Addressing Common Issues Associated with Nylon Filament in Modern Manufacturing

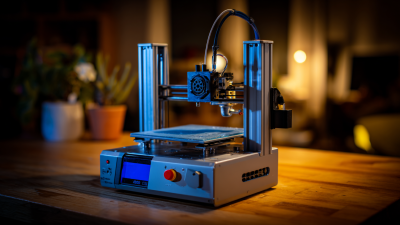

In the realm of modern manufacturing, Nylon Filament has emerged as a pivotal material due to its remarkable properties, including high strength, flexibility, and resistance to wear and chemicals. According to a report by Smithers Pira, the global market for nylon filament in 3D printing alone is expected to reach $1.5 billion by 2025, reflecting a compound annual growth rate (CAGR) of 18.2%. However, the increasing reliance on nylon filament also brings forth a range of common issues that can impede production efficiency and quality. These challenges often include warping, moisture absorption, and layer adhesion problems, necessitating a comprehensive understanding of the material and its behavior in diverse manufacturing environments. This tutorial aims to address these prevalent issues, offering practical solutions to optimize the use of Nylon Filament in production processes and enhance overall product quality.

Understanding the Properties of Nylon Filament for Manufacturing Applications

Nylon filament has emerged as a pivotal material in modern manufacturing, owing to its unique combination of strength, flexibility, and resistance to wear. According to a report by MarketsandMarkets, the global nylon market is projected to reach USD 32.5 billion by 2027, driven largely by its applications in automotive, textiles, and consumer goods. Nylon’s excellent tensile strength, which can range from 70 to 200 MPa, makes it suitable for producing durable parts that can withstand heavy loads without deforming. This resilience under stress is one of the reasons why nylon is favored for components like gears and bearings.

Moreover, nylon's thermal stability and chemical resistance contribute to its versatility in various manufacturing settings. With a melting temperature typically around 220°C, it can be processed using advanced techniques like injection molding and 3D printing. These properties enable manufacturers to produce intricate designs that require a material capable of maintaining structural integrity across a range of environmental conditions. The ability of nylon to absorb moisture—approximately 2.5% in equilibrium with 50% relative humidity—also poses challenges that engineers must address to ensure performance consistency. As industries continue to evolve, understanding these properties will be essential for optimizing the use of nylon filament in manufacturing applications.

Common Challenges Faced When Using Nylon Filament in Production

Nylon filament has gained popularity in modern manufacturing due to its strength and versatility; however, users often encounter several challenges during production. One common issue is warping, which occurs as the nylon cools, causing the printed part to deform. This can be mitigated by ensuring a consistent temperature in the build chamber and utilizing a heated bed, which helps in adhering the print to the surface while minimizing stress in the material.

Another frequent problem is poor layer adhesion. Nylon filament requires specific printing conditions, such as optimal nozzle temperature and print speed, to ensure that each layer bonds effectively. Inadequate adhesion can lead to weak spots and ultimately affect the structural integrity of the final product. Additionally, moisture absorption presents a significant challenge, as nylon is hygroscopic and can absorb water from the air, leading to degradation of the filament quality. Proper storage solutions are essential to maintaining filament longevity, which, in turn, ensures high-quality parts are produced in 3D printing projects.

Effective Strategies for Minimizing Warping and Shrinkage in Nylon Parts

When manufacturing nylon parts, warping and shrinkage are significant challenges that can compromise product quality and performance. These issues often stem from the material's inherent properties, such as its high thermal expansion coefficient and moisture absorption characteristics. According to a recent report by the American Society for Testing and Materials (ASTM), improper temperature control during the printing process can lead to dimensional inaccuracies of up to 1.5%, which further exacerbates these complications.

To minimize warping, it is essential to maintain a stable print temperature. A heated print bed can significantly improve adhesion and reduce the risk of warping. Set the bed temperature between 70-90°C, as this has been shown to decrease differential cooling rates across the printed part, according to research from the Society of Manufacturing Engineers (SME). Additionally, using an enclosure during the printing process can help maintain an even temperature, which is crucial for nylon filaments.

For addressing shrinkage, consider optimizing the cooling settings. Slower cooling rates allow the nylon to retain more heat, thereby preventing rapid contraction. Also, utilizing moisture control strategies, such as storing nylon filaments in a dry environment, can mitigate the material's tendency to absorb moisture, which can otherwise lead to undesirable changes in dimension. Employing these strategies can lead to more reliable and higher-quality nylon parts in your manufacturing processes.

Techniques for Overcoming Moisture Absorption Issues in Nylon Filament

Moisture absorption is a well-known challenge when working with nylon filaments, particularly in modern manufacturing processes. According to a study by the American Society for Testing and Materials (ASTM), nylon can absorb up to 8% of its weight in moisture, which significantly affects its mechanical properties. This high hygroscopicity can lead to issues such as dimensional instability and reduced strength, impacting the overall quality of the final products. Therefore, manufacturers must adopt effective techniques to mitigate these concerns.

One effective approach is implementing pre-drying methods before filament use. A report from J. Mater. Sci. indicates that heating nylon at 80°C for several hours can effectively reduce moisture content to acceptable levels, enhancing dimensional stability during processing. Another technique involves using moisture-resistant packaging as recommended by the Polyamide Polymer Association, which emphasizes the use of desiccants and vacuum-sealed containers for storage. These practices not only help in maintaining the integrity of nylon filaments but also improve the consistency and reliability of products in production, ultimately leading to better performance in various applications.

Best Practices for Optimizing 3D Printing Settings with Nylon Material

When working with nylon filament in 3D printing, optimizing your settings can make a significant difference in the final output. First and foremost, consider the temperature settings for both the nozzle and the print bed. Nylon typically requires higher extrusion temperatures, usually between 240°C and 260°C, to ensure proper melting and flow. Additionally, maintaining a heated bed temperature between 70°C and 90°C can help prevent warping, a common issue associated with nylon due to its high thermal contraction.

Another crucial aspect to consider is the printing speed and layer height. Slower printing speeds, generally around 30-50 mm/s, allow for better layer adhesion and detail retention in nylon prints. Furthermore, a layer height of 0.1 to 0.2 mm is recommended for achieving smoother finishes on intricate designs. Incorporating a brim or raft can also enhance bed adhesion and reduce the likelihood of warping, particularly for larger prints. By fine-tuning these parameters, manufacturers can maximize the benefits of nylon’s strength and flexibility while minimizing common printing challenges.

Related Posts

-

Top Strategies for Sourcing High-Quality Nylon Filament: Metrics and Insights for Global Buyers

-

Unlocking the Benefits of Best Nylon Filament: After-Sales Support and Future Maintenance Savings

-

Digital Guide to Crafting the Best 3D Printed Parts Efficiently

-

10 Essential Features of the Best Large 3D Printers for Global Buyers

-

Comprehensive Insights on 3D Printing Materials for Global Buyers

-

Exploring the Unique Features and Uses of the Best Small 3D Printer and How to Choose the Right One