Unlocking the Secrets to Sourcing High-Quality 3D Printer Filament for Your Business

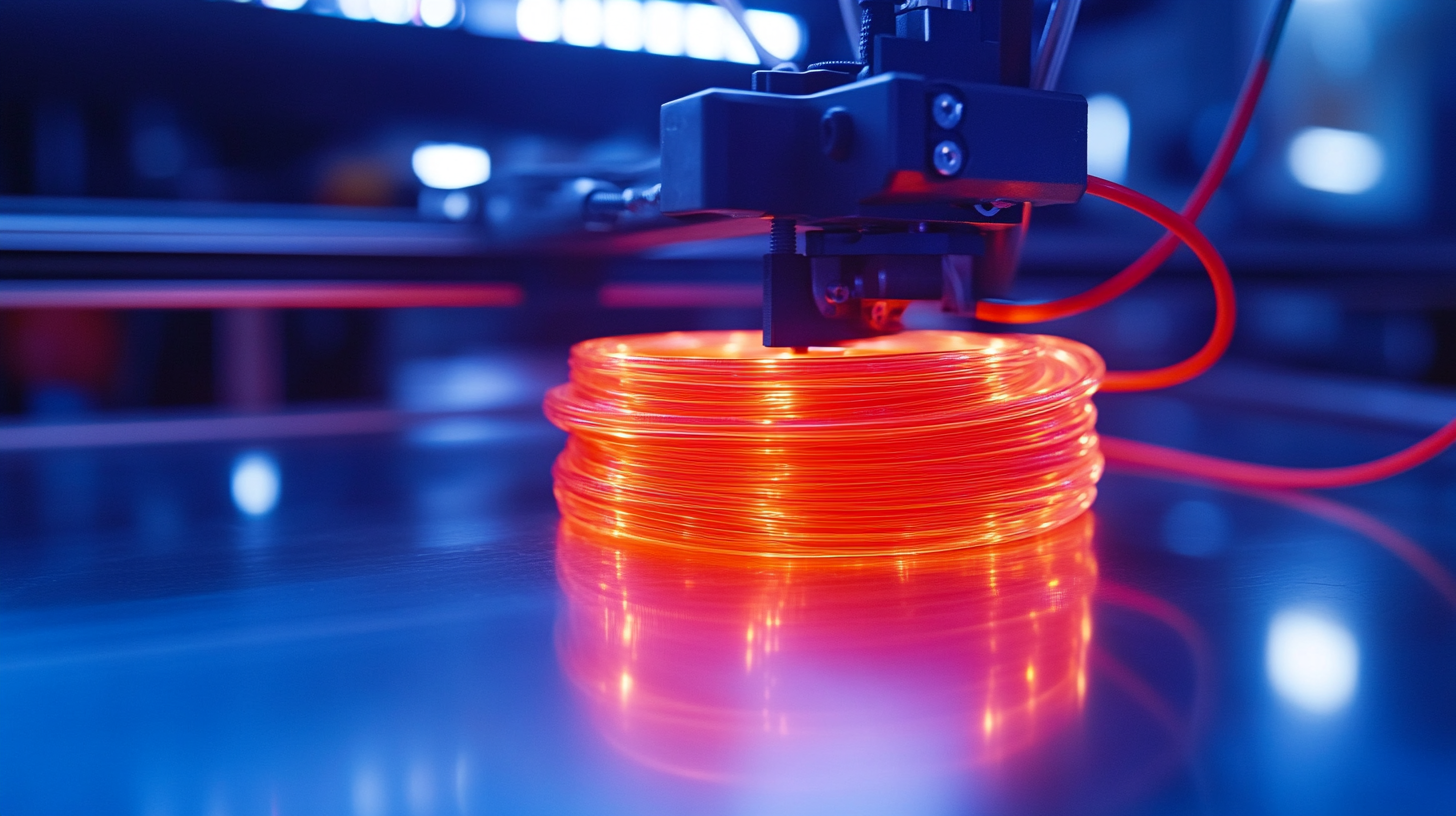

In the rapidly evolving world of 3D printing, the quality of your final products often hinges on the type of materials you use. Among these materials, 3D printer filament stands out as a critical component that can make or break your printing projects. Whether you're a small business looking to produce prototypes or an established manufacturer aiming to innovate, understanding how to source high-quality 3D printer filament is essential. With a plethora of options available on the market, making informed decisions about filament selection can significantly impact your business’s efficiency, output quality, and overall success.

However, sourcing the right 3D printer filament involves more than just choosing a popular brand or color. Factors such as filament composition, diameter consistency, and supplier reliability play a crucial role in ensuring your printing process runs smoothly. In this blog, we will unlock the secrets to effectively sourcing high-quality 3D printer filament. We will explore key considerations, provide tips for evaluating suppliers, and offer insights into the types of filaments that best suit various printing applications, empowering you to make smarter choices for your business.

Understanding the Importance of High-Quality 3D Printer Filament for Business Success

Understanding the quality of 3D printer filament is essential for businesses aiming to excel in today's competitive marketplace. High-quality filament not only enhances the performance of 3D printers but also directly influences the outcome of printed products, from their durability to aesthetic appeal. When businesses invest in superior filament, they set the foundation for producing reliable prototypes and final products that meet customer expectations and industry standards. Moreover, the importance of sourcing high-quality filament goes beyond just the end product. It impacts the entire production process, including printing speed and maintenance requirements. Filaments made from lower-quality materials can cause clogs and downtimes, leading to increased operational costs and delays in delivering products. Therefore, businesses that prioritize high-quality filament are more likely to streamline their production, reduce waste, and ultimately, boost their bottom line. Lastly, the choice of filament can significantly affect a company's reputation. In an age where customer satisfaction hinges on quality, using subpar materials can tarnish a brand's image and lead to negative reviews. By committing to the use of high-quality 3D printer filament, businesses not only improve their product quality but also foster customer trust, securing a competitive advantage in the evolving market landscape.

Key Factors to Consider When Sourcing 3D Printer Filament

When sourcing high-quality 3D printer filament for your business, there are several key factors to consider to ensure you select the right materials for your specific needs. First and foremost, understanding the material properties is crucial. Different filaments, such as PLA, ABS, and PETG, have unique characteristics that impact their performance in various applications. For instance, while PLA is known for its ease of use and excellent print quality, ABS offers greater strength and heat resistance, making it suitable for functional prototypes. Assessing the nature of your projects will help you determine which filament material aligns best with your requirements.

Another significant factor is the consistency and reliability of the supplier. Not all filament manufacturers offer the same level of quality control and consistency, which can affect your production outcomes. Look for suppliers who provide detailed specifications and have a reputation for delivering filament with minimal diameter variation and impurities. Reading reviews and testimonials related to the filament's performance can also offer insights into the supplier's reliability, helping you avoid potential printing issues down the line.

Finally, consider the cost-effectiveness of your choices. While it might be tempting to select the cheapest options available, investing in higher-quality filaments typically yields better printing results and reduces waste. Evaluate bulk purchasing options or long-term partnerships with suppliers who can offer competitive pricing without compromising on quality. Balancing quality, reliability, and cost will empower your business to thrive in the growing 3D printing market.

Evaluating Filament Suppliers: What to Look For

When evaluating filament suppliers for high-quality 3D printer filament, there are several key factors to consider. First and foremost, the consistency of filament quality is crucial. Look for suppliers who provide comprehensive specifications, including diameter accuracy and tolerance levels, as inconsistencies can lead to print failures and wasted materials. Reviews and testimonials from other businesses can offer valuable insights into a supplier's reliability and product performance.

Another important aspect to examine is the range of filament options available. Suppliers who offer diverse types of materials, such as PLA, ABS, and PETG, can be more beneficial for businesses looking to experiment with different printing applications. It's also essential to consider the source of the materials; many high-quality filaments are made from comprehensive, well-documented processes, ensuring that they meet industry standards.

In addition, engagement and support from suppliers can significantly impact your experience. A supplier that provides technical assistance, recommendations for optimizing print settings, and addresses concerns promptly demonstrates a commitment to customer satisfaction. Ultimately, assessing these factors can help you unlock the secrets to sourcing high-quality filament that meets your business needs and enhances your 3D printing capabilities.

The Role of Material Properties in Choosing the Right Filament

When selecting the right 3D printer filament for your business, understanding material properties is crucial. Not all filaments are created equal, and their characteristics can significantly affect print quality, durability, and functionality. According to a report from SmarTech Analysis, the global 3D printing materials market reached $2 billion in 2020, with a notable portion attributed to specialized filaments. This emphasizes the importance of choosing high-quality materials as businesses increasingly rely on 3D printing for production and prototyping.

One of the primary material properties to consider is the filament's viscosity, which can affect how smoothly it flows during extrusion. For example, ABS (Acrylonitrile Butadiene Styrene) is favored for its strength and heat resistance, but it has a higher viscosity than PLA (Polylactic Acid). A study published by the Additive Manufacturing journal highlights that while PLA is easier to print and biodegradable, it may not withstand high temperatures as effectively as ABS. Therefore, businesses must align their filament choice with the intended application, considering factors such as mechanical stress and environmental exposure.

Furthermore, the impact of layer adhesion on finished products cannot be overlooked. Reports from the Society of Manufacturing Engineers indicate that layer adhesion properties are critical for achieving optimal strength in end-use parts. For instance, nylon filaments, known for their excellent mechanical properties, can produce stronger parts when extruded at the right temperature and speed. Thus, a thorough understanding of filament properties and their implications on the final print can lead to better operational efficiency and improved product performance in the competitive landscape of 3D printing.

Tips for Building Long-Term Relationships with Filament Suppliers

Building long-term relationships with filament suppliers is crucial for the sustainability of your 3D printing business. The foundation of any successful partnership lies in open communication. Regularly engaging with your suppliers to discuss your needs, challenges, and expectations fosters trust and transparency. This collaborative environment not only helps in overcoming hurdles but also empowers both parties to innovate. Consider organizing regular meetings or check-ins to keep the lines of communication flowing and to discuss market trends or upcoming projects.

Additionally, demonstrating respect for your supplier’s capabilities can significantly enhance your relationship. Acknowledge their expertise in their material offerings and be open to suggestions they may have. This mutual respect can lead to better quality materials at competitive prices. Moreover, understanding your supplier's operational challenges allows you to collaborate on solutions that benefit both sides, helping to create a resilient supply chain.

Another key factor is inclusive sourcing. By supporting suppliers that prioritize ethical practices and environmentally-friendly processes, you not only enhance your brand's reputation but also contribute to a more sustainable industry. Engage with suppliers who share your values regarding human rights and environmental impacts. This alignment will not only strengthen your partnership but also create a positive ripple effect throughout your network, reinforcing the importance of ethical business practices.