How to Maximize Efficiency with a Large 3D Printer in Your Business

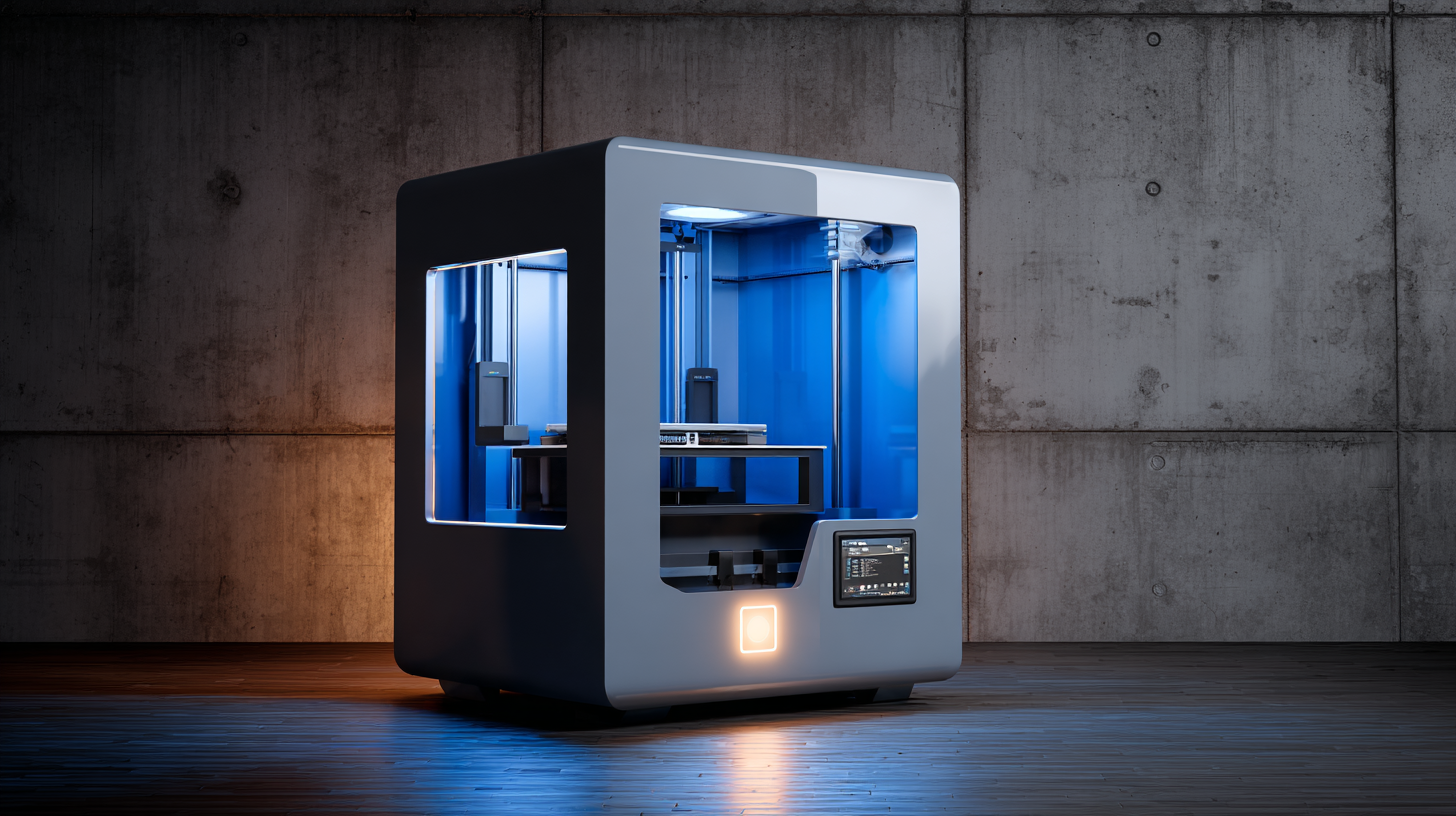

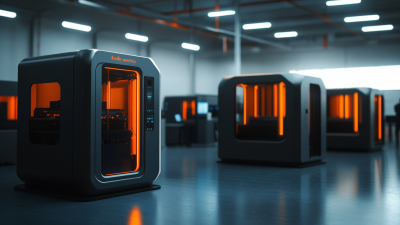

In today's competitive business landscape, harnessing advanced technologies is crucial for maximizing efficiency and maintaining a competitive edge. One such innovative solution is the Large 3D Printer, a powerful tool that can revolutionize production processes across various industries. By enabling rapid prototyping, custom manufacturing, and reduced material waste, a Large 3D Printer can significantly streamline operations and enhance productivity. However, to truly reap the benefits of this technology, businesses must implement strategic practices tailored to their specific needs and workflows. In this blog, we will explore effective strategies and tips on how to maximize the efficiency of a Large 3D Printer within your business, ensuring you can fully leverage its capabilities to drive innovation and growth.

Understanding the Benefits of Large 3D Printers for Business Operations

Large 3D printers are rapidly transforming the operational landscape for businesses across various industries. One of the primary benefits of adopting this technology is the remarkable efficiency gains it offers. With the capability to produce large-scale components in a single print, organizations can drastically reduce lead times and minimize the need for assembly, which not only saves time but also cuts down on labor costs. This streamlined production approach allows businesses to meet demand rapidly without compromising on quality.

Moreover, large 3D printers enable customization at an unprecedented level. Companies can create tailored products that cater to specific customer needs, enhancing customer satisfaction and loyalty. The technology allows for iterative designing, so businesses can quickly modify products based on feedback or emerging trends. This agility not only keeps companies competitive but also fosters innovation, giving them a significant edge in the fast-paced market. By integrating large 3D printing into their operations, businesses can harness both efficiency and customization, positioning themselves for sustained success.

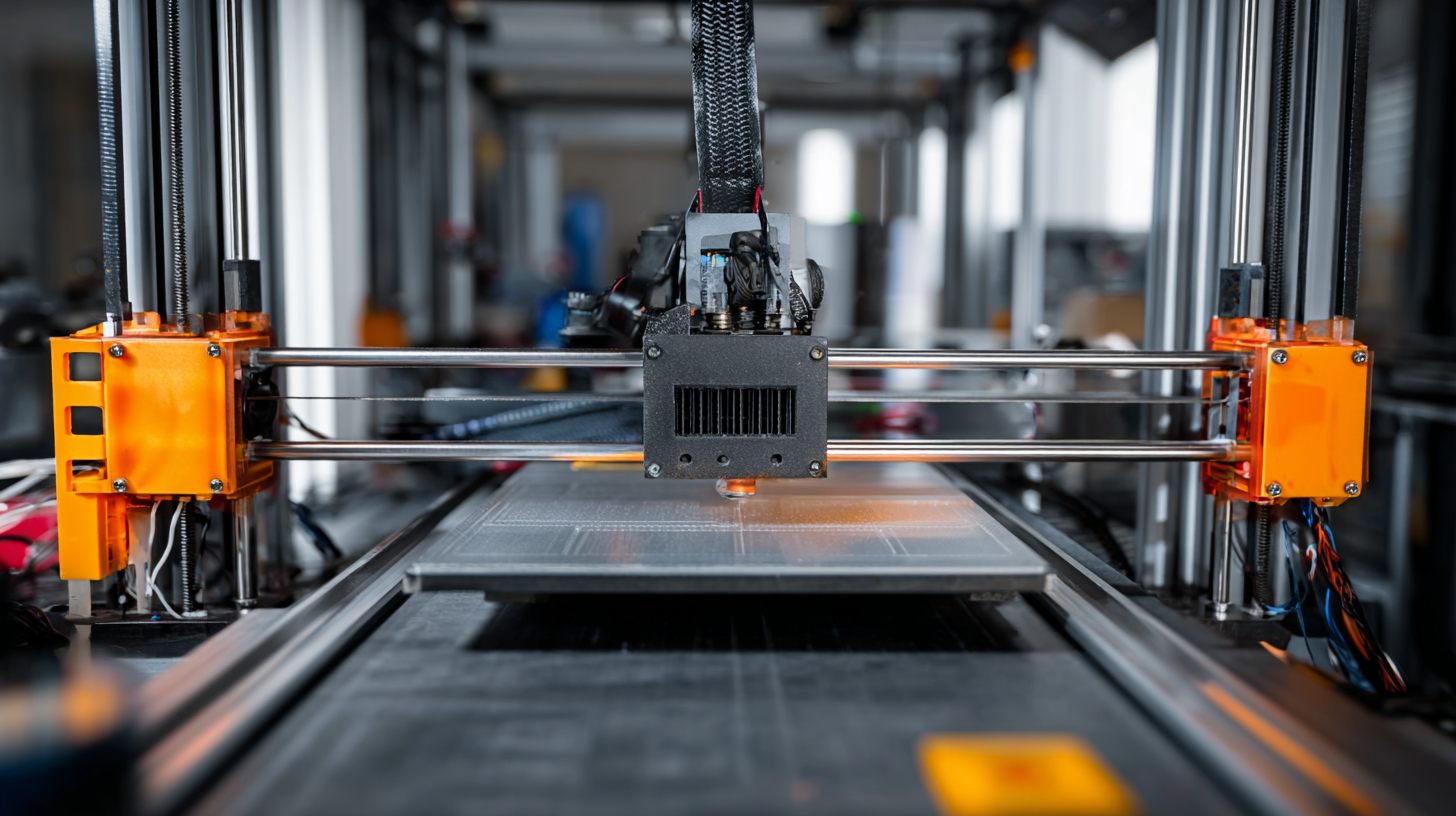

Key Features to Look for in a Large 3D Printer

When considering a large 3D printer for your business, it's essential to focus on several key features that can significantly enhance efficiency and productivity. One of the primary characteristics to look for is build volume. A larger build area allows for more complex and larger components to be printed in a single run, reducing the need for multiple setups and assembly time. This is particularly beneficial for industries that require prototyping and production of sizable parts, such as automotive or aerospace.

Another critical feature is print speed. In a fast-paced business environment, the ability to produce high-quality prints quickly can set you apart from competitors. Look for printers with advanced extrusion systems that can handle high flow rates while maintaining precision. Additionally, consider the material versatility of the printer. A machine that supports a wide range of filaments, including strong thermoplastics and flexible materials, provides the flexibility needed to tackle various projects and customer needs. These features combined can significantly contribute to maximizing overall efficiency and streamlining production processes in your business.

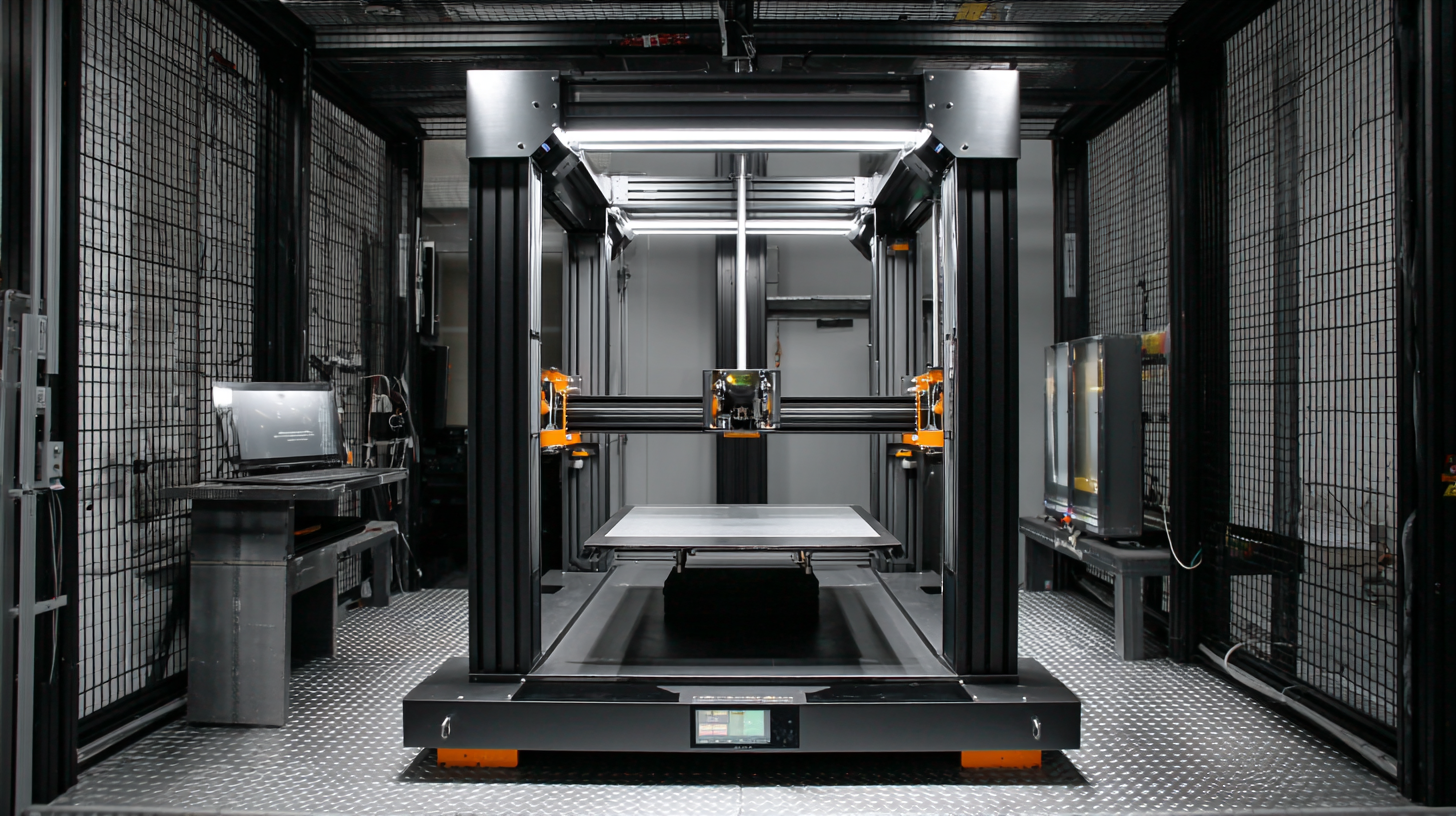

Strategies to Optimize Workflow with Large Scale 3D Printing

To optimize workflow with large-scale 3D printing, businesses should first focus on integrating specialized software that streamlines the design-to-production process. By utilizing advanced slicing software, companies can enhance print job management and reduce downtime. Features such as automated print queueing and real-time monitoring enable efficient scheduling and resource allocation, ensuring that the printer is always in use. Employing tools that facilitate collaboration among design teams can also minimize errors and maintain a consistent quality standard throughout the production cycle.

Additionally, maintaining a structured maintenance schedule for the 3D printer is crucial. Regular check-ups not only prevent unexpected breakdowns but also keep the machine operating at peak performance. Companies should train staff in preventative maintenance practices and troubleshooting techniques to swiftly address minor issues before they escalate. Establishing a routine for material inventory management can further reduce workflow interruptions, assuring that necessary supplies are always available when needed, thus leading to smoother operations and increased productivity.

Cost-Benefit Analysis: Investing in a Large 3D Printer for Your Business

Investing in a large 3D printer can transform the operational dynamics of a business, particularly in sectors like manufacturing and prototyping. According to a report by Wohlers Associates, the 3D printing industry reached a market size of $12.6 billion in 2020, with projections estimating it will grow to over $35 billion by 2024. This rapid growth underscores the increasing reliance on additive manufacturing technologies to enhance production capabilities and reduce costs.

A cost-benefit analysis reveals that the upfront expense of a large 3D printer can be offset by significant long-term savings. For instance, by using 3D printing for prototyping, companies can reduce material waste by up to 90% compared to traditional manufacturing processes, as reported by the American National Standards Institute. Additionally, the ability to quickly iterate designs can lead to faster time-to-market, which is critical in competitive industries.

By investing in a large 3D printer, businesses not only improve their efficiency but also position themselves to capitalize on future trends in mass customization and complex geometries.

Real-World Case Studies: Successful Implementation of Large 3D Printers

In the realm of manufacturing, large 3D printers are revolutionizing production lines by delivering unprecedented efficiency and creativity. Businesses such as aerospace and automotive have successfully implemented these advanced machines to scale their operations. For instance, a leading aerospace company utilized a large-format 3D printer to create complex engine components that were lighter yet equally durable. This innovation not only shortened the production time from weeks to days but also significantly reduced material waste, demonstrating how 3D printing can streamline operations and enhance sustainability.

Another compelling case comes from the construction industry, where a prominent firm used large 3D printers to construct housing structures. By adopting additive manufacturing techniques, they were able to fabricate entire walls in just hours, minimizing labor costs and accelerating project timelines. This approach also allows for greater design flexibility, enabling unique architectural solutions that traditional methods cannot achieve. Such real-world examples highlight the transformative potential of large 3D printing technologies, showcasing their ability to optimize both efficiency and creativity in various business sectors.

Efficiency Gains from Large 3D Printers in Businesses

This chart illustrates the percentage improvement in efficiency across various industries after implementing large 3D printers. The data reflects real-world applications and showcases how different sectors have benefited from these advanced manufacturing technologies.

Related Posts

-

Unlocking the Secrets to Sourcing Top Tier 3D Printer Manufacturers for Global Buyers

-

10 Essential Features of the Best Large 3D Printers for Global Buyers

-

Finding Reliable Vendors for Large 3D Printers to Boost Your Manufacturing Efficiency

-

How to Choose the Right Professional 3D Printer for Your Business Needs

-

Innovative Approaches for Global Buyers of 3D Printing Technology

-

Exploring Opportunities in Large Format 3D Printing: Highlights from the 137th Canton Fair