainability goals. | Saves up to 50% on material costs. |

| Innovation Opportunities | Enables the creation of designs that were previously impossible. | Encourages a culture of innovation within the organization. | Potential for new patents and products, increasing overall market share. |

Accelerating Prototyping and Product Development Cycles

In today's fast-paced market, businesses are increasingly turning to advanced technologies to accelerate their prototyping and product development cycles. One significant player in this transformation is commercial 3D printing, which enables teams to rapidly produce prototypes, allowing for quick iteration and feedback. This agility not only shortens development timelines but also enhances innovation by enabling companies to test multiple designs in parallel, leading to improved products and faster market entry.

Tip 1: Embrace an iterative design process facilitated by 3D printing. By continuously refining prototypes based on real-time feedback, teams can identify potential issues early, which reduces the overall cost of development.

The integration of advanced methodologies such as generative AI enhances this process even further. As AI technologies streamline design choices and automate mundane tasks, engineers can focus on creative problem-solving. This synergy between 3D printing and AI-driven solutions is poised to redefine how products evolve from concept to completion, fostering an environment of rapid innovation.

Tip 2: Invest in training your team on cutting-edge tools that integrate 3D printing with AI. This can unlock new opportunities for creativity and significantly improve your product's development efficiency.

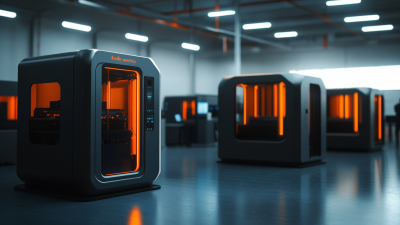

Enabling Innovative Designs and Complex Structures with 3D Printing

The advent of commercial 3D printers has revolutionized the way businesses approach design and manufacturing. One of the most compelling advantages of these advanced technologies is their ability to enable innovative designs and the creation of complex structures that were previously unattainable. According to a recent report by Wohlers Associates, the global 3D printing market is projected to reach $34.8 billion by 2024, underscoring the growing recognition of additive manufacturing's potential to drive efficiency and foster innovation across various industries.

3D printing opens doors to limitless design possibilities, allowing engineers and designers to create intricate geometries that traditional manufacturing methods cannot replicate. For instance, companies in aerospace and automotive industries are leveraging 3D printing to develop lightweight components that enhance performance while reducing material waste. A study by McKinsey & Company highlights that 3D printing can reduce time to market by up to 75%, significantly accelerating the development cycle for new products. This efficiency is crucial in an era where speed and adaptability are key competitive advantages.

Moreover, the flexibility offered by commercial 3D printers empowers businesses to quickly iterate on designs, enabling rapid prototyping and testing of new concepts. This capability not only fosters creativity but also helps in minimizing costs associated with failed designs. According to a survey by Deloitte, 30% of manufacturing executives cite faster product development and the ability to customize products as primary drivers for adopting 3D printing technologies. As businesses continue to explore the vast potential of 3D printing, the integration of these technologies will undoubtedly shape the future landscape of product design and manufacturing.

Related Posts

-

Ultimate Guide to Choosing the Best Carbon Fiber 3D Printer for Your Business Needs

-

Unlocking Innovation: Advantages of the Best 3D Printing Materials for Your Projects

-

Top 10 Commercial 3D Printer Manufacturers from China at the 137th Canton Fair

-

Unlocking the Secrets to Sourcing Top Tier 3D Printer Manufacturers for Global Buyers

-

Future of 3D Printing in 2025 Essential Trends and Actionable Checklist for Success

-

Finding Reliable Vendors for Large 3D Printers to Boost Your Manufacturing Efficiency