Exploring the Unique Features and Uses of the Best Small 3D Printer and How to Choose the Right One

The demand for small 3D printers has surged significantly in recent years, revolutionizing various industries from education to healthcare. According to a report by MarketsandMarkets, the global 3D printing market is projected to reach USD 34.8 billion by 2026, growing at a compound annual growth rate (CAGR) of 21.0%. This rapid expansion highlights the versatility and practicality of small 3D printers, which are increasingly being utilized for prototyping, customized manufacturing, and even educational tools.

These compact devices not only make 3D printing accessible to small businesses and hobbyists but also cater to large industries by enabling on-demand production and reducing lead times. As we explore the unique features and applications of the best small 3D printers, it is essential to understand how to choose the right model that aligns with specific needs, ensuring efficiency and innovation in a competitive landscape.

Key Considerations for Selecting the Best Small 3D Printer for Your Needs

When choosing the best small 3D printer for your needs, several key considerations must be kept in mind. First, evaluate the applications for which you plan to use the printer. Are you looking to create intricate models, functional prototypes, or artistic pieces? Understanding your intended use will help you select the right features, such as build volume and precision. For example, a printer with a larger build volume might be necessary for creating sizable prototypes, while detailed work may require higher resolution capabilities.

Next, consider the types of printing materials you'll need. Different printers support various materials, from basic plastics to advanced composites. Additionally, features such as multi-color printing, automatic bed leveling, and resume printing after a power outage can significantly enhance your printing experience. As the SLS 3D printing market continues to expand, projected to reach $2.81 billion by 2032, investing in a printer that aligns with both your current needs and future possibilities will ensure you remain at the forefront of 3D printing innovations.

Understanding the Unique Features of Small 3D Printers: A Comprehensive Guide

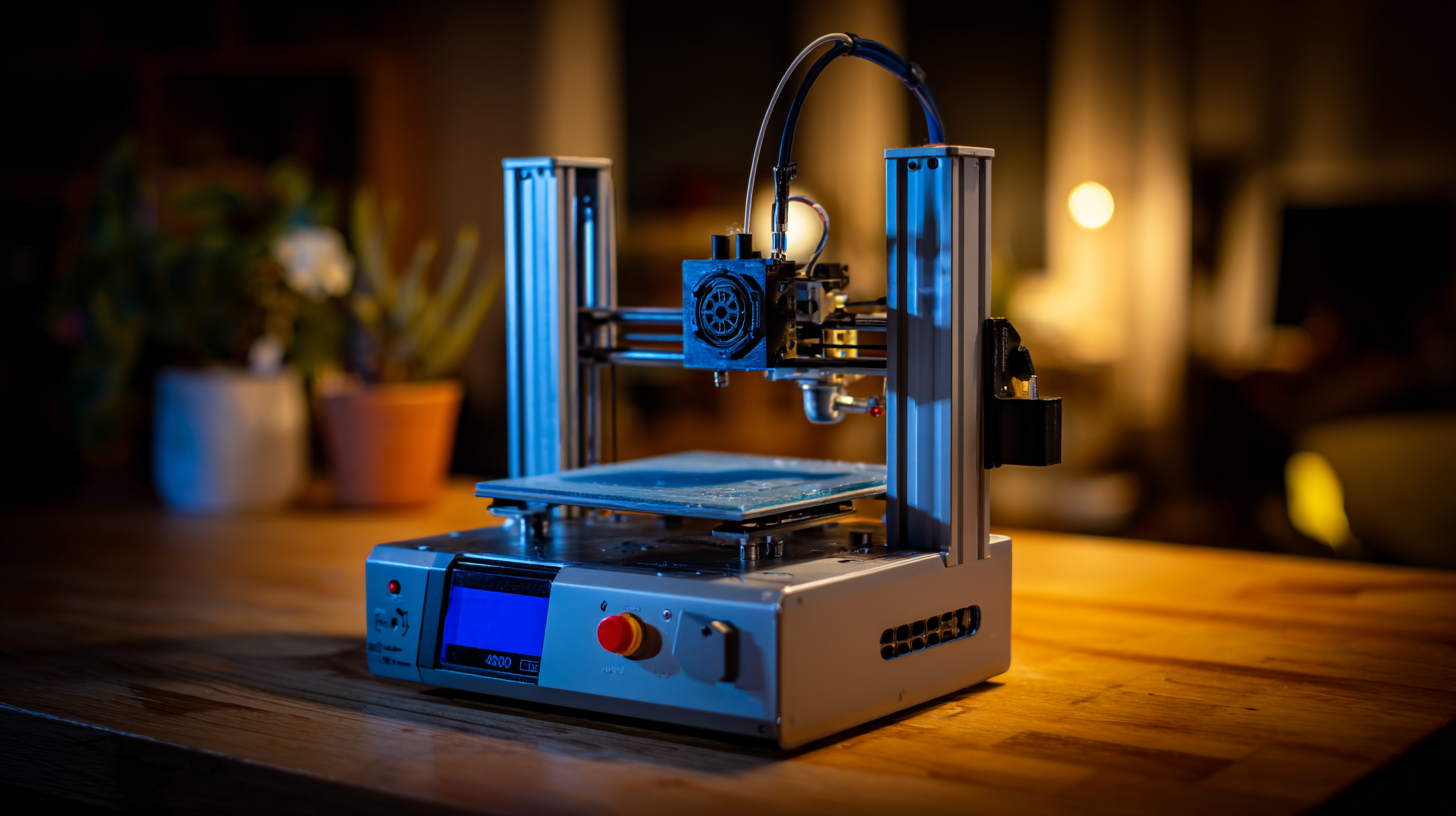

When considering small 3D printers, it’s essential to understand the unique features that set them apart from larger models. One of the primary advantages is their compact size, which makes them ideal for home use, small workspaces, or educational environments. Many small 3D printers are designed for easy setup and operation, featuring user-friendly interfaces that cater to beginners and experienced users alike.

Additionally, they often support a variety of materials, such as PLA and PETG, which can expand your creative possibilities without requiring advanced technical knowledge.

Additionally, they often support a variety of materials, such as PLA and PETG, which can expand your creative possibilities without requiring advanced technical knowledge.

Another unique feature of small 3D printers is their affordability, making them accessible to hobbyists and startups looking to enter the world of 3D printing without significant financial investment. Some models come equipped with advanced technology like auto-bed leveling, which simplifies the printing process and enhances print quality. Moreover, many compact printers are designed with portable capabilities, allowing users to take them on the go or store them easily between uses. This versatility is perfect for those seeking to experiment and innovate with their 3D printing projects. Understanding these features can play a crucial role in choosing the right small 3D printer to suit your specific needs and projects.

Exploring Innovative Uses of Small 3D Printers in Various Industries

Small 3D printers have revolutionized various industries, providing innovative solutions that cater to specific challenges. In the automotive sector, for instance, it has been reported that 75% of manufacturers are now using 3D printing to create prototypes and production tools, significantly reducing lead times and costs. The ability to swiftly produce small-scale parts allows companies to test and iterate designs quickly, leading to more efficient production cycles.

In the medical field, small 3D printers can create custom prosthetics and dental implants tailored to individual patients. According to a report by SmarTech Analysis, the medical 3D printing market is projected to reach $2.4 billion by 2026, emphasizing the growing demand for personalized solutions. This technology provides not only improved patient outcomes but also reduced material waste and time saved in manufacturing.

**Tip:** When selecting a small 3D printer, consider the specific materials you plan to use. Different printers support various filament types, which can influence the final product's strength and accuracy.

Additionally, evaluate the printer's resolution and layer height, as these factors critically determine the quality of your prints, especially for intricate designs or functional parts.

Exploring the Unique Features and Uses of the Best Small 3D Printer and How to Choose the Right One

| Feature / Use | Description | Industry/Application |

|---|---|---|

| Compact Size | Designed to fit in small spaces while maintaining print quality. | Home Users, Small Tech Startups |

| Affordable Pricing | Cost-effective without compromising essential functionalities. | Education, Hobbyists |

| User-Friendly Interface | Simplified setup and operation, often with touchscreen controls. | Education, Art Projects |

| Versatile Material Compatibility | Ability to print with various filament types, including PLA, ABS, and TPU. | Prototyping, Product Design |

| High Resolution | Produces fine details with a layer resolution often as low as 50 microns. | Medical Devices, Jewelry Design |

| Rapid Prototyping | Allows for quick iterations of designs for testing and feedback. | Engineering, Product Development |

| Educational Tools | Used to teach students about design, engineering, and technology. | Schools, Universities |

Comparing Popular Small 3D Printer Models: Features and Specifications

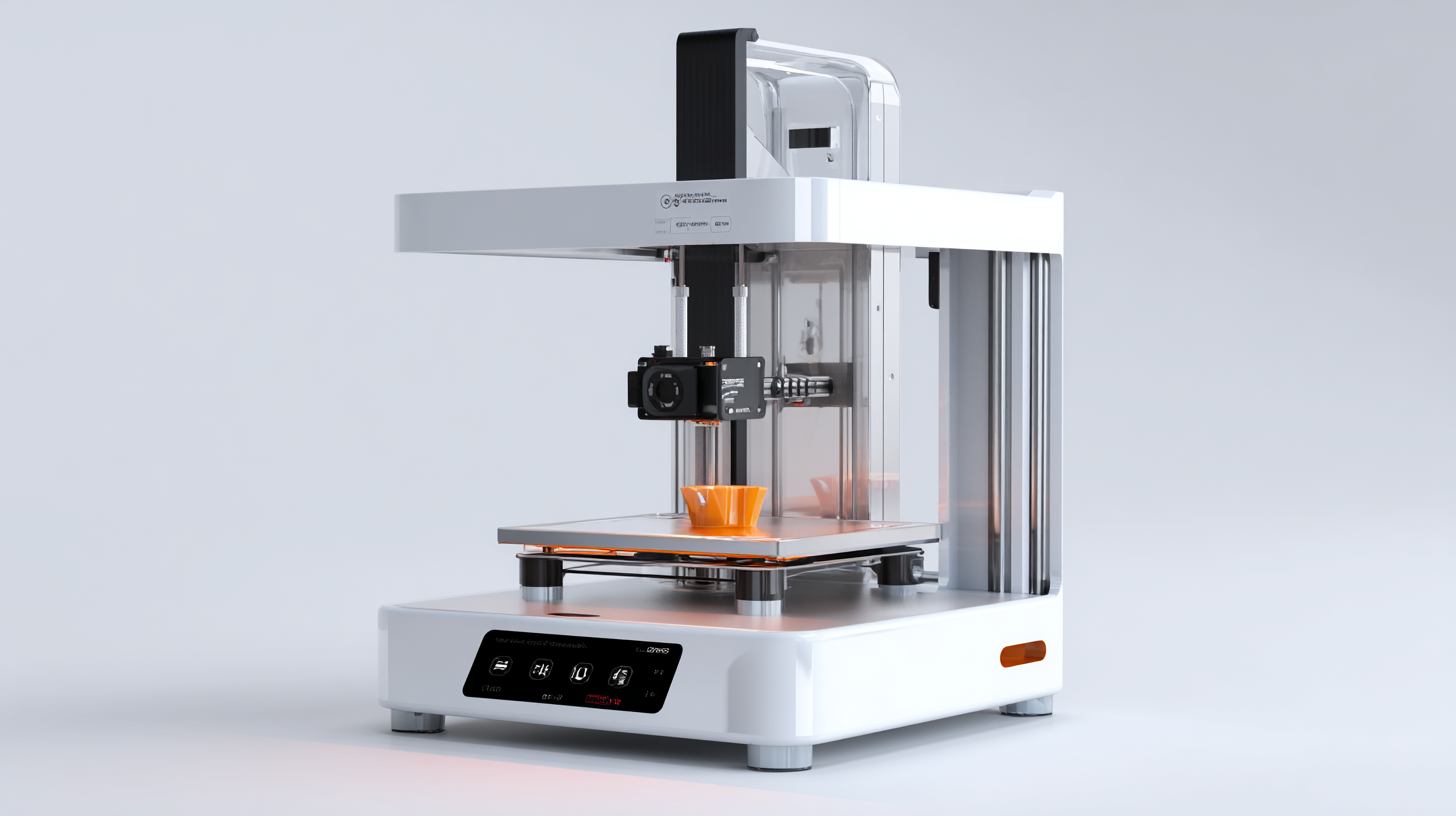

When exploring the landscape of small 3D printers, it's essential to compare popular models based on their features and specifications. Recent industry reports indicate that the small 3D printer market is projected to grow at a CAGR of 25.8% from 2022 to 2027, emphasizing the increasing demand for compact and efficient printing solutions. In this competitive arena, models like the Creality Ender 3 and Prusa Mini stand out, offering high print quality and user-friendly interfaces, appealing to both hobbyists and professionals.

The Creality Ender 3 features a build volume of 220 x 220 x 250 mm, a heated bed, and the capability to print with various filament types, making it a versatile choice for creators.

Meanwhile, the Prusa Mini, with its 180 x 180 x 180 mm build volume, integrates smart features such as automatic bed leveling and a removable magnetic print sheet, which significantly enhances usability.

These specifications highlight the importance of understanding each model's capabilities in relation to your specific printing needs, whether for prototyping, educational purposes, or product development, ensuring you choose the best small 3D printer to suit your requirements.

Tips for Maintenance and Troubleshooting Your Small 3D Printer

Maintaining your small 3D printer is crucial for ensuring optimal performance and longevity. Regular maintenance starts with cleaning the printer, particularly the nozzle and build plate, to avoid any buildup that can affect print quality. Use a soft cloth to wipe down external surfaces and a specialized cleaning solution for the nozzle. Additionally, checking and replacing worn-out parts, such as the filament feed mechanism and belts, can prevent unexpected printing issues. Keeping a maintenance log to track usage and service dates can also help you stay ahead of potential problems.

Troubleshooting common issues is an essential skill for any small 3D printer owner. If you experience adhesion problems, ensure the build surface is properly calibrated and that you are using the correct bed temperature for your filament. For filament jams, clear the nozzle and check the filament path for obstructions. If prints are coming out with poor quality, adjusting the print speed and layer height can often resolve those issues. Finally, don't hesitate to consult online communities and forums; they can be invaluable resources for tips and support from fellow 3D printing enthusiasts.