Exploring the Future of Manufacturing: How Large 3D Printers Are Revolutionizing Industry

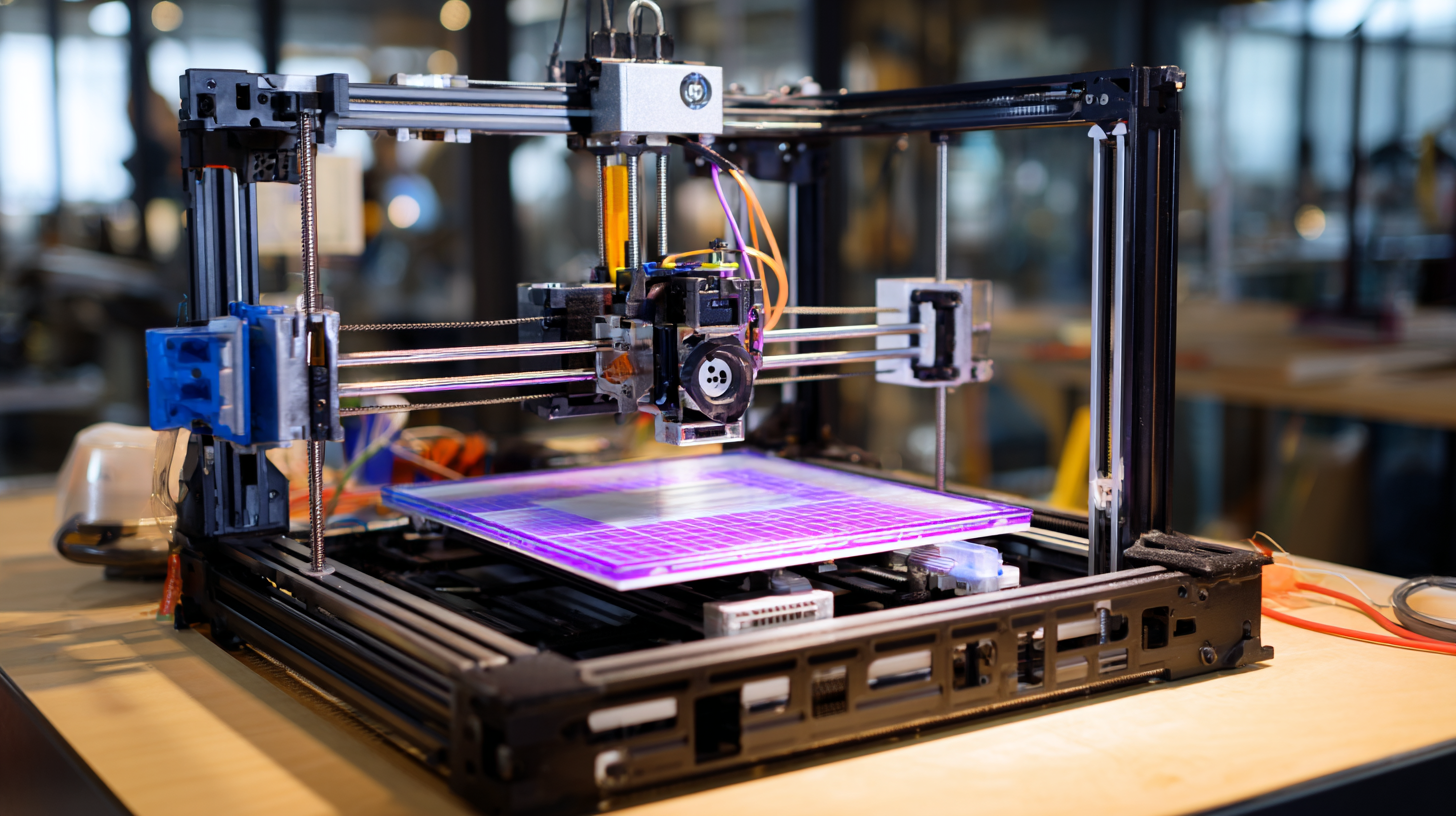

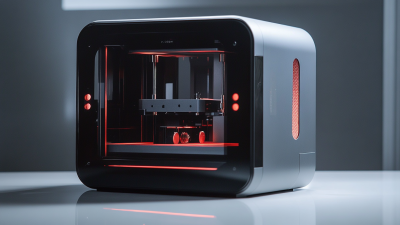

The future of manufacturing is witnessing a transformative shift, largely driven by the advent of

large 3D printers, which are redefining traditional production paradigms. These innovative machines have the potential to create complex geometries and custom parts with

unprecedented speed and accuracy, revolutionizing industries from aerospace to automotive.

Large 3D printers not only enhance efficiency and reduce waste but also enable manufacturers to decentralize production, allowing for

on-demand manufacturing that minimizes inventory costs. As companies increasingly embrace this technology, they are positioned to meet the changing demands of consumers who seek

personalized and sustainable products. The exploration of large 3D printer capabilities paves the way for a new era in manufacturing, where creativity and

efficiency can go hand in hand, setting the stage for a reimagined industrial landscape.

Large 3D printers not only enhance efficiency and reduce waste but also enable manufacturers to decentralize production, allowing for

on-demand manufacturing that minimizes inventory costs. As companies increasingly embrace this technology, they are positioned to meet the changing demands of consumers who seek

personalized and sustainable products. The exploration of large 3D printer capabilities paves the way for a new era in manufacturing, where creativity and

efficiency can go hand in hand, setting the stage for a reimagined industrial landscape.

How Large 3D Printers Are Transforming Supply Chain Dynamics in Manufacturing

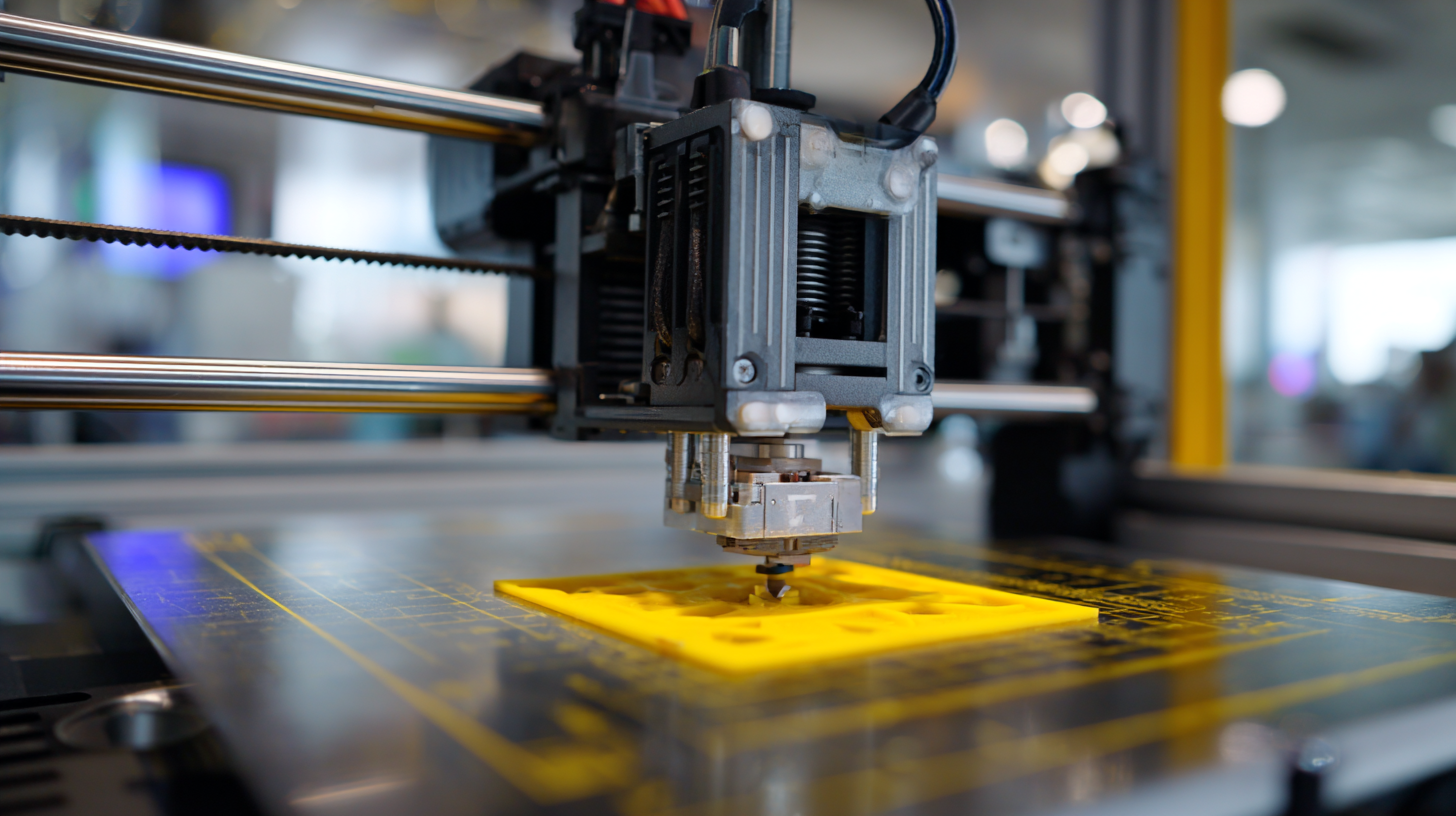

Large 3D printers are significantly transforming supply chain dynamics in manufacturing by enabling on-demand production and reducing lead times. Traditional manufacturing often relies on bulk production, leading to excess inventory and increased storage costs. In contrast, large 3D printers allow companies to print components as needed, thus minimizing overproduction and streamlining inventory management. This shift not only drives cost efficiency but also enhances flexibility in product design and customization.

**Tips:** To fully leverage large 3D printing technology, manufacturers should invest in training their workforce. Understanding how to operate and maintain 3D printers effectively is crucial for maximizing productivity. Additionally, integrating 3D printing into existing supply chains requires a comprehensive analysis of current processes to identify areas where this technology can add value.

By embracing large 3D printing, manufacturers can anticipate shifts in consumer demand more accurately and respond to market changes swiftly. This agility contributes to a more resilient supply chain, allowing businesses to innovate and stay competitive in an evolving landscape.

**Tips:** Collaborating with technology providers and participating in industry forums can offer insights into best practices and emerging trends in 3D printing. Establishing partnerships can also facilitate knowledge sharing, driving further innovations in manufacturing processes.

Key Industries Adopting Large 3D Printing Technologies for Competitive Advantage

As industries strive for innovation and efficiency, large 3D printing technologies are becoming pivotal in sectors such as aerospace, automotive, and healthcare. Companies are increasingly adopting these advanced manufacturing techniques to enhance their production capabilities, streamline processes, and minimize costs. For instance, in aerospace, manufacturers use large 3D printers to create lightweight components that not only reduce fuel consumption but also improve overall performance. Similarly, the automotive industry leverages these technologies for rapid prototyping and production of custom parts, allowing for faster design iterations and enhanced vehicle personalization.

Tips: When considering the adoption of large 3D printing, assess your current manufacturing processes to identify areas for improvement. Investing in training for your team can also maximize the benefits of this technology, as skilled personnel will be key in leveraging its full potential.

Another key area is healthcare, where large 3D printers are revolutionizing the way medical devices and prosthetics are produced. Customization is a notable advantage, as doctors can tailor solutions to individual patient needs more effectively. By utilizing these technologies, healthcare providers can not only speed up the production of necessary items but also create solutions that improve patient outcomes.

Tips: Explore partnerships with tech firms specializing in large 3D printing to stay ahead of the curve. Attending industry conferences can also provide insights into emerging trends and innovations, further enhancing your competitive edge.

The Economic Impact of 3D Printing on Manufacturing Cost Efficiency and Waste Reduction

The economic impact of 3D printing on manufacturing cost efficiency and waste reduction is becoming increasingly significant as industries adapt to these innovative technologies. With the growth of large 3D printers, manufacturers can streamline their processes, reducing production costs and minimizing material waste. This is particularly evident in sectors like aerospace and automotive, where the precision of additive manufacturing allows for the creation of complex components that were once difficult to produce, thereby optimizing the supply chain and shortening lead times.

Furthermore, the adoption of sustainable materials in construction, such as eco-friendly 3D printed bricks, illustrates how waste can be repurposed into valuable resources. As companies venture into using biodegradable or recycled materials for building, they contribute to a circular economy that not only decreases environmental impact but also enhances energy efficiency. The projected growth in markets like aluminum powder and precast concrete highlights the broader shift towards more resource-efficient manufacturing practices, underscoring the transformative role of 3D printing in shaping a sustainable industrial landscape.

Future Predictions: Market Growth and Technological Advancements in 3D Printing

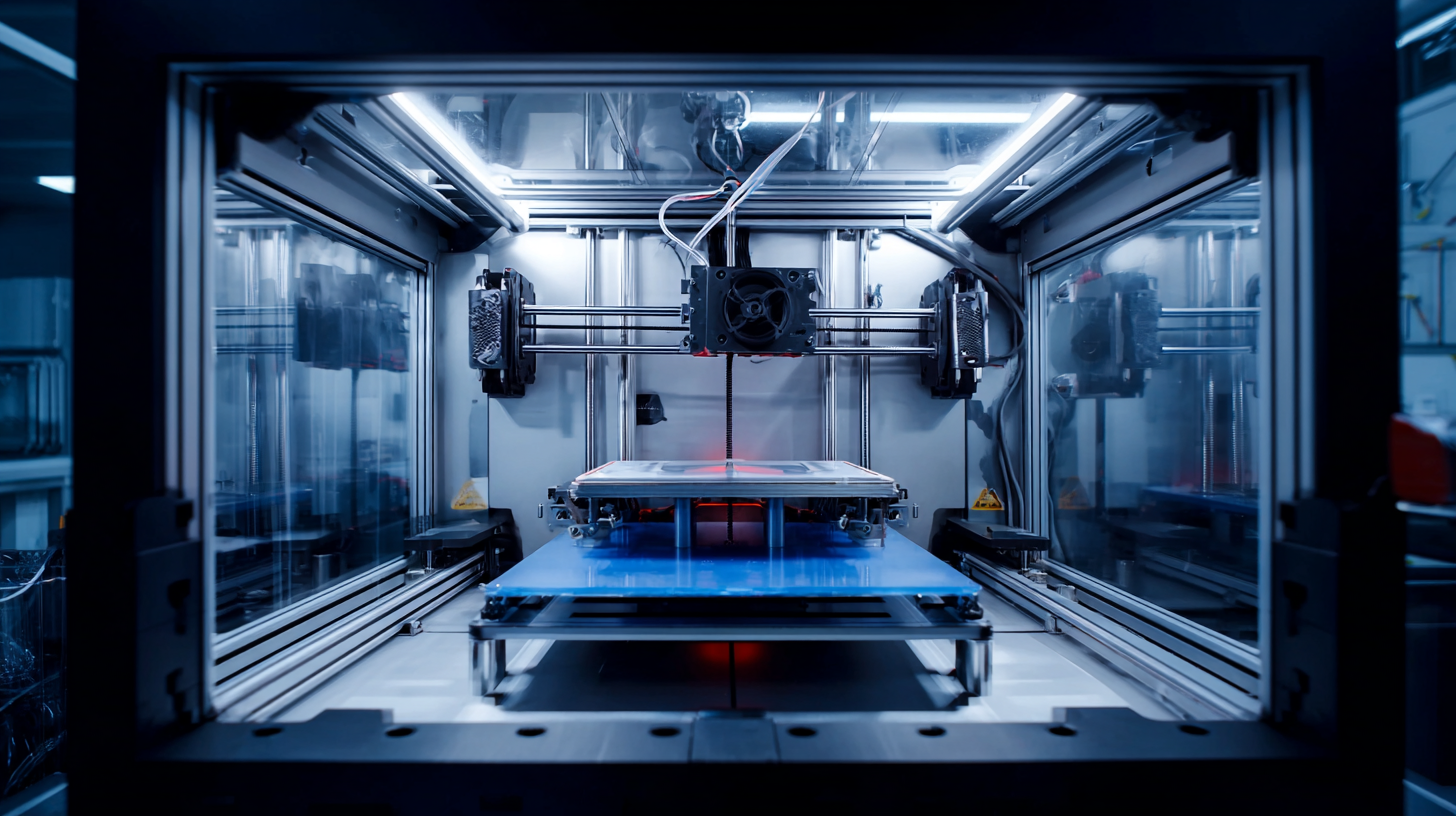

The future of manufacturing is being significantly reshaped by the advancements in large 3D printing technology. As industries increasingly adopt this innovation, predictions for market growth indicate an exponential rise in its application across various sectors. Analysts forecast that the global 3D printing market could surpass $50 billion by 2026, driven by demand for rapid prototyping, customized production, and decreased operational costs. Industries such as aerospace, automotive, and healthcare are expected to lead this surge, leveraging 3D printing to create complex components with reduced material waste and shorter lead times.

Technological advancements are also paving the way for more versatile and efficient printing methods. Developments in materials science, such as the introduction of high-performance polymers and metals, allow for stronger and lighter products that meet rigorous industry standards. Furthermore, innovations in print speed and multi-material printing are heightening productivity levels, enabling manufacturers to push the boundaries of design and function. As these trends evolve, we can anticipate a more interconnected and automated manufacturing landscape, where large 3D printers play a central role in creating the next generation of products tailored to the specific needs of consumers and industries alike.

Case Studies: Successful Implementations of Large 3D Printers in Industrial Settings

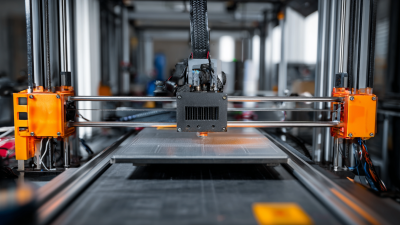

Large 3D printers are increasingly becoming a game changer in various industrial settings, as evidenced by several successful case studies. One prominent example is Boeing, which has integrated large-scale 3D printing to manufacture components for its aircraft. The aerospace giant reported that using 3D printing for parts like brackets and fixtures has reduced production costs by up to 90%, while streamlining lead times significantly. With advanced additive manufacturing techniques, Boeing aims to enhance its production efficiency and tackle the challenges of decreasing traditional manufacturing capabilities.

Another notable case comes from General Electric (GE), which is leveraging large 3D printers to produce gas turbine components. GE has noted that through the use of 3D printing, the weight of certain turbine parts has been reduced by 25%, which not only saves on material costs but also improves fuel efficiency in their engines. According to a report by Gartner, the global 3D printing market in manufacturing is expected to reach $38.2 billion by 2025, highlighting the transformative impact of technologies like large 3D printers in industrial production lines. These implementations are paving the way for more agile and cost-effective manufacturing processes across various sectors.

Related Posts

-

10 Essential Features of the Best Large 3D Printers for Global Buyers

-

How to Maximize Efficiency with a Large 3D Printer in Your Business

-

Unlocking the Secrets to Sourcing Top Tier 3D Printer Manufacturers for Global Buyers

-

Top 10 Commercial 3D Printer Manufacturers from China at the 137th Canton Fair

-

How to Choose the Right Professional 3D Printer for Your Business Needs

-

Understanding Industry Standards for Choosing the Best Fast 3D Printer for Your Business Needs