2026 How to Choose Electric Ball Valves for Your Projects?

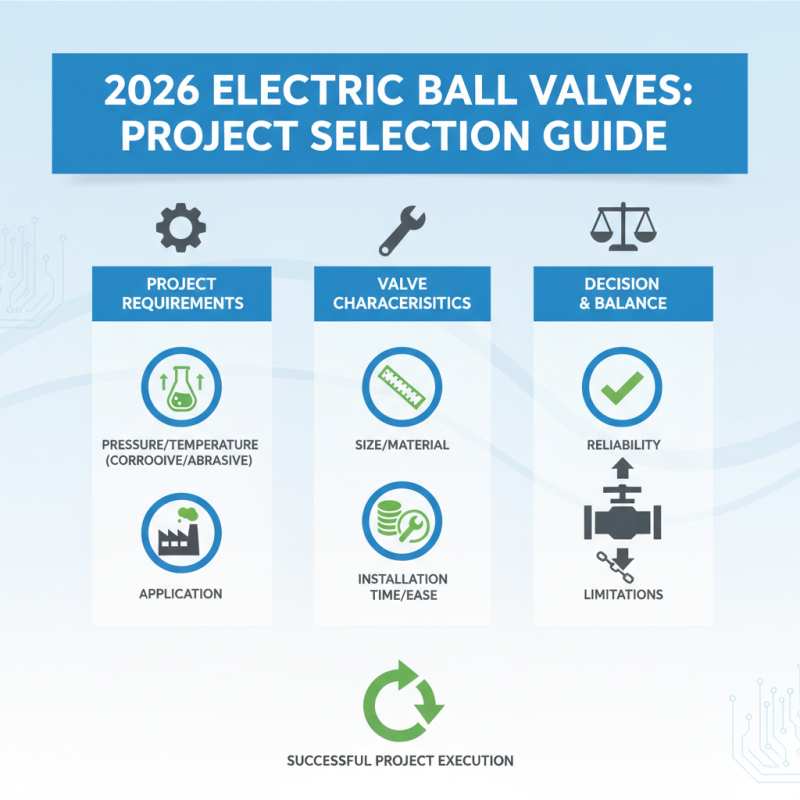

Choosing the right Electric Ball Valves for your projects can be a complex task. These valves are essential components in many systems. They control fluid flow effectively and offer reliability. However, selecting the best options requires careful consideration.

Electric Ball Valves come in various sizes and materials. Understanding your project’s requirements is crucial. Are you working with high pressure? Is the fluid corrosive? These questions matter. You may have a specific application in mind. But not all valves are created equal. Some may not be suited for your needs.

While many options exist, not every choice is perfect. You might find valves that are too costly or those that take too long to install. Finding the right balance can be challenging. Recognizing both advantages and limitations of Electric Ball Valves is essential for successful project execution.

Understanding Electric Ball Valves: Basics and Functionality

Electric ball valves have become a popular choice in various industries. They provide efficient flow control and are easy to automate. Understanding how they work is essential for making informed decisions on projects. Typically, these valves consist of a spherical disc that controls flow. A motor drives the ball to open or close the valve.

In a recent industry report, it was noted that the global electric valve market is expected to reach approximately $6 billion by 2025. This growth reflects the increasing reliance on automation in engineering. Electric ball valves are not just easy to install but also low-maintenance. Yet, users should consider factors such as power supply and control methods. Some projects might encounter challenges due to incompatible systems or fluctuating power sources.

Moreover, assessing the specific requirements of your project is crucial. Unique factors such as pressure rating and fluid type can influence performance. An electric ball valve that works well in one setting may perform poorly in another. Developers often overlook these nuances, leading to operational inefficiencies. Certain environments may also require additional protective measures to maintain valve integrity. The right choice can significantly impact system reliability and longevity.

Key Factors to Consider When Choosing Electric Ball Valves

When choosing electric ball valves, several key factors come into play. First, consider the valve size. It should match your pipe diameter perfectly. A mismatch can lead to flow issues. Then, think about the pressure rating. Ensure it can handle your system's demands. Underestimating pressure can cause failures.

Next, look at the control method. Electric actuators offer precise control. Some may prefer manual adjustments. Evaluate your project needs carefully. Don't overlook the material of the valve. Corrosion resistance is vital for longevity. Using unsuitable materials can result in quick deterioration.

Lastly, consider installation requirements. Some valves are easier to install than others. Complex installations can increase project costs. Reflect on your team's skills and time available. These factors will impact your overall project timeline. Careful consideration now can save time and money later.

2026 How to Choose Electric Ball Valves for Your Projects?

This chart illustrates the key factors to consider when choosing electric ball valves for your projects, highlighting the importance of each criterion based on survey results from industry professionals.

Evaluating Specifications: Size, Pressure, and Voltage Requirements

When choosing electric ball valves for your projects, evaluating specifications is crucial. Start with size. The valve must fit your pipe system perfectly. Check both dimensions and mounting options. A mismatched size can lead to leaks or installation challenges.

Next, consider pressure requirements. Every system has a specific pressure range. Ensure the valve can handle these pressures without failing. A valve rated too low may cause serious issues. Evaluating pressure helps prevent costly damages and repairs later.

Voltage requirements also play a role. Make sure the electrical specifications align with your control systems. Mismatched voltage can lead to valve malfunction or even failure. Understanding these electrical needs is essential for smooth operation. Always double-check these details to avoid mistakes that could have significant impacts on your system's performance.

Material Selection for Enhanced Durability in Electric Ball Valves

Choosing the right materials for electric ball valves is crucial. Durability can directly impact your project’s success. Common materials include stainless steel, brass, and plastic. Each has unique properties suited for different applications. Stainless steel is robust but may be more expensive. On the other hand, plastic is lightweight and cost-effective but can wear out quicker.

Consider the operating environment. High temperatures or chemicals can degrade certain materials. If the valve is exposed to harsh conditions, opt for high-grade materials. It's essential to reflect on the long-term implications of your choice. Cost savings now could lead to more frequent replacements later.

Tip: Always check for compatibility with the fluid you are handling. This ensures the valve functions properly over time. Another tip is to assess the valve's mechanical properties. Ensure it can withstand your project's demands. Durability is not just about initial costs but about the lifespan and reliability of your valves.

2026 How to Choose Electric Ball Valves for Your Projects? - Material Selection for Enhanced Durability in Electric Ball Valves

| Material Type | Temperature Range (°C) | Pressure Rating (Bar) | Corrosion Resistance | Applications |

|---|---|---|---|---|

| Stainless Steel | -40 to 200 | 16 | High | Oil & Gas, Water Treatment |

| PVC | 0 to 60 | 10 | Moderate | Chemical Processing, HVAC |

| Bronze | -30 to 130 | 12 | High | Marine, Water Supply |

| Carbon Steel | -29 to 400 | 20 | Moderate | Oil, Natural Gas |

| PTFE (Teflon) | -200 to 260 | 8 | Very High | Pharmaceuticals, Food Processing |

Best Practices for Installation and Maintenance of Electric Ball Valves

When installing electric ball valves, proper planning is crucial. First, consider the flow direction. Ensure that the valve aligns with the pipeline layout. Misalignment can lead to operational issues. Remember to check the actuator's power requirements. A mismatch could cause failure.

During installation, attention to sealing is vital. Loose seals can lead to leaks. Inspect all connections carefully. Pay close attention to the mounting position of the valve. It should not be under excessive pressure or strain. Taking time with these details can prevent future complications.

Regular maintenance is equally important. Schedule routine inspections to check for wear. Corrosion can undermine performance. Ensure the actuator is functioning smoothly. If any irregular noises are heard, address them promptly. It's easy to overlook small issues until they become larger problems. Taking a proactive approach can save time and costs later.