Top 10 Tips for Choosing the Best 3D Printer for Your Needs?

Choosing the right 3D printer can be a daunting task. With so many options available, it's crucial to make an informed decision. Expert Jane Doe, a well-known 3D printing consultant, once said, "Selecting the right 3D printer requires understanding your specific needs." Her insight highlights the importance of personal requirements in this journey.

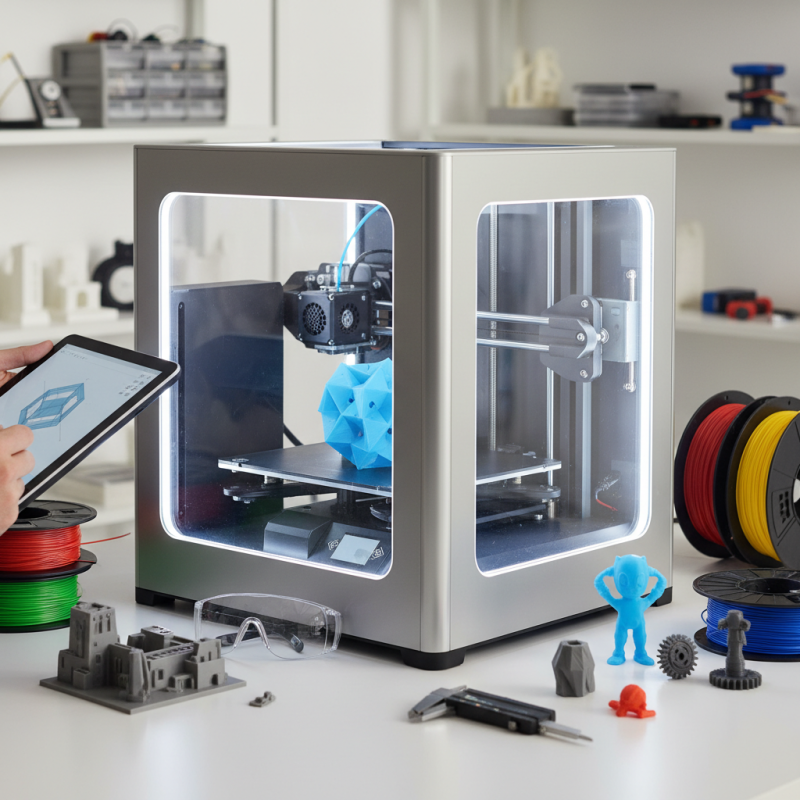

When diving into the world of 3D printing, potential buyers may feel overwhelmed. Each model presents unique features and technology, making the selection process complex. However, knowing the purpose of your 3D printer helps narrow down choices significantly. Consider what you plan to create. Is it for prototyping, hobby projects, or perhaps educational purposes?

Many consumers often overlook crucial aspects during their search. For example, the printing speed and material compatibility are vital factors. If these elements don’t align with your project goals, the experience can be disappointing. Reflection on what truly matters before purchasing will guide you toward better decision-making in the 3D printer market.

Understanding Different Types of 3D Printers: FDM, SLA, and SLS

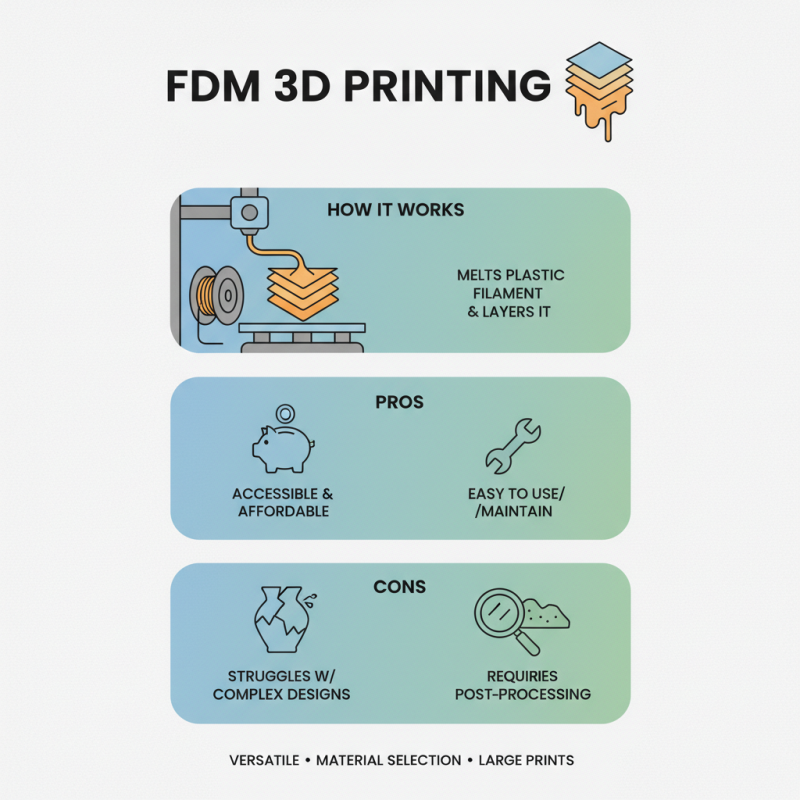

When selecting a 3D printer, understanding the different types available is crucial. Fused Deposition Modeling (FDM) is one of the most common methods. It works by melting plastic filament and layering it to create objects. This technology is accessible and generally affordable. However, FDM printers can struggle with complex designs. The surface finish may not always be smooth or detailed. Many users find themselves adjusting settings repeatedly to get the right output.

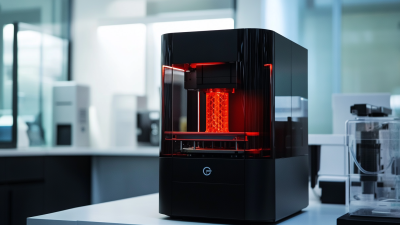

Another option is Stereolithography (SLA). It uses a resin that hardens when exposed to light. SLA can produce high-detail prints. The finished products often have a glossy finish. Nevertheless, the resin can be messy and requires post-processing. Users sometimes find the smell unpleasant. It is also essential to consider the curing process, which can be lengthy.

Selective Laser Sintering (SLS) is more advanced. It uses a laser to fuse powdered material, layer by layer. This method is excellent for creating durable parts. The range of materials is also broader. Yet, SLS printers are generally more expensive and complex. Occasionally, users may face challenges like warping or inconsistent fusing. Each method has its strengths and weaknesses. Choosing the right one involves careful consideration of your specific needs and applications.

Assessing Your Budget: Average Costs of Entry-Level vs. Professional Printers

When selecting a 3D printer, assessing your budget is crucial.

Entry-level printers generally cost between $200 and $500. They are great for beginners.

You can print simple designs. However, these printers may struggle with detail and durability. Think about your needs.

On the other hand, professional printers can range from $1,500 to over $10,000.

They offer high precision and can handle complex projects. If you plan to use the printer for business, investing more might be wise.

These printers often come with advanced features.

Here’s a tip: consider how often you’ll use the printer. If you print occasionally, a lower-cost option might suffice.

Yet, if you frequently create high-quality models, premium printers could save you time and frustration.

Always check the technical specifications. Look for supported materials and print size limits.

Don't forget to factor in maintenance costs, as they can add up.

Evaluating Print Quality: Key Metrics like Layer Resolution and Accuracy

When choosing a 3D printer, evaluating print quality is crucial. Two key metrics are layer resolution and accuracy. Layer resolution determines how fine the details can be. Higher resolution means better detail. However, it often comes with longer print times. Finding a balance is essential.

Accuracy refers to how well a printer reproduces dimensions. It’s important for projects requiring precision. Some printers have slight variances, leading to imperfections in the model. Paying attention to these issues can save time and frustration.

Many beginners overlook these aspects. They might focus on price or aesthetics. Yet, understanding metrics can enhance the overall printing experience. A printer that excels in resolution but lacks in accuracy can lead to disappointing results. Assess your specific needs before deciding.

Material Compatibility: Essential Filaments and Resins for Your Projects

When selecting a 3D printer, material compatibility is key. Different filaments and resins can drastically affect the quality of your project. For instance, PLA is widely popular for beginners. It is easy to use and offers good detail. However, it is not the most durable option. On the other hand, ABS provides better strength, but it can be challenging to work with due to warping issues.

Consider your project's demands. If you are creating prototypes, PLA may suffice. Yet, for functional parts, explore options like PETG or nylon. Both materials offer enhanced toughness. Resins, on the other hand, add another layer of complexity. They can deliver stunning detail for miniatures or intricate designs but often require post-processing. The cleanup can be time-consuming. Not all printers handle all materials well; be mindful of your machine's capabilities.

In the journey of choosing, you might find yourself overwhelmed. Different projects may need different materials. Experimentation is invaluable. Sometimes, what works perfectly for one project flops for another. Embrace the learning process, and don’t shy away from making mistakes. Each failed print is an opportunity for growth.

Material Compatibility: Essential Filaments and Resins for Your 3D Printing Projects

Researching Brand Reliability and Customer Support in the 3D Printing Industry

When selecting a 3D printer, brand reliability matters significantly. Some brands have established a strong reputation for durability and innovation. Their long-standing presence often suggests stability. Look for reviews that highlight user experiences with specific brands. Positive feedback frequently reflects excellent customer support.

Good support can reduce frustration. Technical issues can arise unexpectedly. A company that responds quickly is essential. Delays in responses can lead to lost projects. Some brands may promise a lot but fail in service. Researching forums can provide genuine insights into customer satisfaction.

Consider how easily you can access replacement parts. Some brands offer a wider range than others. This availability can prolong the printer’s life. Also, check for online resources or community support. Active user groups can provide practical tips. These interactions often enhance your experience and knowledge. A brand with a strong community backing can make a difference in your journey.

Related Posts

-

Future of 3D Printing in 2025 Essential Trends and Actionable Checklist for Success

-

Top Choices for Best 3 D Printing Solutions Across Global Markets

-

5 Digital Tips for Maximizing Efficiency with Your Carbon 3D Printer

-

Innovative Approaches for Global Buyers of 3D Printing Technology

-

Leading the Charge: Explore the Superiority of China's Best Carbon 3D Printers for Global Buyers

-

The Future of Additive Manufacturing: Unlocking Potential with the Best Carbon Fiber 3D Printers