5 Digital Tips for Maximizing Efficiency with Your Carbon 3D Printer

As the manufacturing landscape continues to evolve, the importance of efficient production processes becomes increasingly vital. According to a report by Grand View Research, the global 3D printing market is expected to reach $44.2 billion by 2026, driven in part by advancements in technologies like the Carbon 3D printer. This innovative machine allows for unprecedented agility in design and production, significantly reducing lead times and material waste. With its capabilities to produce high-quality parts at an impressive speed, the Carbon 3D printer is positioning itself as an essential tool for businesses looking to enhance efficiency and sustainability. In this guide, we will explore five digital tips to help you maximize the effectiveness of your Carbon 3D printer, ultimately streamlining your workflow and elevating your production capabilities.

Maximizing Print Speed: Choosing the Right Settings for Your Carbon 3D Printer

When it comes to maximizing print speed with your Carbon 3D printer, selecting the right settings is crucial. Research indicates that parameters such as nozzle temperature, printing speed, layer height, and infill density play significant roles in optimizing performance. For instance, studies focused on PETG and PLA materials highlight how adjusting printing speed and infill can directly influence the mechanical properties, including tensile strength. By fine-tuning these aspects, users can achieve not only faster prints but also enhance the durability and functionality of their finished products.

Additionally, leveraging techniques like the Taguchi method can provide insights into how variations in layer thickness and wall structure affect overall print quality. For instance, maintaining an ideal layer height while carefully controlling the infill density can lead to improved mechanical testing outcomes. As reported, the combined optimization of these parameters enables print speeds that outperform many existing benchmarks in the market, allowing users to efficiently produce high-quality 3D printed parts without compromising on strength or structural integrity.

Optimizing Material Usage: Tips for Reducing Waste in 3D Printing Projects

In the realm of 3D printing, optimizing material usage is paramount to reducing waste and fostering sustainability. Recent studies highlight that effective material management can lead to up to 30% reduction in raw material consumption in additive manufacturing processes. With advancements in technology, new strategies for minimizing excess material during printing are emerging, including the use of advanced algorithms and AI to predict and adjust material requirements more accurately.

Moreover, as the construction industry increasingly adopts 3D printing, the shift towards sustainable practices is becoming evident. A report indicates that implementing sustainable additive manufacturing could reduce greenhouse gas emissions by as much as 50% in construction projects. By leveraging innovative production methods and sustainable materials, companies are not only cutting costs but also contributing to a greener future. The incorporation of AI in this sector is further enhancing efficiencies, allowing for real-time monitoring and adjustments that significantly curtail waste. Such integration is key to meeting the rising demands for eco-friendly building solutions while maintaining productivity and sustainability in construction.

Leveraging Software Tools: Enhancing Workflow Efficiency with Digital Solutions

Leveraging software tools is essential for enhancing workflow efficiency with your Carbon 3D printer. One effective tip is to utilize slicing software that is optimized for the specific capabilities of your printer. This software can significantly reduce print time and material waste by allowing you to customize settings for different projects, ensuring that each print is as efficient as possible. Adjusting parameters such as layer height, infill density, and print speed can lead to improved quality and faster turnaround times.

Another key aspect is integrating project management tools that facilitate communication and task tracking among team members. By using platforms that allow real-time updates and feedback, teams can streamline their workflows, minimize delays, and ensure everyone is aligned on project goals. This approach not only enhances collaboration but also helps in quickly resolving any challenges that may arise during the printing process.

Lastly, consider adopting cloud-based solutions that enable remote monitoring of your printing projects. This allows for real-time adjustments and troubleshooting, even if you are not physically present at the printer. By staying connected with your projects and being able to intervene at any moment, you can maximize efficiency and ensure that your Carbon 3D printer operates at its full potential.

5 Digital Tips for Maximizing Efficiency with Your Carbon 3D Printer

This bar chart illustrates the impact of various digital tools on the efficiency of carbon 3D printing workflows. Each tool contributes differently to overall productivity and time savings.

Regular Maintenance Practices: Ensuring Longevity and Performance of Your Printer

Regular maintenance is crucial for ensuring the longevity and performance of your carbon 3D printer. By adhering to routine upkeep practices, users can avoid common issues that degrade print quality and operational efficiency. For instance, a comprehensive review of machinable ceramic-reinforced composites has highlighted the importance of precision in engineering, underscoring how regular calibration can significantly enhance the consistency of outputs. Studies indicate that printers maintained with regular checks, including nozzle cleaning and software updates, can reduce downtime by approximately 30%, thereby improving overall productivity.

Moreover, integrating emerging sustainable practices into maintenance routines can further optimize performance. As highlighted in recent research, advanced materials used in construction, including those that utilize 3D printing, have led to a re-evaluation of traditional maintenance methodologies. Technologies such as self-healing concrete and advanced cementitious materials not only serve to enhance structural longevity but also align with eco-friendly initiatives. Implementing similar innovative approaches to 3D printer upkeep can minimize waste and incorporate sustainable practices, illustrating a paradigm shift in manufacturing protocols. Regular maintenance, therefore, is not just about immediate performance; it plays a pivotal role in advancing an eco-conscious production environment.

Comparative Analysis: Evaluating Different Carbon Printer Models for Optimal Efficiency

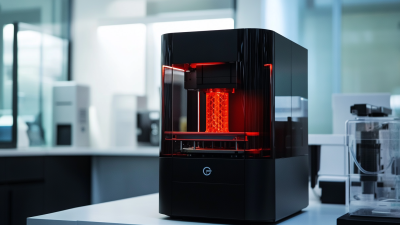

When considering the efficiency of Carbon 3D printers, it's essential to evaluate the various models available on the market. Different printers offer unique features that cater to specific printing needs, leading to significant differences in efficiency and output quality. For instance, the Carbon M2 and the latest L1 models can print at different speeds and resolutions, which may directly influence your production workflow. Conducting a comparative analysis of these models can help identify the best fit for your projects, ensuring you maximize your resources.

In addition to speed and resolution, it’s crucial to assess the technology underpinning each printer. Carbon’s use of Digital Light Synthesis (DLS) sets a standard for precision and material versatility, but some models may come equipped with enhanced capabilities like larger build volumes or specialized resin tanks. By focusing on attributes such as layer adhesion, post-processing requirements, and overall material efficiency, individuals can make informed decisions that align with their production goals. Understanding these differences allows users to not only streamline their 3D printing processes but also significantly improve their workflow efficiency.

Related Posts

-

Future of 3D Printing in 2025 Essential Trends and Actionable Checklist for Success

-

Innovative Approaches for Global Buyers of 3D Printing Technology

-

The Future of Additive Manufacturing: Unlocking Potential with the Best Carbon Fiber 3D Printers

-

Leading the Charge: Explore the Superiority of China's Best Carbon 3D Printers for Global Buyers

-

Top Choices for Best 3 D Printing Solutions Across Global Markets

-

Ultimate Guide to Choosing the Best Carbon Fiber 3D Printer for Your Business Needs