Revolutionizing Prototyping with Large 3D Printers Unleashing Creativity and Innovation

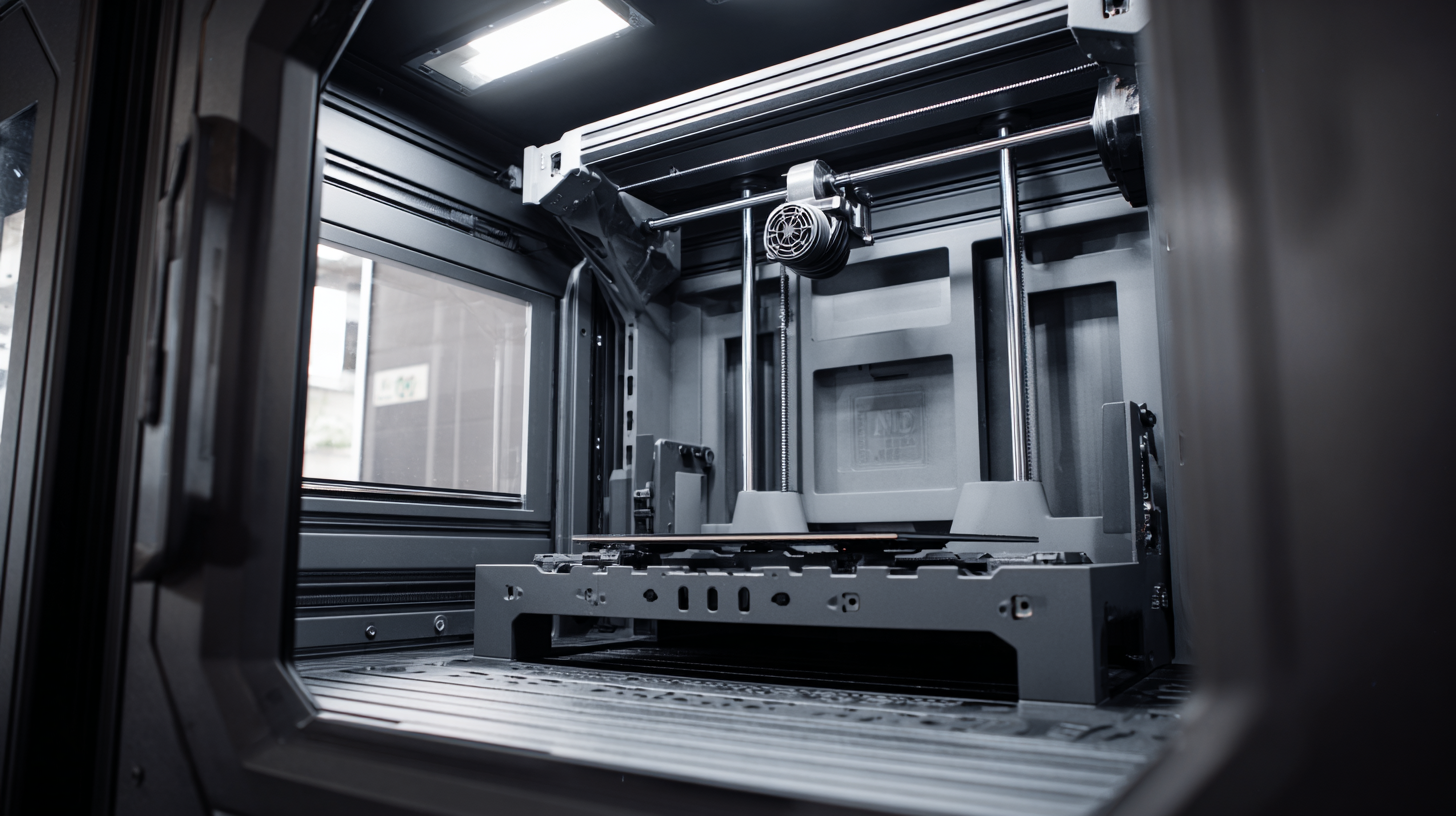

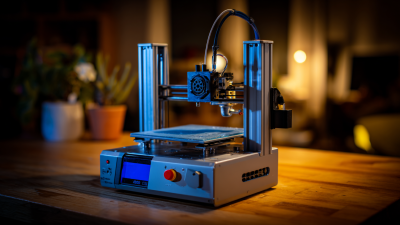

In the evolving landscape of design and manufacturing, the emergence of large 3D printers is revolutionizing the prototyping process, offering unprecedented levels of creativity and innovation. This cutting-edge technology allows designers and engineers to transform their ideas from mere concepts into tangible forms at an impressive scale. With the ability to produce larger prototypes in a fraction of the time traditionally required, large 3D printers not only streamline workflow but also facilitate more complex and intricate designs that were once deemed impractical.

The newfound freedom of creativity enabled by these machines is breaking down barriers and fostering a culture of experimentation across various industries. As we delve into this topic, we will explore how large 3D printers are redefining the prototyping landscape, empowering creators to push boundaries and explore new horizons in product development and design.

Exploring the Capabilities of Large 3D Printers in Prototyping

The capabilities of large 3D printers are redefining prototyping across various industries, driving innovation and allowing for unprecedented creativity. Recent developments showcased at Milan Design Week 2025 highlighted how additive manufacturing is being embraced not just for rapid prototyping but also for producing complex, large-scale designs. These advancements allow designers and engineers to iterate rapidly and visualize concepts that were previously constrained by traditional manufacturing limitations.

For instance, the automotive sector is increasingly exploring the potential of large-scale 3D printing for creating personalized car components, with one-piece parts like spoilers demonstrating a shift towards more efficient, lightweight solutions. This trend reflects a broader movement in manufacturing, where 3D printing is no longer seen just as a prototyping tool, but as a vital part of the production process, enabling bespoke solutions tailored to specific customer needs. As additive manufacturing evolves, its role in facilitating innovation continues to expand, paving the way for future advancements in design and production methodology.

Revolutionizing Prototyping with Large 3D Printers Unleashing Creativity and Innovation

| Prototyping Dimension | Capability | Material Options | Applications | Advantages |

|---|---|---|---|---|

| Build Volume | Up to 1m³ | PLA, ABS, PETG, Nylon | Automotive parts, Prototypes, Fixtures | Reduced lead times, Larger prototypes |

| Layer Resolution | 100 to 300 microns | PLA, TPU, PETG | Consumer products, Art, Custom tools | Fine detail, High flexibility |

| Speed | Up to 400 mm/s | PLA, ABS, Composites | Rapid prototyping, Short runs | Increased productivity, Cost efficiency |

| Precision | ±0.1 mm | High-strength polymers | Engineering models, Architectural designs | High accuracy, Reliable prototypes |

Transforming Design Processes: Speed and Efficiency through 3D Printing

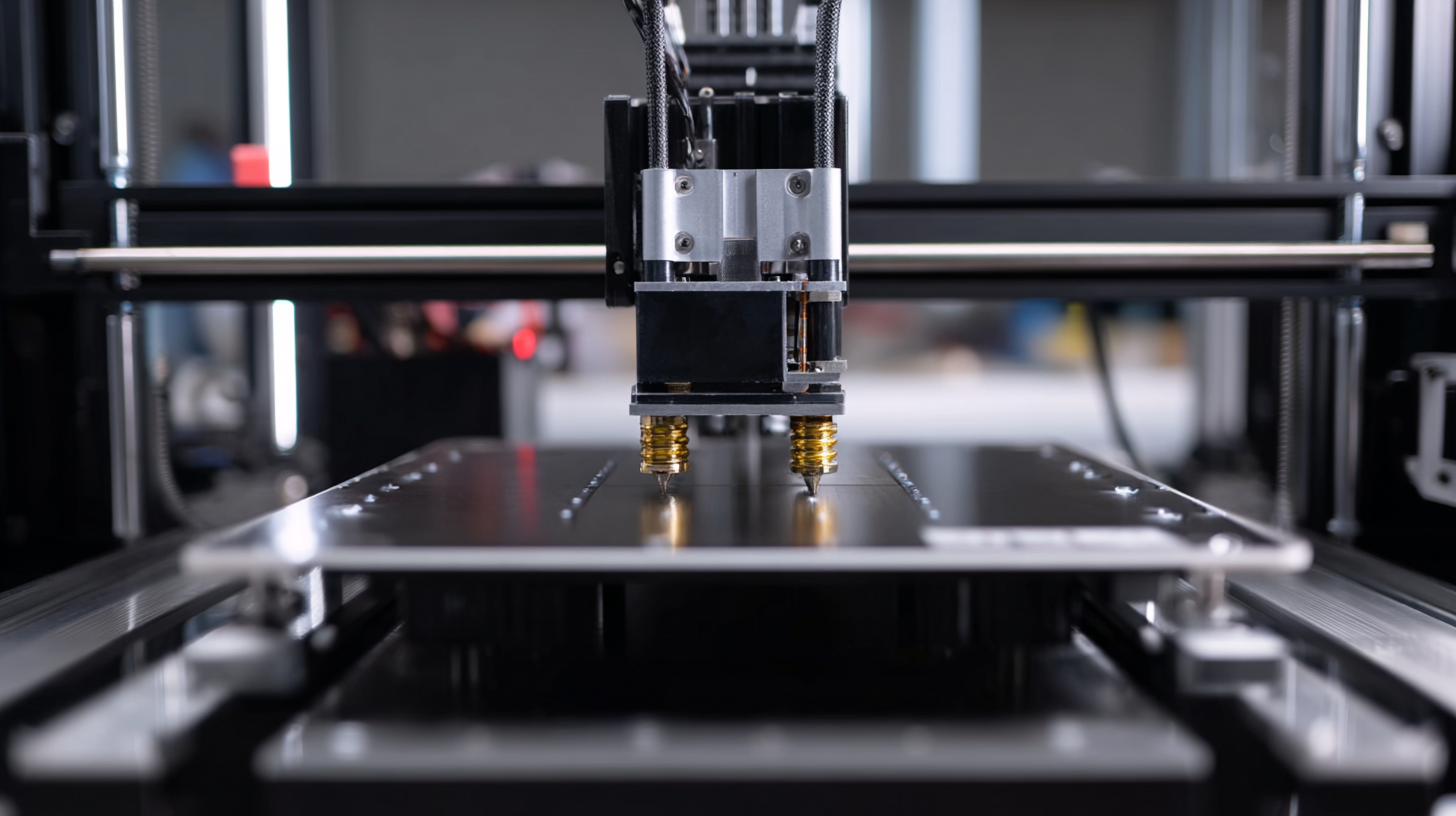

The integration of large 3D printers into design processes is transforming industries by significantly enhancing speed and efficiency. This innovation allows companies to create prototypes quickly, reducing the time from concept to market. For instance, in the fast-paced world of automotive racing, 3D-printed components are being utilized to meet the rigorous demands of performance and precision. This technology enables designers to iterate rapidly, making adjustments in real-time and pushing the boundaries of creativity.

Moreover, advancements such as multi-material printing are enabling engineers to develop complex structures with improved functionality. These methods promote better bonding between different materials, essential for applications across various sectors including aerospace and medical fields. As the prototyping landscape evolves, industries are capitalizing on the speed offered by 3D printing, leading to innovative solutions that meet consumer demands more efficiently than ever before. In this era of rapid development, the ability to convert digital designs into tangible products instantly is revolutionizing how businesses operate and compete.

Fostering Innovation: How Large Printers Enable Creative Expression

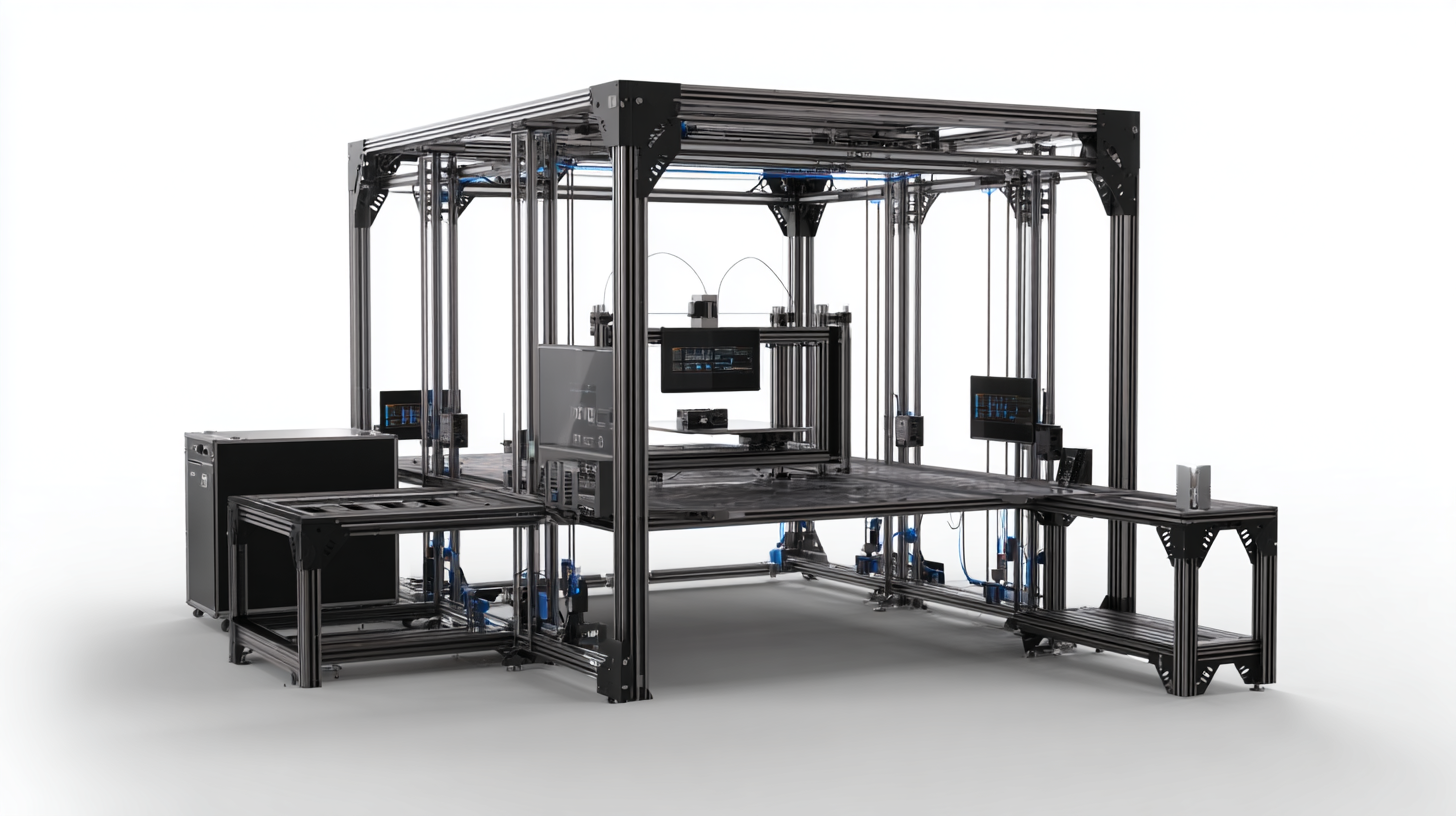

The advent of large 3D printers has fundamentally transformed the landscape of creative expression across various industries. According to a recent report by Wohlers Associates, the global 3D printing market is expected to grow from $12.6 billion in 2021 to over $34.8 billion by 2026, highlighting the significant increase in adoption of these technologies. Large format 3D printers not only allow designers and engineers to prototype at unprecedented scales but also enable an unparalleled level of detail and complexity in their creations. This capability is fostering innovation by empowering creators to push the boundaries of conventional design.

Moreover, industries such as automotive and architecture are embracing large 3D printing to rapidly iterate and refine their concepts. For instance, a study by SmarTech Analysis indicates that large-scale 3D printing could reduce the time needed for prototyping by up to 80%, enabling companies to bring products to market faster while still maintaining high quality standards. This acceleration in the prototyping process encourages a culture of experimentation, allowing designers to take risks and express their creativity in ways that were previously limited by traditional manufacturing constraints. With these advancements, large 3D printers are not merely tools; they are catalysts for innovation and creativity across diverse fields.

Large 3D Printers and Innovation in Prototyping

This chart illustrates the correlation between the size of 3D printers and the number of innovative prototypes developed in various industries over the past year.

Case Studies: Successful Applications of Large-Scale 3D Prototyping

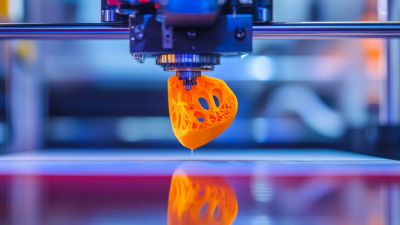

Large-scale 3D printing has transformed the prototyping landscape across various industries, enabling companies to turn innovative ideas into tangible products swiftly.

One notable case study is that of a prominent automotive manufacturer that utilized a large 3D printer to produce a full-scale prototype of a new vehicle design.

This rapid prototyping method not only reduced the time from concept to execution but also allowed for immediate modifications based on real-world testing.

The ability to create intricate parts in a single print cycle minimized assembly time and improved the overall design quality, showcasing how large 3D printers can streamline manufacturing processes.

Another compelling example comes from the architecture sector, where a leading firm employed large-scale 3D printing to construct a detailed model of a new urban development project.

The firm could showcase various design options to stakeholders in a fraction of the time traditional methods would have required.

The precision and scale of the model facilitated better communication and feedback, significantly enhancing the design iteration process.

These case studies illustrate the profound impact large 3D printers have on fostering creativity and driving innovation, proving essential for industries striving to stay ahead in a competitive market.

Future Trends: The Evolution of 3D Printing in Product Development

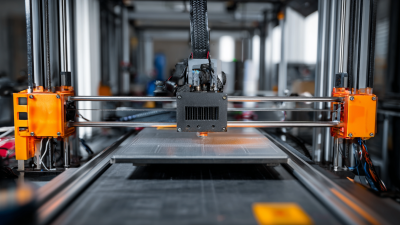

The evolution of 3D printing technology has significantly influenced product development, leading to a transformative impact on how prototypes are created. As materials and printing techniques continue to advance, designers can now explore complex geometries and innovative structures that were previously unimaginable. This newfound flexibility allows for faster iterations, enabling teams to bring ideas to life quickly and efficiently, thus accelerating the overall development cycle.

Looking ahead, the trend of large-scale 3D printing is poised to revolutionize not just prototyping, but also manufacturing on a broader scale. Innovations such as multi-material printing and enhanced software integration are setting the stage for more sophisticated designs and customization options. As industries embrace these advancements, the boundaries between digital and physical realms will blur, fostering a culture of creativity that empowers entrepreneurs and established companies alike to push the limits of what's possible in product design.

Related Posts

-

10 Essential Features of the Best Large 3D Printers for Global Buyers

-

How to Choose the Right Professional 3D Printer for Your Business Needs

-

Exploring the Best Options for Top 3d Printers That Suit Your Business Needs

-

Exploring the Unique Features and Uses of the Best Small 3D Printer and How to Choose the Right One

-

5 Compelling Reasons Commercial 3D Printers Transform Business Efficiency and Innovation

-

How to Maximize Efficiency with a Large 3D Printer in Your Business