10 Essential Features of the Best Large 3D Printers for Global Buyers

In recent years, the demand for Large 3D Printers has surged, driven by industries ranging from aerospace to healthcare. These advanced machines are capable of producing intricate designs and large-scale prototypes that were once deemed impossible to achieve. As businesses and hobbyists alike recognize the benefits of scalable manufacturing and rapid prototyping, understanding the essential features of the best large 3D printers becomes crucial for making informed purchasing decisions.

This blog will explore the ten key features that define high-quality large 3D printers, ensuring that buyers can navigate the diverse offerings in the market. From build volume and printing materials to ease of use and software compatibility, these elements will help you identify the right machine to suit your unique needs. Whether you are an industry professional or an enthusiast looking to expand your creations, knowing what to look for will empower you to choose a large 3D printer that delivers both performance and value.

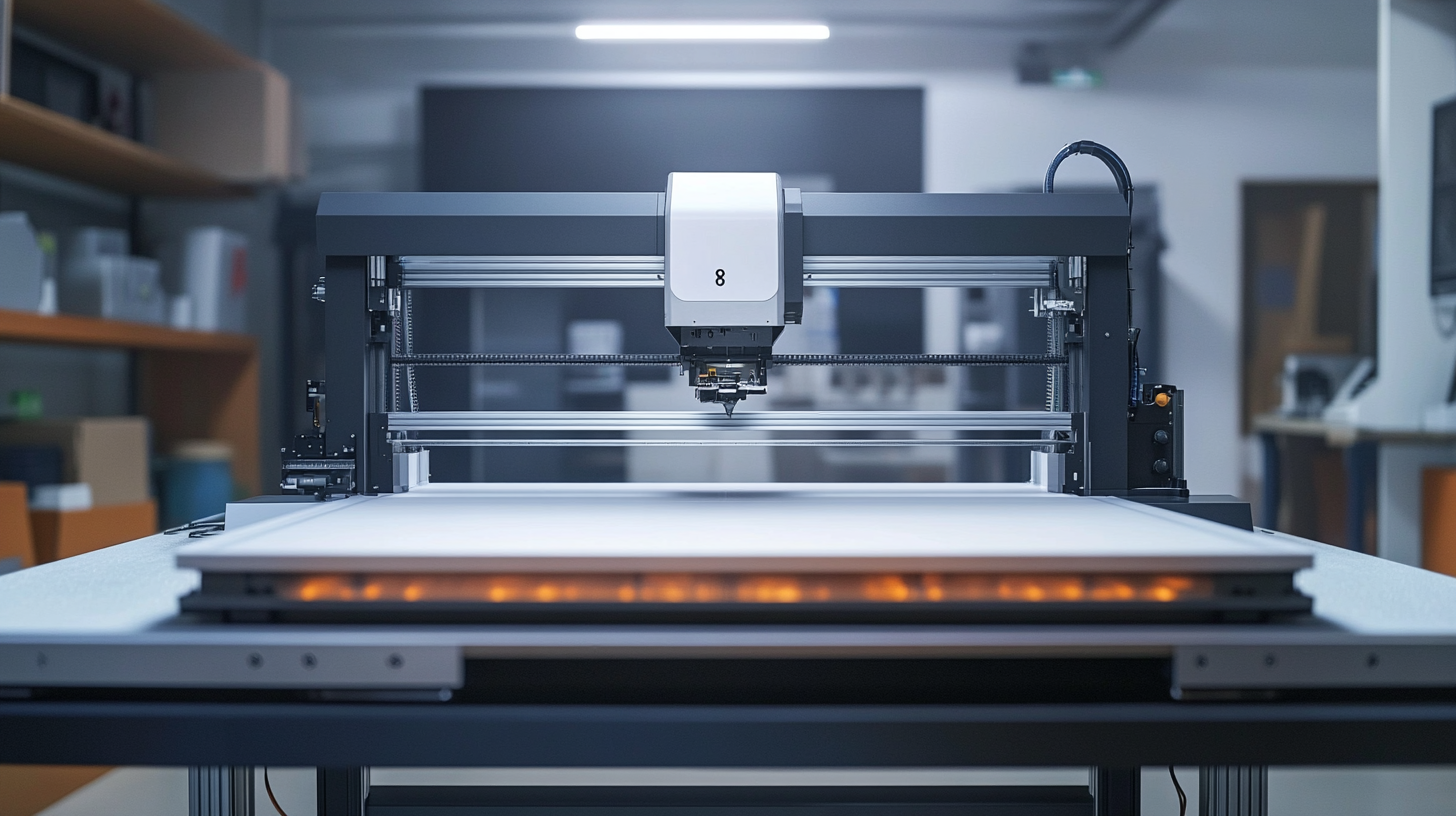

Key Considerations for Sizing and Capacity in Large 3D Printers

When selecting a large 3D printer, sizing and capacity are critical factors that significantly influence operational efficiency and project outcomes. Large 3D printers are designed to accommodate big builds, which means that understanding the dimensions of the print bed is essential. A more spacious build platform allows users to create larger prototypes or multiple parts in one go, effectively reducing production time and minimizing material waste. Buyers should carefully evaluate their specific needs, considering the types of projects they plan to undertake and how frequently they need to produce large-scale objects. In addition to print bed size, the overall build volume is an essential consideration. Different applications may require varying heights, widths, and depths; thus, prospective buyers should assess the maximum capacity based on their intended use. It's also important to consider how the printer's capacity aligns with the materials intended for use. Some materials may have specific requirements that could affect the design and implementation of larger prints. Therefore, a well-rounded approach involves anticipating future projects while ensuring that the chosen large 3D printer can adapt to evolving demands in production and design.

Material Compatibility: Essential Varieties for Versatile Printing

When considering large 3D printers, material compatibility plays a pivotal role in determining their versatility and overall value for global buyers. The ability to work with a variety of materials ensures that users can print a wide range of applications, from prototypes to functional parts. According to a report by MarketsandMarkets, the global 3D printing materials market is projected to reach USD 2.78 billion by 2023, indicating a growing demand for printers that can handle diverse materials.

One of the key features to look for in large 3D printers is their ability to work with different filament types, including ABS, PLA, PETG, and various engineering plastics. For instance, advanced printers capable of using nylon or carbon fiber composites can cater to industries such as aerospace and automotive, where the mechanical properties of the printed parts are crucial. A study from Wohlers Associates highlights that over 50% of the high-end 3D printing market is driven by functional prototyping, reinforcing the need for printers that can leverage a broad spectrum of materials.

Furthermore, the adaptability of large 3D printers to work with multiple materials enhances efficiency and reduces waste. This not only allows manufacturers to produce complex geometries but also significantly lowers material costs. Businesses that invest in multi-material capabilities can optimize their production cycles, as they can switch materials seamlessly without additional setup time. This feature becomes especially important in fast-paced manufacturing environments, where time and resource efficiency are critical.

Precision and Accuracy: How to Measure Performance Standards

When it comes to assessing the best large 3D printers on the market, precision and accuracy are paramount. Accurate printing is measured through several performance standards, including dimensional accuracy, repeatability, and layer resolution. According to a study by Wohlers Associates, the average dimensional accuracy of industrial-grade 3D printers is between ±0.1 to ±0.5 mm, an essential factor for industries requiring tight tolerances like aerospace and automotive manufacturing.

To measure the performance standards effectively, buyers should consider metrics such as the printer's layer height and nozzle diameter. The layer height typically influences the smoothness of the final print, with standard resolutions ranging from 50 to 300 microns. Notably, manufacturers like Stratasys and Ultimaker boast models that can achieve incredible resolutions of up to 20 microns, positioning them favorably in a competitive market. In addition, repeatability, which indicates how consistently a printer can produce identical prints, is often tested through benchmark objects, showing variances of less than 0.2 mm in quality models.

Moreover, the build volume and print speed are also crucial aspects, as they impact the printer's overall productivity. A report from Smartech Publishing highlights that the demand for large format 3D printers has been steadily rising, with a projected growth rate of over 25% per year through 2025. As buyers evaluate their options, understanding the precision and accuracy measurements will be key to making informed decisions in the ever-evolving landscape of 3D printing technology.

User-Friendly Interfaces: Importance of Software for Global Users

When it comes to large 3D printers, a user-friendly interface is an essential feature that can significantly impact the overall experience for global users. The interface serves as the bridge between the user and the sophisticated technology of 3D printing, and having an intuitive software system can make or break the printing process. For users who may not have extensive technical expertise, an easy-to-navigate interface can simplify complex tasks, allowing them to focus on creativity and innovation rather than getting bogged down by the intricacies of the technology.

The importance of software cannot be overstated, especially for international buyers who may face language barriers. Multi-language support is a vital aspect of user-friendly interfaces, enabling users from diverse backgrounds to operate the printer seamlessly. Moreover, features like graphical wizards and guided workflows can provide step-by-step assistance, empowering users to effectively utilize the 3D printer without prior in-depth knowledge. By removing these hurdles, manufacturers can enhance user experience, leading to higher satisfaction and productivity.

In addition to usability, the integration of advanced software features such as remote monitoring and real-time analytics greatly benefits users. These capabilities allow operators to track printing progress, troubleshoot issues on the fly, and optimize print settings from anywhere in the world. As the global market for large 3D printers continues to grow, prioritizing user-friendly software will be critical for manufacturers looking to attract and retain customers.

Maintenance and Support: Ensuring Longevity in Large 3D Printing Systems

Maintaining large 3D printing systems is crucial for ensuring their longevity and optimal performance. Regular maintenance not only minimizes the risk of unexpected breakdowns but also enhances the overall efficiency of the printing process. Buyers, especially those in industries relying on high-volume production, should prioritize printers that come with user-friendly maintenance features. This includes easy access to components that require routine checks and replacements, such as print heads and build plates.

Support from manufacturers plays a vital role in the lifespan of large 3D printers. When selecting a 3D printing system, it is essential to consider the availability of comprehensive support services, including prompt customer service, repair services, and online resources. A manufacturer that provides extensive documentation and tutorial videos can significantly aid users in troubleshooting common issues, thus reducing downtime. Furthermore, participating in user communities can provide additional insights and tips for effective maintenance practices, fostering a culture of shared knowledge among users.