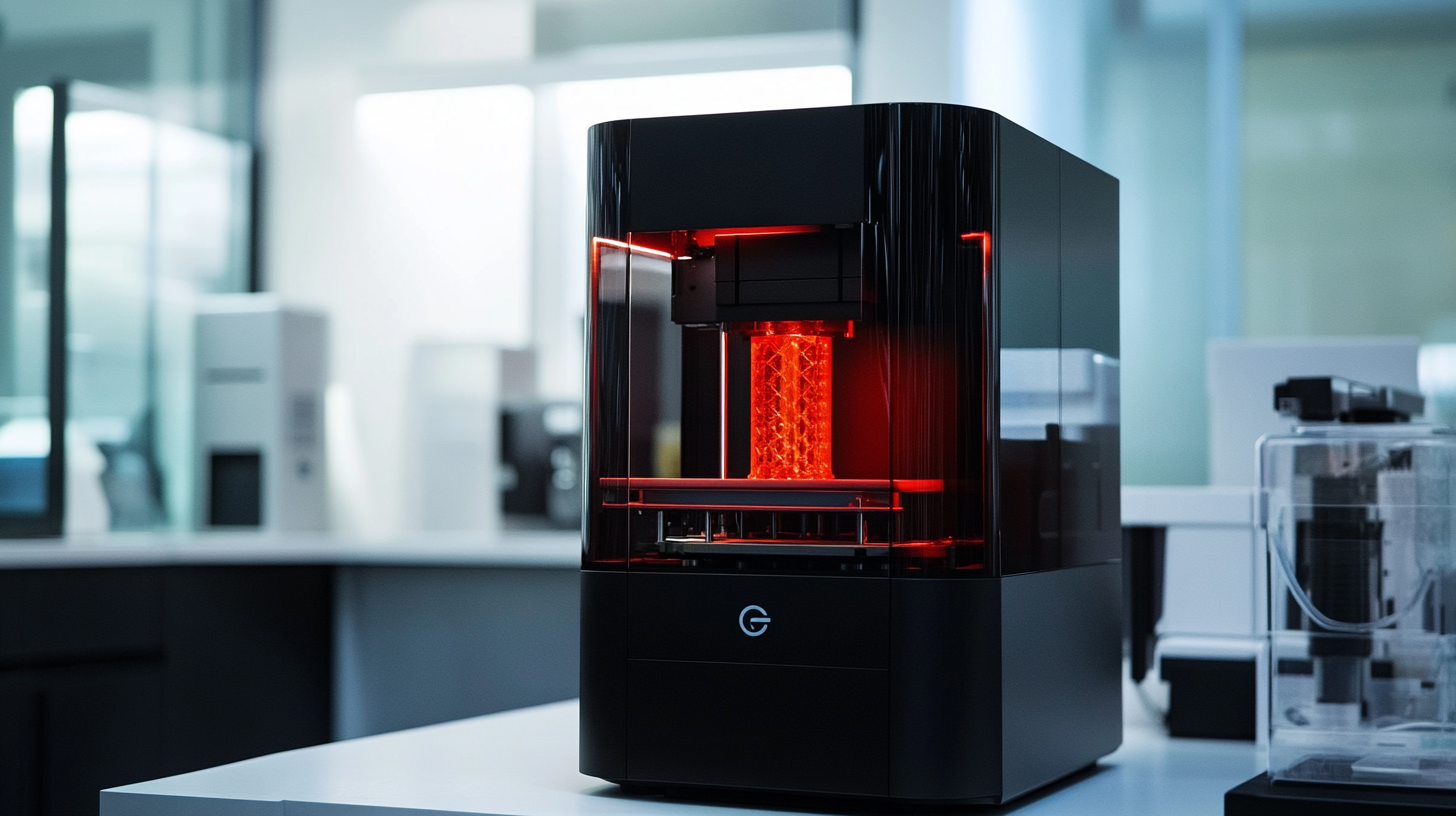

Leading the Charge: Explore the Superiority of China's Best Carbon 3D Printers for Global Buyers

In recent years, the global demand for innovative manufacturing technologies has surged, with the 3D printing industry projected to reach a staggering $34.8 billion by 2024, according to a report by MarketsandMarkets. Among the various technologies available, Carbon 3D printers have emerged as a frontrunner, particularly in China, where advancements in materials and processes have set new industry standards. The superior speed, precision, and material versatility of Carbon 3D printers allow manufacturers to produce complex geometries that were previously unattainable. With an increasing emphasis on sustainability and rapid prototyping, China’s leading Carbon 3D printer models are not only meeting domestic needs but are also positioning themselves as competitive options for global buyers. This blog will delve into the features, benefits, and leading solutions offered by China’s best Carbon 3D printers, demonstrating why they are becoming the preferred choice for innovative manufacturers worldwide.

Leading the Charge: China's Carbon 3D Printers Set to Dominate the Global Market

China is rapidly establishing itself as a powerhouse in the global carbon 3D printing market, poised to dominate with advancements in technology and manufacturing prowess. According to a recent report by MarketsandMarkets, the global 3D printing market is expected to grow from $13.7 billion in 2020 to $62.5 billion by 2026, with a significant portion of this growth driven by carbon technology applications. China's strategic investments in research and development, combined with an increasing number of patents filed in the carbon 3D printing space, underline its commitment to leading this booming sector.

Chinese manufacturers, such as Shenzhen Fabbro and Hunan Nanyuan, are at the forefront, offering carbon 3D printers that excel in speed, efficiency, and material capabilities. A study by Wohlers Associates highlights that the performance of these printers can result in a 40% reduction in material costs and a 50% decrease in production time compared to traditional manufacturing methods. With their ability to produce lightweight yet strong components, these printers are increasingly adopted across various industries, including aerospace, automotive, and healthcare, making them critical players in the global supply chain. As global buyers seek reliable and innovative solutions, China's carbon 3D printers are set not only to meet these demands but to influence the very landscape of additive manufacturing worldwide.

Leading the Charge: Comparison of Carbon 3D Printer Features

Unpacking the Advanced Technology Behind Top Chinese Carbon 3D Printers

Exploring the advanced technology behind China's best carbon 3D printers reveals a landscape filled with innovation and precision. These printers leverage cutting-edge materials and sophisticated engineering techniques to deliver exceptional quality and reliability. By utilizing carbon fiber composites, they achieve lightweight yet incredibly durable parts, making them suitable for a variety of industries, from aerospace to automotive.

Tips for choosing the right carbon 3D printer include evaluating the machine's build volume, print speed, and material compatibility. Consider how often you'll be using the printer and for what types of projects, as these factors can greatly influence your choice. Additionally, look for printers that offer easy maintenance and support, ensuring a smoother operation over time.

Another important aspect is the printer's software capabilities. Advanced slicing software can enhance print quality and optimize material usage, resulting in cost savings and improved efficiency. Familiarizing yourself with different software options can significantly impact your printing experience, so it’s worth researching which features are most beneficial for your specific needs.

Market Trends: China's Growing Share in the Global 3D Printing Industry

As global market dynamics shift, China's dominance in the 3D printing industry is becoming increasingly apparent. The market is witnessing an impressive growth trajectory, with the dental 3D printing sector projected to exceed $3 billion by 2023. From 2024 to 2032, this segment is expected to grow at a remarkable compound annual growth rate (CAGR) of around 21.5%. This surge is primarily driven by an enhanced focus on reducing turnaround times and minimizing material waste in dental laboratories, prompting a shift towards more efficient production methods.

Moreover, the broader landscape of Industry 4.0 is showing promising potential, with the global market anticipated to expand from $130.9 billion in 2022 to an estimated $377.33 billion by 2029. This represents a CAGR of 16.3%, highlighting the growing adoption of advanced technologies, including 3D printing, across various sectors. Within this context, China is poised to play a critical role, providing cutting-edge carbon 3D printers that cater to an international audience eager for innovation and efficiency. As market trends evolve, global buyers are increasingly recognizing the value of integrating Chinese technology into their production processes.

Comparative Analysis: Performance Metrics of China's Carbon 3D Printers vs. World Leaders

In recent years, China's carbon 3D printers have made substantial strides in terms of performance and reliability, positioning themselves as formidable competitors to globally recognized brands. According to a report by Wohlers Associates, China's share of the 3D printing market grew to 23% in 2022, with significant advancements in resin technology and printer speed. Comparative analysis shows that models such as the Anycubic Photon Mono X and the Elegoo Mars 3 outperform many imports in terms of build volume and print resolution, with a layer resolution of up to 0.01 mm and print speeds of up to 100 mm/h.

Additionally, industry-specific tests reveal that China's leading carbon 3D printers exhibit a heat-resistant performance of over 300 degrees Celsius and demonstrate flexibility exceeding 17,000 PSI. This places them in a competitive realm against established brands like Formlabs and Stratasys, which report similar thermal properties but at significantly higher price points. As global buyers seek cost-efficient yet high-performance options, China's 3D printers are not only capturing market interest but are also setting new benchmarks for capability and innovation in the additive manufacturing landscape.

Buyer Insights: Key Considerations When Choosing a Chinese Carbon 3D Printer

The market for carbon 3D printers in China has witnessed significant growth, driven by innovations and the rising demand for high-quality manufacturing solutions. As outlined in the recent McKinsey report on consumer trends, the rapid evolution of technology within various sectors, including automotive, necessitates that Original Equipment Manufacturers (OEMs) adapt quickly to maintain competitive advantages. For global buyers, understanding the specific features that distinguish Chinese carbon 3D printers is crucial.

When selecting a Chinese carbon 3D printer, there are several key considerations to keep in mind. First, the precision and reliability of printing technology are paramount. Reports indicate that leading Chinese manufacturers are producing printers with layer resolutions as low as 25 microns, significantly enhancing the quality of intricate designs. Additionally, the materials compatibility offered by these printers is expanding, ensuring that they can handle diverse printing needs, from prototyping to final parts production. Buyers should also consider the after-sale service and support, which are essential for maximizing the performance and longevity of these sophisticated machines. The continuous advancements in this field highlight why it is advantageous for global buyers to explore the superior offerings from China.