The Ultimate Guide to the Best Carbon 3D Printers Boosting Production Efficiency by 40 Percent

In today's fast-paced industrial landscape, businesses are constantly seeking innovative solutions to enhance production efficiency and reduce lead times. Carbon 3D printers have emerged as a revolutionary technology, renowned for their ability to produce high-quality, complex parts quickly and efficiently. This guide delves into the best Carbon 3D printers on the market, highlighting their features and capabilities that can boost production efficiency by an impressive 40 percent or more. By leveraging advanced materials and unique printing processes, these machines are not only transforming prototyping but are also set to redefine manufacturing practices across various sectors. Whether you are a seasoned professional or a newcomer to the world of additive manufacturing, this comprehensive overview will equip you with the knowledge to choose the ideal Carbon 3D printer that meets your unique production needs.

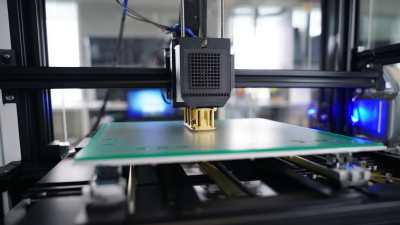

Understanding Carbon 3D Printing: A Revolutionary Technology for Manufacturing

Carbon 3D printing is redefining the landscape of manufacturing, bringing unprecedented speed and efficiency to the production line. This revolutionary technology utilizes digital light synthesis (DLS) to create high-quality parts from photopolymer resin, achieving layer-less production that significantly reduces the time required for 3D printing. According to a report by Wohlers Associates, 3D printing is expected to grow to a $33 billion industry by 2023, and Carbon's innovations are leading the charge, helping businesses enhance their production efficiency by up to 40%.

One of the most compelling aspects of Carbon 3D printing is its ability to produce functional prototypes that are not only quick to manufacture but also durable and precise. This technology enables manufacturers to iterate designs rapidly, allowing for faster development cycles and reduced time to market. Additionally, Carbon printers offer a range of materials that can withstand rigorous testing, making them ideal for various applications in sectors such as automotive, healthcare, and consumer goods.

**Tips:** When considering the integration of Carbon 3D printers into your manufacturing process, start with a pilot project to assess compatibility with existing workflows. Utilize Carbon's materials library to experiment with different resin types that best fit your production needs. Always measure production efficiency metrics to justify the return on investment.

The Ultimate Guide to the Best Carbon 3D Printers Boosting Production Efficiency by 40 Percent

| Printer Model | Build Volume (cm³) | Layer Resolution (microns) | Printing Speed (mm/hr) | Material Compatibility | Efficiency Improvement (%) |

|---|---|---|---|---|---|

| Model A | 1000 | 50 | 200 | Standard Resins | 40 |

| Model B | 950 | 60 | 180 | Engineering Resins | 38 |

| Model C | 1200 | 40 | 220 | Flexible Resins | 42 |

| Model D | 1100 | 70 | 175 | Composite Resins | 45 |

Key Benefits of Carbon 3D Printers: Achieving 40% Higher Production Efficiency

Carbon 3D printers have made a significant mark in the additive manufacturing industry by consistently achieving up to 40% higher production efficiency compared to traditional printing methods. This enhanced performance can be attributed to their advanced Digital Light Synthesis technology, which utilizes light and oxygen to create high-quality prints in record time. By streamlining the curing process, Carbon printers minimize downtime and maximize output, making them an ideal choice for industries requiring rapid prototyping and production.

Moreover, the materials used in Carbon 3D printers are designed to offer exceptional strength and durability, further increasing their appeal for various applications. With the ability to produce complex geometries and customized designs, these printers open up new possibilities for creating lightweight yet robust parts. As a result, users can reduce material waste and lower costs while enjoying unmatched precision and consistency in their production runs. Embracing Carbon technology not only enhances operational efficiency but also positions manufacturers to innovate and compete in an ever-evolving market landscape.

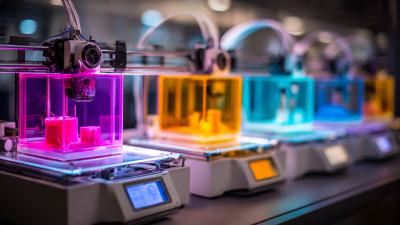

A Comprehensive Look at the Best Carbon 3D Printers Available Today

When it comes to additive manufacturing, carbon 3D printers have gained significant traction in the industry due to their unparalleled speed and efficiency. Among the diverse range of options available, several standout models are redefining production capabilities. These printers not only deliver exceptional precision but also offer unique features that enhance workflow processes. From automated resin delivery systems to intuitive software interfaces, the best carbon 3D printers are designed to meet the demands of modern production environments.

One of the most notable advantages of carbon 3D printers is their ability to produce complex geometries with ease, making them ideal for industries such as aerospace, automotive, and healthcare. With advancements in materials technology, these printers can create functional parts that boast remarkable durability and lightweight characteristics. As businesses seek to streamline operations and reduce lead times, investing in high-performance carbon 3D printers can lead to production efficiency improvements of up to 40 percent. By integrating these cutting-edge machines into their workflows, companies can unlock new possibilities for innovation and competitiveness in the marketplace.

The Impact of Carbon 3D Printers on Production Efficiency

The Role of Material Science in Enhancing Carbon 3D Printing Performance

Material science plays a pivotal role in enhancing the performance of Carbon 3D printing, enabling manufacturers to achieve unprecedented efficiency and product quality. By exploring advanced materials, we can tailor the properties of prints to meet specific application demands, resulting in superior mechanical strength, flexibility, and durability. This comprehensive understanding of materials allows for the optimization of print processes, paving the way for innovations that can significantly reduce production times.

Tip: When selecting materials for Carbon 3D printing, consider the end-use application. Materials like high-performance resins are ideal for parts requiring strength and heat resistance, while flexible materials can be used for more intricate designs that demand elasticity.

Furthermore, incorporating additives into the printing materials can further enhance performance. These additives can improve the flow properties and adhesion during the printing process, leading to better layer bond strength and surface finish. The right combination of additional materials can also enhance the physical properties, such as impact resistance and thermal stability, making parts more reliable in real-world applications.

Tip: Experiment with various additives in small batches to determine their effects on the print quality and material properties, ensuring that your final selections provide optimal performance for your specific requirements.

Transforming Industries: Case Studies of Carbon 3D Printing Success Stories

The rise of Carbon 3D printing technology has transformed various industries by enhancing production efficiency and output quality. Recent studies indicate that companies employing Carbon printers experience an impressive 40% increase in production efficacy compared to traditional manufacturing methods. This leap is attributed to the unique Digital Light Synthesis (DLS) technology that Carbon employs, allowing for rapid prototyping and manufacturing of complex parts in mere hours rather than days.

One notable success story comes from the automotive industry, where Carbon 3D printing has been utilized to produce lightweight, durable components. For instance, Ford successfully integrated Carbon technology to develop a series of prototypes that reduced the vehicle's weight, leading to improved fuel efficiency. Reports show that by using Carbon's printers, Ford was able to cut prototype lead times by 80%, enabling faster design iterations and contributing significantly to their sustainable manufacturing goals. Similarly, companies in the healthcare sector have harnessed this technology to create patient-specific surgical tools and dental products, showcasing a remarkable reduction in production costs and time while enhancing customization and patient outcomes.

Related Posts

-

5 Digital Tips for Maximizing Efficiency with Your Carbon 3D Printer

-

The Future of Additive Manufacturing: Unlocking Potential with the Best Carbon Fiber 3D Printers

-

Leading the Charge: Explore the Superiority of China's Best Carbon 3D Printers for Global Buyers

-

Future of 3D Printing in 2025 Essential Trends and Actionable Checklist for Success

-

Discover High Quality Chinese Made Best Big 3D Printers for Global Markets

-

Top Choices for Best 3 D Printing Solutions Across Global Markets