7 Essential Tips for Choosing the Best Large Format 3D Printer for Your Business

In the rapidly evolving landscape of 2025, the significance of adopting advanced technological solutions for businesses cannot be overstated. One exceptional innovation gaining traction is the Large Format 3D Printer, a powerful tool that not only enhances production capabilities but also propels companies toward greater efficiency and creativity. As industries increasingly recognize the transformative benefits that come with leveraging high-quality 3D printing technology, the demand for large format printers is on the rise. These printers enable businesses to produce larger, more complex parts that were previously unattainable with standard-sized models. However, choosing the right Large Format 3D Printer can be a daunting task, with a myriad of options available in the market. In this blog, we will explore seven essential tips to help you navigate the selection process, ensuring that you invest in a printer that aligns perfectly with your business needs and future growth.

Key Considerations for Selecting a Large Format 3D Printer for Business Needs

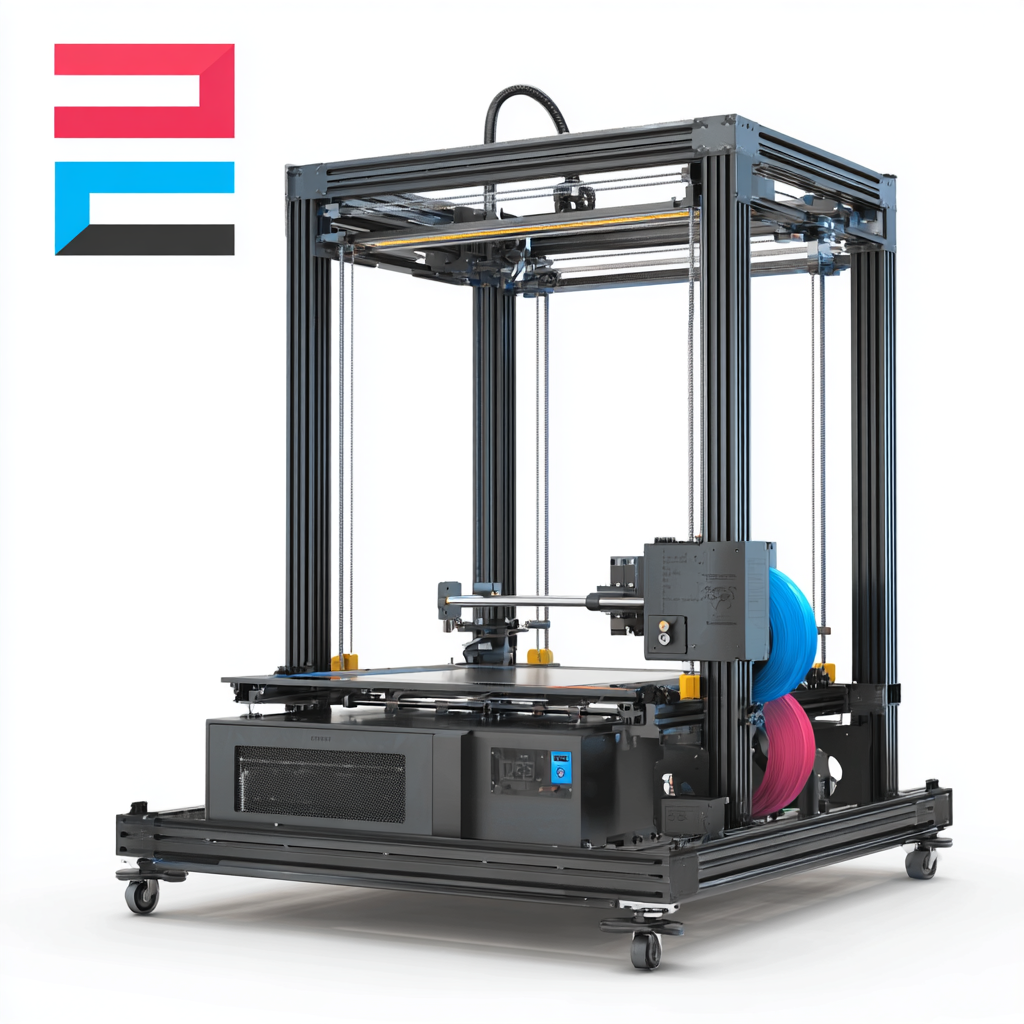

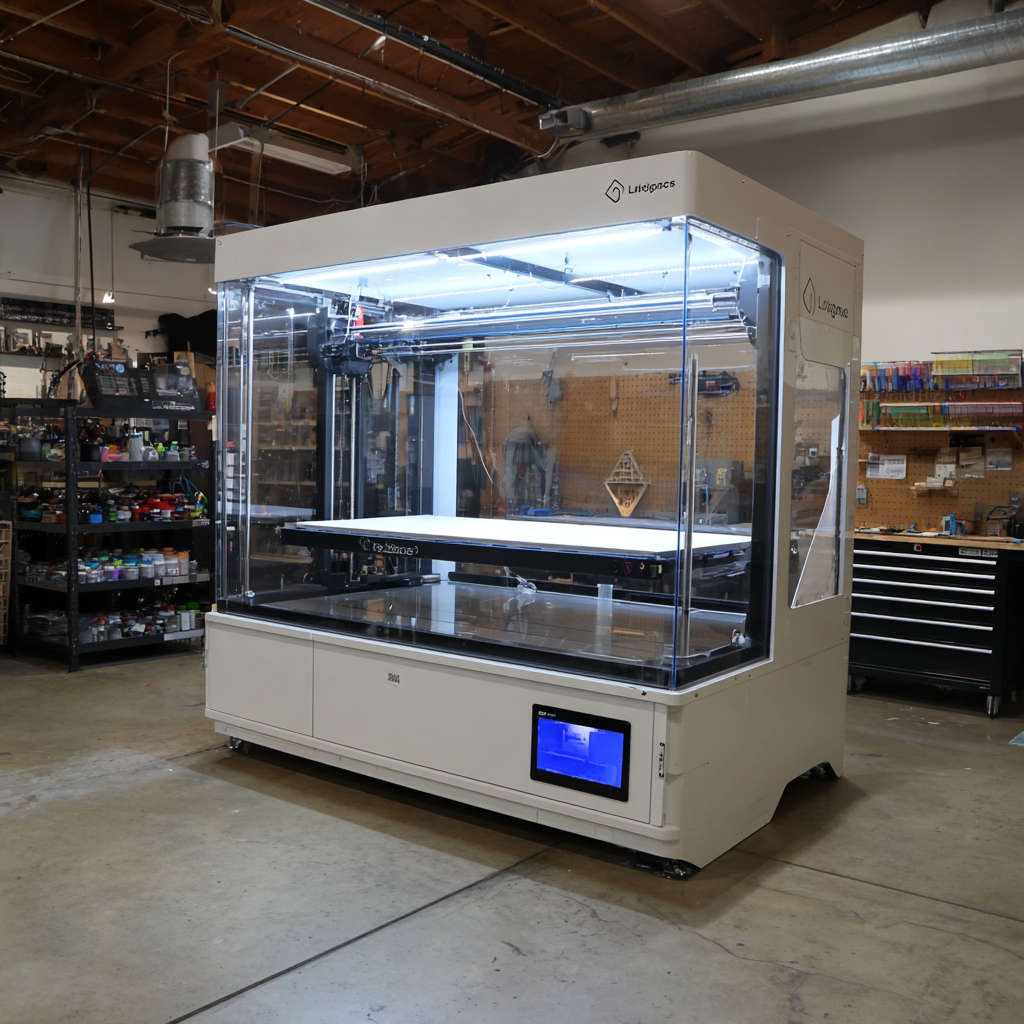

When selecting a large format 3D printer for your business, the most important considerations revolve around your specific needs and production goals. First, evaluate the printer's build volume. A larger build volume allows for the creation of bigger objects, which can be crucial for industries like architecture, automotive, or product prototyping. Ensure that the dimensions fit the scale of your projects without compromising on quality.

Another key factor is material compatibility. Different applications require various materials, and not all large format printers support the same range. Look for a printer that can handle multiple filament types, including high-performance options like ABS, PLA, or specialized composites. This versatility will provide greater flexibility in production, helping your business adapt to diverse client demands and market trends.

Finally, consider the reliability and ease of use of the machine. A user-friendly interface and consistent performance reduce downtime and streamline your workflow. Research customer reviews or request demos to assess the printer's performance in real-time. Prioritizing these considerations will guide you in making an informed decision tailored to your business's specific requirements.

Exploring Industry Applications of Large Format 3D Printing Technology

Large format 3D printing technology has made significant strides across various industries, revolutionizing production processes and offering unprecedented design capabilities. According to a recent report by SmarTech Analysis, the global market for large format 3D printing is projected to exceed $2 billion by 2028, driven by its application in sectors such as aerospace, automotive, and architecture. The ability to create larger parts with minimal assembly is becoming a vital advantage, allowing businesses to streamline operations and enhance product performance.

In the automotive industry, for instance, companies like Ford and BMW leverage large format 3D printers for prototyping and tooling, reducing lead times by up to 90%. Additionally, architecture firms are utilizing this technology to create intricate scale models that help clients visualize projects more effectively. A study from Wohlers Associates indicates that over 55% of architecture firms now use 3D printing as part of their design workflow, underscoring the technology's growing relevance in creating detailed, functional models. As industries continue to adopt large format 3D printing, choosing the right printer will become increasingly crucial for maximizing productivity and innovation.

Different Types of Large Format 3D Printers and Their Unique Benefits

When considering large format 3D printers for your business, it's essential to understand the different types available and their unique benefits. Fused Deposition Modeling (FDM) printers are the most common choice, known for their versatility and cost-effectiveness. They utilize thermoplastic filaments, making them suitable for a variety of industries, from automotive to healthcare. As the market for FDM technology is set to grow substantially in the coming years, investing in this type of printer can yield significant returns.

Another noteworthy option is Stereolithography (SLA), which produces high-resolution models and intricate details, perfect for prototyping and dental applications. The recent introduction of advanced SLA printers showcases rapid production capabilities, making them ideal for businesses that require efficiency without compromising quality. When selecting a large format printer, consider the specific needs of your operations and whether materials like biocompatible polymers can enhance your products, particularly in medical fields where precision is critical.

Evaluating Material Compatibility in Large Format 3D Printing Solutions

When selecting a large format 3D printer for your business,

material compatibility should be at the forefront of your decision-making process. The range of materials available for 3D printing is vast, including thermoplastics, resins, and composites, each with its own unique properties and applications.

Understanding the specifications of the materials you plan to use is crucial, as different printers are optimized for particular types of filaments or resins.

A printer that is versatile in material compatibility can provide your business with the flexibility to experiment with various applications, ultimately enhancing your product offerings.

When selecting a large format 3D printer for your business,

material compatibility should be at the forefront of your decision-making process. The range of materials available for 3D printing is vast, including thermoplastics, resins, and composites, each with its own unique properties and applications.

Understanding the specifications of the materials you plan to use is crucial, as different printers are optimized for particular types of filaments or resins.

A printer that is versatile in material compatibility can provide your business with the flexibility to experiment with various applications, ultimately enhancing your product offerings.

Additionally, consider how material compatibility affects post-processing and final product quality. Some materials may require specific environmental controls or additional finishing techniques after printing. Therefore, it’s important to ensure that the large format 3D printer you choose can accommodate these requirements effectively.

Evaluate the printer’s capabilities to handle different materials and investigate the manufacturer’s recommendations for optimal results.

Taking the time to assess material compatibility thoroughly will not only streamline your production processes but also expand your creative possibilities, enabling your business to stay competitive in the ever-evolving 3D printing landscape.

Understanding Operational Costs and ROI for Large Format 3D Printers

When considering a large format 3D printer for your business, understanding the operational costs and potential return on investment (ROI) is crucial. A thorough analysis of the materials and operational expenses associated with different printers can help you make a more informed decision. Look for printers that offer cost-effective solutions without compromising on quality. Additionally, consider the longevity and maintenance needs of the equipment, as these factors significantly impact overall operational costs over time.

Another essential tip is to evaluate the printer's capabilities in terms of scalability and versatility. A large format printer that can accommodate a variety of materials and adapt to different projects will provide better ROI in the long run. Also, examine the support and training provided by the manufacturer; comprehensive training can minimize operational mistakes and improve production efficiency. By focusing on these aspects, businesses can better position themselves to leverage the benefits of large format 3D printing.